What is a Busbar? A Comprehensive Guide for Electrical Systems

A busbar is a crucial component in power distribution systems. It acts as a central point where electric current is collected and distributed to various circuits. Busbars are essential in electrical panels, switchgear, substations, and other industrial or residential applications that require efficient and safe power distribution.

1. Introduction to Busbars

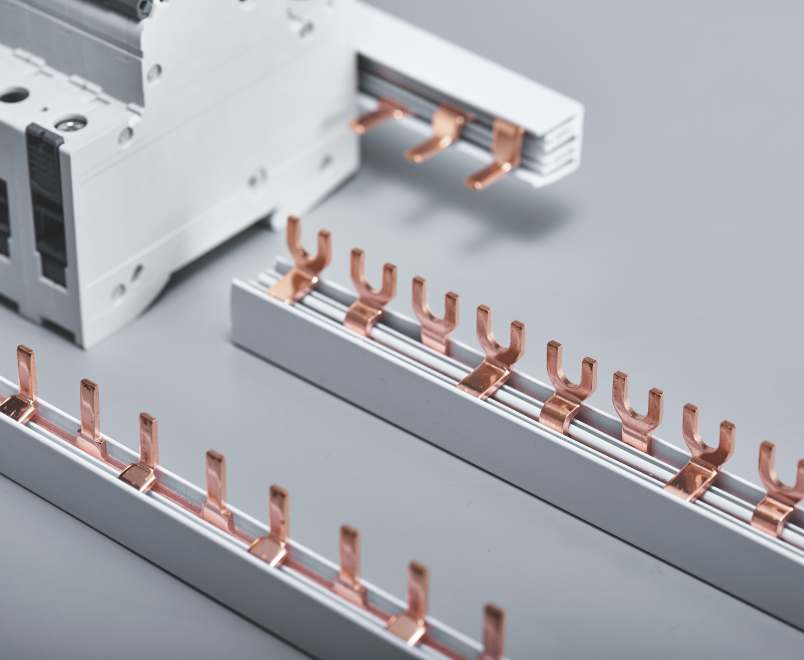

In the world of electricity, the term “busbar” refers to a metallic strip or bar made of copper, brass, or aluminum that conducts electricity within a switchboard, distribution board, substation, or other electrical apparatus. Its primary function is to carry large amounts of current safely and efficiently.

Busbars come in various shapes and sizes, including flat strips, solid bars, or hollow tubes, depending on the electrical and mechanical demands of the system. Their role is to minimize power loss, enhance safety, and simplify the layout of electrical systems.

2. History and Evolution

The concept of a centralized conductor has existed since the early days of electrical engineering. Early busbars were simply rods or wires connecting equipment. Over time, with the advancement in power systems and demand for higher reliability, modern busbar systems evolved with better materials, insulation, modularity, and safety mechanisms.

3. Why Use a Busbar?

Using a busbar instead of individual cables provides numerous benefits:

- Efficient space utilization

- Higher current-carrying capacity

- Lower voltage drops

- Reduced installation time and maintenance

- Improved safety and reliability

- Easy future expansions

4. Types of Busbars

Busbars can be classified based on various parameters such as material, shape, insulation, and application:

4.1 Copper Busbar

Copper busbars offer excellent electrical conductivity and thermal performance. They are corrosion-resistant and widely used in critical and high-performance systems.

4.2 Aluminum Busbar

Aluminum is lighter and more cost-effective than copper. Although it has slightly lower conductivity, it is suitable for many industrial and residential applications.

4.3 Insulated Busbar

These busbars come with an insulating layer to reduce the risk of short circuits and enhance safety in confined spaces. They are popular in compact panels and switchboards.

4.4 Flexible Busbar

Made from laminated layers or braided strips, flexible busbars are ideal for connections that require vibration resistance or movement.

4.5 Rigid Busbar

These are standard solid busbars used in fixed installations. They are strong, durable, and support high current loads.

5. Design and Configuration

Busbar design depends on factors like current rating, voltage level, mechanical stress, temperature rise, and environmental conditions. Engineers must ensure adequate spacing, insulation, and cooling to prevent overheating or electrical faults.

6. Applications of Busbars

Busbars are found in nearly all sectors involving electricity:

- Power generation plants: Used to distribute electricity from generators to transformers

- Substations: Act as junction points for switching and load balancing

- Data centers: Efficient power delivery with minimal losses

- Industrial machinery: Streamlined power connections within control panels

- Renewable energy systems: PV inverters and battery storage systems

- Commercial buildings: Electrical distribution across floors

7. Busbar vs Cables

While cables are flexible and easy to route, they have limitations in current handling and heat dissipation. Busbars provide better performance for high-power systems due to:

- Higher ampacity per unit area

- Lower inductance and resistance

- Neater and organized installation

- Improved fault current withstand capacity

8. Safety and Standards

Busbars must adhere to international standards such as IEC 61439, UL 857, and IEEE C37.23. Proper insulation, fault protection, and thermal design are essential for operational safety. Use of heat shrink sleeves, epoxy coatings, or air-insulated enclosures are common practices.

9. How to Choose the Right Busbar

When selecting a busbar system, consider the following:

- Current and voltage ratings

- Environmental conditions (humidity, dust, temperature)

- Space constraints

- Future expandability

- Installation method (horizontal, vertical, overhead)

- Material cost and availability

10. Maintenance and Troubleshooting

Regular inspections should focus on:

- Tightness of joints and connections

- Thermal imaging for hotspots

- Insulation integrity

- Signs of corrosion or discoloration

- Mechanical supports and vibration issues

11. Innovations in Busbar Technology

Modern busbar systems are becoming more compact, smart, and modular. Features include:

- Plug-and-play components

- IoT-enabled monitoring

- 3D-printed busbar supports

- Recyclable eco-friendly coatings

12. Conclusion

Busbars play a vital role in efficient power distribution. Whether for a high-voltage substation or a compact residential panel, choosing the right busbar solution can improve performance, safety, and reliability. As technology evolves, so does the importance of designing smarter, safer, and more sustainable busbar systems.