Introduction

Copper terminals are a fundamental component in electrical and electronic systems. Their superior conductivity, durability, and corrosion resistance make them an indispensable choice for various industries, including automotive, aerospace, industrial machinery, and home electrical installations. This article will explore the critical aspects of copper terminals, including their advantages, different industry applications, and best practices for installation and maintenance.

Why Copper Terminals Matter in Electrical Systems

Copper terminals provide a reliable and efficient connection between electrical components and conductors. Unlike other materials, copper’s low resistance ensures minimal energy loss, making it the preferred choice for high-performance electrical networks. Key reasons why copper terminals are essential include:

Exceptional Conductivity: Copper allows efficient current flow, reducing voltage drop and energy waste.

Long-Term Durability: Copper’s resistance to oxidation and environmental factors ensures prolonged service life.

High Load Handling Capacity: Copper terminals can withstand high electrical loads without overheating or degradation.

Versatility: Available in multiple designs and configurations, they accommodate various installation needs.

Industry Applications of Copper Terminals

1. Automotive and Transportation

Copper terminals play a critical role in vehicle wiring, battery connections, and ignition systems. They help maintain reliable electrical pathways in cars, trucks, motorcycles, and even electric vehicles (EVs).

2. Aerospace and Defense

Aircraft and military equipment rely on copper terminals for dependable electrical connections. The aerospace industry demands precision and durability, making copper a preferred material.

3. Industrial Machinery and Automation

Factories and automated systems use copper terminals for power distribution, motor control, and robotics. The high efficiency of copper helps maintain uninterrupted operations.

4. Renewable Energy Systems

Solar panels, wind turbines, and energy storage systems use copper terminals for optimal power transmission. Their resistance to extreme weather conditions enhances performance in renewable energy applications.

5. Home and Commercial Electrical Wiring

From circuit breakers to switchboards, copper terminals ensure safe and effective electricity distribution in residential and commercial buildings.

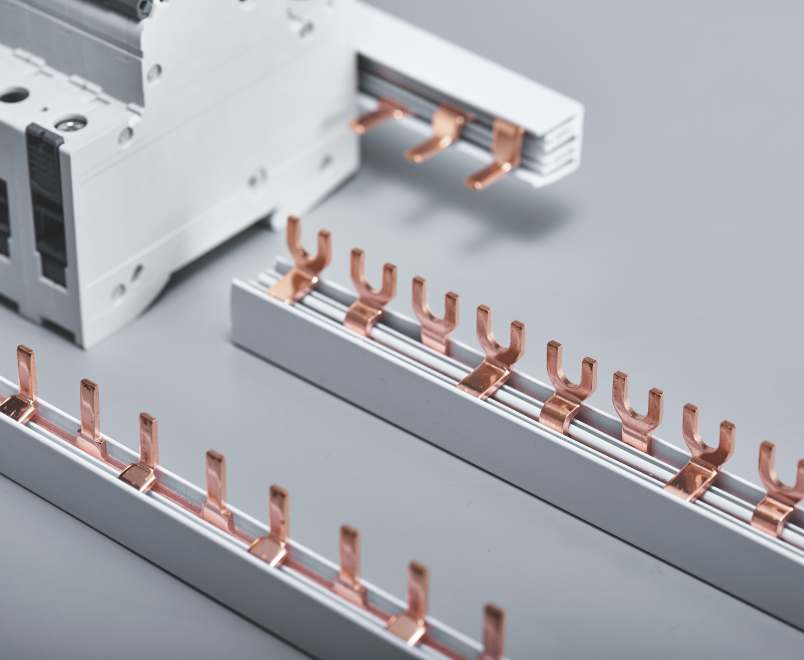

Types of Copper Terminals and Their Uses

Understanding the different types of copper terminals helps in selecting the best one for each application:

Ring Terminals: Provide secure connections in electrical panels and grounding applications.

Spade Terminals: Allow quick installation and removal without unscrewing entire connections.

Pin Terminals: Ideal for insertion into electrical blocks and terminals.

Butt Connectors: Used to join two wires while maintaining continuity.

Bullet Terminals: Enable quick-disconnect capabilities in automotive and industrial settings.

Flag Terminals: Designed for compact spaces with right-angle connectivity needs.

Installation Best Practices for Copper Terminals

To ensure optimal performance, it’s crucial to follow proper installation techniques:

1. Selecting the Right Terminal Size

Match the terminal size to the wire gauge to avoid loose connections or excessive resistance.

2. Crimping vs. Soldering

Crimping: Offers a strong mechanical bond with minimal resistance.

Soldering: Ensures a solid connection but may be less flexible in high-vibration environments.

3. Using Proper Tools

Quality crimping tools and heat shrink tubing enhance durability and safety.

4. Regular Inspection and Maintenance

Check terminals for signs of corrosion, wear, or looseness to prevent failures.

Conclusion

Copper terminals are the backbone of reliable electrical connections across various industries. Their superior conductivity, durability, and adaptability make them a trusted solution for high-performance electrical systems. By choosing the right type and following best installation practices, users can maximize efficiency and longevity in their electrical applications.

For further insights on copper terminals or expert recommendations, feel free to reach out!