Smart PV Combiner Boxes: How IoT and Monitoring Revolutionize Solar Management

The solar industry is rapidly evolving with digital technologies transforming how photovoltaic (PV) systems are designed, monitored, and maintained. Among these innovations, smart PV combiner boxes integrated with Internet of Things (IoT) technology and advanced monitoring systems are changing the game for solar asset management. This comprehensive article explores how these intelligent devices enhance performance, reduce downtime, and enable proactive maintenance across solar projects of all scales.

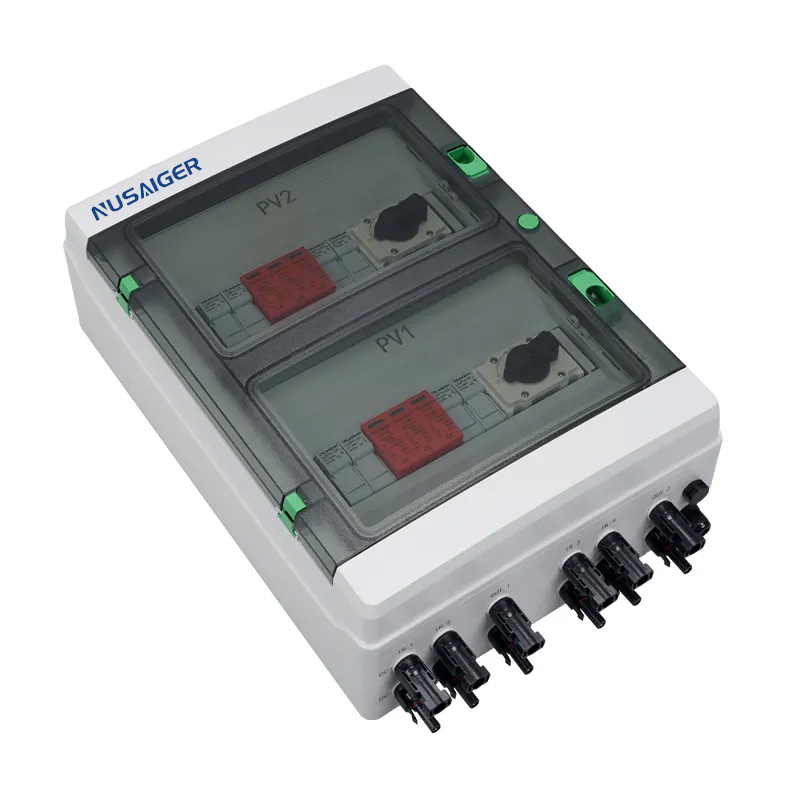

1. What is a Smart PV Combiner Box?

A traditional PV combiner box functions as a simple electrical junction consolidating multiple DC strings from solar panels into fewer outputs heading to inverters. In contrast, a smart PV combiner box incorporates sensors, communication modules, and embedded processing to provide real-time data on string-level performance, environmental conditions, and safety status.

- Integrated Sensors: Voltage, current, temperature, and insulation resistance sensors embedded for continuous monitoring.

- Communication Interfaces: Support for Modbus, RS485, Ethernet, or wireless protocols like LoRaWAN or NB-IoT.

- Embedded Processing: Onboard microcontrollers analyze data locally, filter noise, and generate alerts.

- Cloud Connectivity: Data is transmitted to cloud platforms enabling remote monitoring and analytics.

2. Benefits of IoT-Enabled Combiner Boxes in Solar Systems

2.1 Real-Time Performance Monitoring

Smart combiner boxes allow operators to monitor the current and voltage of each string in real-time. This granular visibility helps detect anomalies such as shading, soiling, or module degradation early.

2.2 Rapid Fault Detection and Localization

Instead of waiting for inverter alarms or periodic manual inspections, smart boxes instantly identify faulty strings or blown fuses. This dramatically reduces troubleshooting time and system downtime.

2.3 Predictive Maintenance

Analyzing historical performance data enables predictive analytics. Operators can forecast when components may fail or when cleaning is needed, optimizing maintenance schedules and reducing costs.

