Empowering Renewable Energy with Advanced Busbar Systems: A Comprehensive Guide

As the global push for clean energy intensifies, renewable energy systems are becoming more advanced and widespread. At the heart of these systems lies a critical yet often underappreciated component: the busbar. Whether integrated into solar farms, wind turbines, or hybrid systems, busbar systems are fundamental to ensuring safe, efficient, and scalable energy distribution. This article explores the indispensable role of busbars in renewable energy, delving into their structure, benefits, applications, materials, and evolving technologies.

1. What is a Busbar and Why It Matters in Renewable Energy

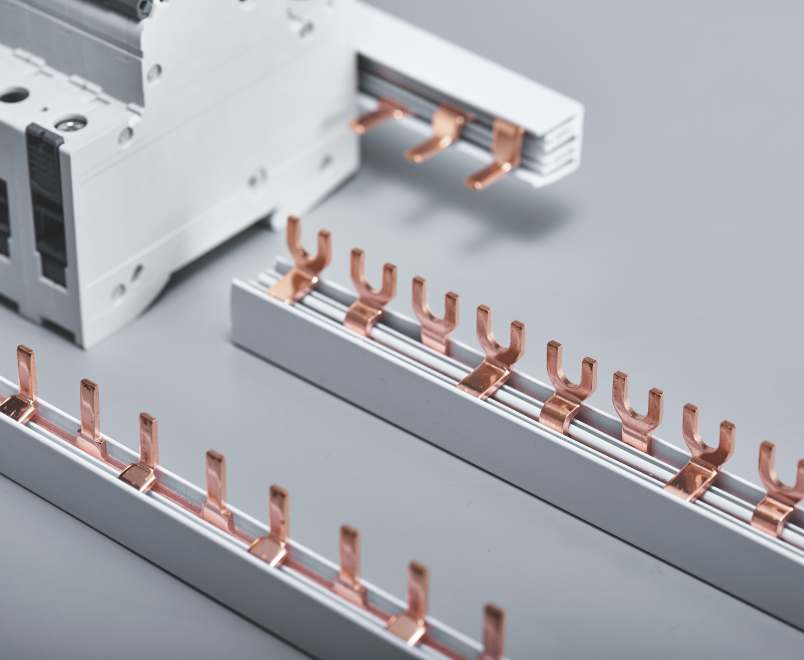

A busbar is a metallic strip or bar—usually made of copper, aluminum, or brass—that conducts electricity within a distribution board, switchboard, battery bank, substation, or other electrical apparatus. In renewable energy projects, busbars serve as key conduits that transport power from generation points (solar panels, wind turbines) to storage or distribution systems.

Unlike traditional cabling, busbars offer lower impedance, better heat dissipation, and higher durability—making them ideal for the high-demand, high-efficiency environments of modern renewable energy installations.

2. Key Applications of Busbars in Renewable Energy Systems

- Solar Power Plants: Busbars are used in photovoltaic (PV) panels to collect and transfer generated electricity. Inverters and combiner boxes also rely on busbars for distribution.

- Wind Farms: Busbars facilitate power transfer from turbine generators to substations, helping maintain stable voltage and minimize losses.

- Energy Storage Systems: In battery energy storage systems (BESS), busbars handle large currents during charge/discharge cycles.

- Hybrid Renewable Installations: Busbars help integrate solar, wind, and other energy types into a common grid or microgrid.

3. Advantages of Busbars in Sustainable Power Generation

Compared to traditional cable-based systems, busbars provide a range of advantages that align perfectly with the goals of renewable energy projects:

- Enhanced Safety: Enclosed busbar systems minimize the risk of short circuits, electric shocks, and arc flash incidents.

- Space Optimization: Their compact structure allows for neat layouts and reduced equipment room size.

- Scalability: Busbars support easy expansion, essential for modular solar farms or expanding wind arrays.

- Higher Efficiency: Reduced electrical losses mean more generated power is delivered to the grid.

- Maintenance Simplicity: Visual inspection and maintenance are easier due to open or accessible design options.

4. Types of Busbars Used in Renewable Projects

The specific type of busbar used depends on the installation scale and technical requirements:

- Flat Copper Busbars: Common in high-efficiency PV panels and inverters for their excellent conductivity.

- Insulated Sandwich Busbars: Used in compact wind turbine nacelles where vibration and weather resistance are critical.

- Flexible Laminated Busbars: Ideal for battery storage systems where movement and vibration tolerance are needed.

- Aluminum Busbars: Cost-effective for large installations with moderate current requirements.

5. Material Selection for Renewable Busbar Systems

Material choice plays a vital role in the performance and longevity of busbars in renewable energy applications:

- Copper: Offers superior conductivity and corrosion resistance but is heavier and costlier.

- Aluminum: Lighter and more affordable, suitable for high-volume installations where budget matters.

- Silver-plated or Tin-plated Busbars: Used in environments with high humidity or chemical exposure.

6. Busbar Integration in Photovoltaic (PV) Panels

Within a PV panel, thin busbars are printed or soldered onto the surface of solar cells to collect electrons generated from sunlight. As PV technology has evolved, designs have shifted from three-busbar (3BB) to nine-busbar (9BB) or even multi-busbar (MBB) configurations for better energy collection and minimized resistance.

7. Thermal Management: A Critical Design Factor

Renewable systems often operate under varying temperature conditions, making thermal performance critical. Busbars must dissipate heat efficiently to avoid losses and prevent overheating of connected components. This is why copper remains a preferred choice in high-load environments.

8. Busbar Design for DC and AC Distribution

Renewable systems use both DC (from panels or batteries) and AC (after inversion) power. Busbars are designed accordingly:

- DC Busbars: Heavier insulation and spacing requirements due to risk of arcing.

- AC Busbars: Require lower insulation and often operate in switchgear or control panels.

9. Environmental Considerations in Busbar Selection

Outdoor installations, such as wind farms or solar plants, expose busbars to UV radiation, temperature swings, humidity, and dust. Hence, robust coatings and insulation (epoxy, PVC, silicone rubber) are vital for ensuring long-term durability and reliable performance.

10. Trends and Innovations in Busbar Technology

- Smart Busbars: Integration of sensors to monitor current, temperature, and voltage in real time.

- Laser-Welded Multi-Layer Laminated Busbars: Enhance compactness and electrical integrity for high-density energy systems.

- Eco-Friendly Busbar Coatings: New developments in sustainable materials for insulation and encapsulation.

11. Compliance and Certification Standards

Renewable energy busbars must meet rigorous safety and quality standards, including:

- IEC 61439 (Low-voltage switchgear and controlgear assemblies)

- UL 891 / UL 508A (Industrial control panels)

- RoHS compliance (Restriction of hazardous substances)

12. Case Study: Busbar Systems in Utility-Scale Solar Farms

In a 200MW solar power installation in Southeast Asia, the developer used laminated copper busbars in all combiner boxes, central inverters, and switchgear enclosures. Results showed a 15% reduction in energy loss compared to traditional cable harnesses, faster deployment, and reduced maintenance downtime over 2 years.

13. Best Practices for Installing Busbars in Renewable Sites

- Ensure proper torque during connection to prevent overheating or loosening.

- Use insulating barriers between phases to avoid short circuits.

- Conduct routine thermal imaging scans to detect hotspots.

- Consider modular busbar systems for scalability in expanding farms.