Introduction

If you’re a solar distributor, EPC, or integrator, you’ve likely considered sourcing OEM or ODM PV combiner boxes. But which is the better option for your brand and business model?

Definitions

OEM (Original Equipment Manufacturer): You provide the design; the factory produces it under your brand.

ODM (Original Design Manufacturer): The factory offers its standard design, which you rebrand or slightly customize.

When to Choose OEM

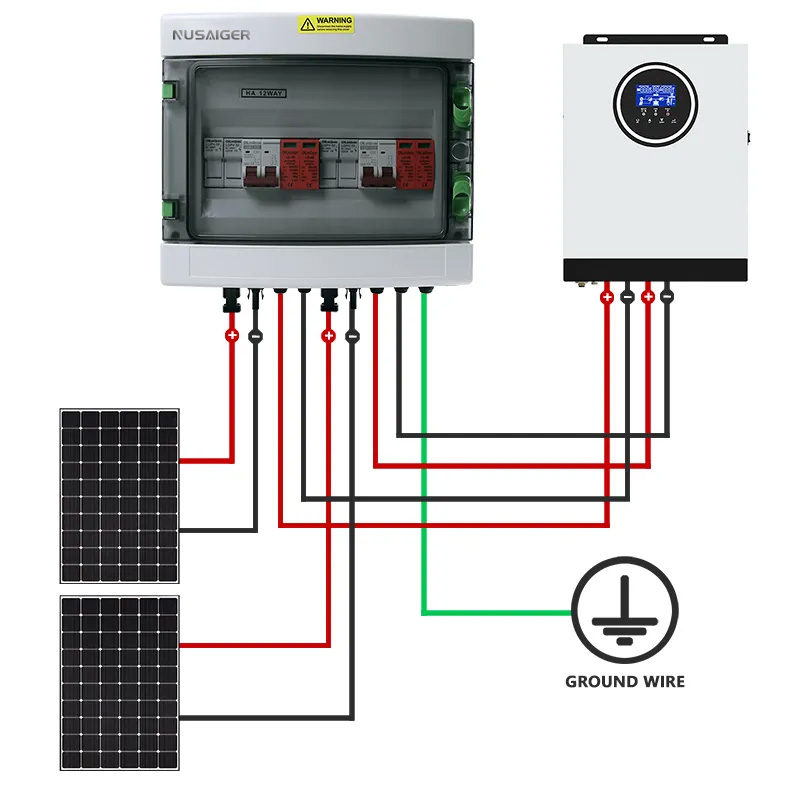

You have a unique system architecture

You want full control over materials, layout, and features

You need exclusive rights or patents

You’re targeting government or large-scale projects

When to Choose ODM

You want to start quickly with minimal R&D

You need small MOQs or faster lead times

You’re testing a new market

You prioritize price competitiveness

Customization Options

Branding/logo printing

Shell material and color

Number of input strings

Communication protocols (RS485, Ethernet)

Smart monitoring integration

Tips for Choosing a Reliable Supplier

Request factory certifications (ISO9001, UL, CE)

Visit the production line or request video proof

Check if fuses, SPDs, and breakers are branded

Evaluate after-sales service and customization flexibility

Conclusion

OEM and ODM both have their place in the solar supply chain. The right choice depends on your project scale, brand strategy, and time-to-market needs.