How to Properly Design and Install Busbars for Industrial and Commercial Systems

Busbars are an essential component of modern electrical distribution systems. Whether you are working in industrial plants, commercial buildings, or renewable energy setups, proper design and installation of busbars can greatly enhance system efficiency, safety, and longevity. This comprehensive guide takes you step-by-step through the entire process—from initial design concepts to final installation and testing.

1. Understanding the Role of Busbars

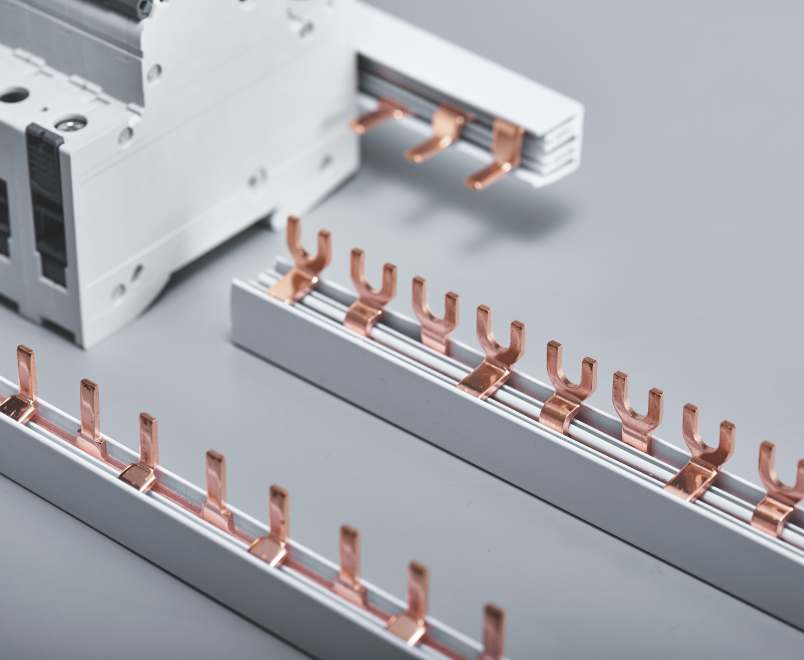

Busbars serve as conductive pathways that connect different components of an electrical system, allowing for efficient current distribution. They are preferred over traditional cables in many applications due to their higher current capacity, better heat dissipation, and ease of maintenance.

2. Initial Design Considerations

2.1 Load Assessment

Begin by accurately assessing the electrical load requirements. This includes peak current, expected load growth, duty cycles, and any transient conditions such as motor starts or fault currents. Accurately sizing the busbar starts with understanding the maximum continuous and short-term currents it must carry.

2.2 Material Selection

The two primary materials used for busbars are copper and aluminum. Copper offers higher electrical conductivity and better mechanical strength but at a higher cost. Aluminum is lighter and more cost-effective but requires a larger cross-sectional area and proper surface treatment to avoid oxidation.

2.3 Cross-Sectional Area Calculation

Using the load assessment, calculate the necessary cross-sectional area to ensure safe current carrying capacity and thermal performance. Standards such as IEC 61439 provide guidelines for these calculations. Factors such as ambient temperature, installation environment, and allowable temperature rise must be incorporated.

3. Thermal Management

Heat generated in busbars due to resistive losses must be managed to prevent insulation damage and maintain system reliability. Consider natural convection cooling, forced air or liquid cooling methods, and thermal sensors for continuous monitoring. Use thermal simulation tools to model heat distribution before finalizing the design.

4. Mechanical Design and Supports

Mechanical robustness is essential for busbars, especially in industrial environments with vibrations or seismic activity. Select appropriate support brackets, insulators, and expansion joints to allow for thermal expansion and minimize mechanical stresses.

5. Insulation and Safety Measures

Decide on the type of insulation based on voltage levels and environmental conditions. Options include PVC coatings, epoxy resin coatings, or insulated busbar trunking systems. Incorporate protective enclosures and grounding practices to enhance safety.

6. Installation Best Practices

6.1 Site Preparation: Ensure the installation area is clean, dry, and accessible. Verify that all components comply with design specifications before installation begins.

6.2 Handling: Use appropriate lifting equipment to prevent damage. Avoid bending or twisting busbars beyond manufacturer limits.

6.3 Mounting: Secure busbars firmly using recommended support hardware. Maintain proper spacing and clearances to avoid arcing.

6.4 Connections: Tighten bolted connections to manufacturer-specified torque to prevent resistance build-up.

6.5 Testing: Perform insulation resistance tests, continuity checks, and thermal imaging scans post-installation.

7. Compliance and Standards

Follow relevant international and local standards such as IEC 61439, UL 857, and IEEE guidelines to ensure system safety and interoperability. Documentation and quality assurance during installation are critical for compliance audits.

8. Maintenance and Troubleshooting

Regular inspection of busbars can prevent downtime. Look for signs of overheating, corrosion, mechanical wear, or loose connections. Use infrared thermography for non-invasive heat monitoring. Clean contacts and tighten connections as needed.

9. Case Studies

Review real-world examples where optimized busbar design and installation improved performance and reliability in factories, data centers, and renewable energy plants.

10. Emerging Technologies

Innovations such as smart busbars with embedded sensors and IoT integration are transforming power distribution with real-time diagnostics and predictive maintenance capabilities.

Conclusion

Designing and installing busbars correctly is a complex but rewarding process that significantly impacts electrical system performance. By following systematic steps and adhering to industry best practices, you can build a safe, efficient, and future-proof electrical distribution network.

FAQs

- What factors influence busbar size selection?

- Current load, temperature ratings, ambient conditions, and fault current withstand capacity.

- Can busbars be retrofitted into existing systems?

- Yes, with proper planning and compatibility checks.

- How often should busbar inspections be conducted?

- At least annually or as per manufacturer recommendations.

- Are busbar trunking systems more expensive than cables?

- Initial costs are higher but total life-cycle costs are often lower.

- What safety certifications should busbar systems have?

- Compliance with IEC, UL, and local electrical safety standards is essential.