2.4 Enhanced Safety

IoT combiner boxes can monitor insulation resistance and temperature rise, providing early warnings of electrical faults or overheating, mitigating fire hazards.

2.5 Remote Accessibility

Technicians and asset managers can access combiner box data remotely via cloud dashboards or mobile apps, enabling off-site decision making and support.

3. Key Features of Smart PV Combiner Boxes

- String-Level Current and Voltage Sensors: Accurate measurement down to individual strings.

- Temperature and Humidity Sensors: Environmental data to assess potential failure risks.

- Integrated DC Disconnect Switch: Allows remote or automatic isolation of faulty strings.

- Surge Protection Devices (SPD): Monitored SPDs with status reporting.

- Communication Protocols: Support for open protocols enabling integration with existing SCADA or energy management systems.

- Data Logging and Alerts: Local storage of data and configurable alarms via SMS, email, or app notifications.

4. IoT Communication Technologies in Smart Combiner Boxes

Different communication technologies are used depending on the site infrastructure and data needs:

- Wired: Ethernet, RS485, Modbus TCP/IP offer reliable high-speed communication within facilities.

- Wireless: Cellular (3G/4G/5G), LoRaWAN, ZigBee, and NB-IoT enable flexible deployment in remote or large-scale solar farms.

- Hybrid Solutions: Combining wired and wireless for redundancy and coverage.

5. Implementation Considerations

5.1 Power Supply and Consumption

Smart combiner boxes require stable power supplies, often drawn from the solar array or external sources, to support sensors and communication modules.

5.2 Environmental Protection

IP65 or higher enclosures protect delicate electronics from dust, moisture, and UV exposure in outdoor installations.

5.3 Cybersecurity

Secure communication channels, encryption, and authentication protocols prevent unauthorized access and data tampering.

5.4 Integration with Existing Systems

Compatibility with inverter manufacturers’ monitoring platforms and third-party SCADA systems ensures seamless data flow.

6. Case Studies and Real-World Applications

6.1 Utility-Scale Solar Farms

Operators of multi-megawatt solar farms use smart combiner boxes to optimize energy yield, rapidly isolate faults, and comply with grid regulations requiring detailed monitoring.

6.2 Commercial Rooftop Installations

Businesses benefit from early detection of string issues that can reduce power output and increase costs, improving ROI.

6.3 Remote and Off-Grid Systems

Smart boxes with cellular or satellite communication enable monitoring in remote locations, critical for off-grid or hybrid solar applications.

7. Future Trends in Smart PV Combiner Boxes

- AI and Machine Learning: Enhanced analytics for anomaly detection and system optimization.

- Edge Computing: On-device processing reducing cloud dependency and latency.

- Integration with Energy Storage: Coordinated control between PV strings and batteries.

- Blockchain for Data Integrity: Secure and transparent logging of performance and maintenance records.

- Advanced User Interfaces: Augmented reality (AR) tools for maintenance and training.

8. Choosing the Right Smart PV Combiner Box

Considerations when selecting a smart combiner box include:

- Compatibility with system voltage and current ratings

- Availability of desired sensors and monitoring features

- Communication protocol support and network infrastructure

- Enclosure material and environmental ratings

- Vendor support, firmware update policies, and warranty

9. Installation Best Practices

- Ensure proper grounding and bonding

- Verify communication links during commissioning

- Configure alarm thresholds according to site-specific conditions

- Schedule regular firmware updates and system checks

- Train maintenance personnel on interpreting data and responding to alerts

10. Conclusion

Smart PV combiner boxes equipped with IoT and advanced monitoring capabilities are transforming solar power management. They empower operators with real-time insights, improve system safety, reduce maintenance costs, and maximize energy production. As solar installations grow in size and complexity, adopting these intelligent solutions becomes critical for optimizing performance and protecting investments.

Investing in smart PV combiner boxes today sets the foundation for a more connected, efficient, and resilient solar energy future.