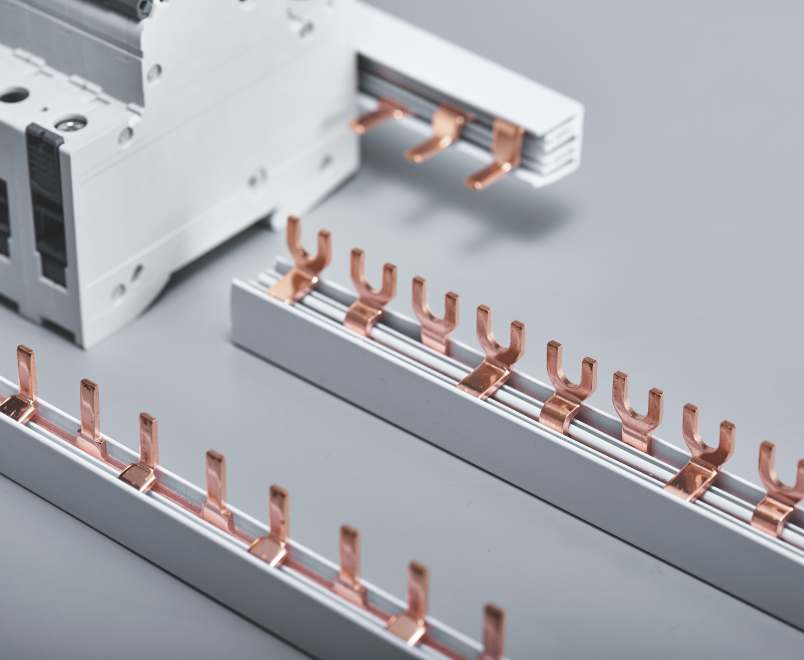

Comparing Copper and Aluminum Busbars: Pros, Cons, and Applications

Choosing the right material for busbars is crucial in any electrical design. The most common materials used are copper and aluminum, each with its own set of advantages and disadvantages. This article explores the critical differences between these two materials to help engineers and facility managers make informed decisions.

1. Electrical Conductivity

Copper has higher electrical conductivity (approximately 58 MS/m) compared to aluminum (about 36 MS/m). This means copper busbars can carry more current through a smaller cross-sectional area, making them ideal for space-constrained applications.

2. Cost Efficiency

Aluminum is significantly cheaper than copper, offering a cost-effective solution for large-scale installations. However, the lower conductivity requires aluminum busbars to be physically larger to handle equivalent current loads.

3. Weight and Handling

Aluminum is lighter than copper, making it easier to handle, transport, and install, especially in overhead or high-rise applications where weight is a concern.

4. Corrosion Resistance

Copper has superior corrosion resistance and forms a protective oxide layer. Aluminum oxidizes more quickly and may require additional protection, such as anodizing or painting, especially in outdoor or humid environments.

5. Thermal Conductivity

Copper has better thermal conductivity, allowing for more efficient heat dissipation. This leads to improved lifespan and stability in high-load or high-temperature systems.

6. Mechanical Strength

Copper is more ductile and resistant to mechanical fatigue, making it more suitable for applications with dynamic mechanical loads or frequent maintenance requirements.

7. Oxidation and Connections

Aluminum requires anti-oxidation treatment and special connectors due to galvanic corrosion risks. Copper, on the other hand, allows for straightforward bolted or soldered connections.

8. Environmental Considerations

Aluminum is more abundant and has a lower environmental impact in terms of extraction, although both materials can be recycled efficiently. The lower weight of aluminum also reduces transportation emissions.

9. Application Suitability

- Copper: Used in data centers, high-current switchgear, marine systems, and railways.

- Aluminum: Common in commercial buildings, utility substations, and renewable energy systems.

10. Summary Table

| Parameter | Copper | Aluminum |

|---|---|---|

| Conductivity | High | Moderate |

| Cost | High | Low |

| Weight | Heavy | Light |

| Corrosion Resistance | Excellent | Good (with treatment) |

Conclusion

Both copper and aluminum have distinct advantages. The optimal choice depends on the specific requirements of the application, including current rating, installation environment, budget constraints, and maintenance plans.