Maintenance and Safety of Busbar Systems

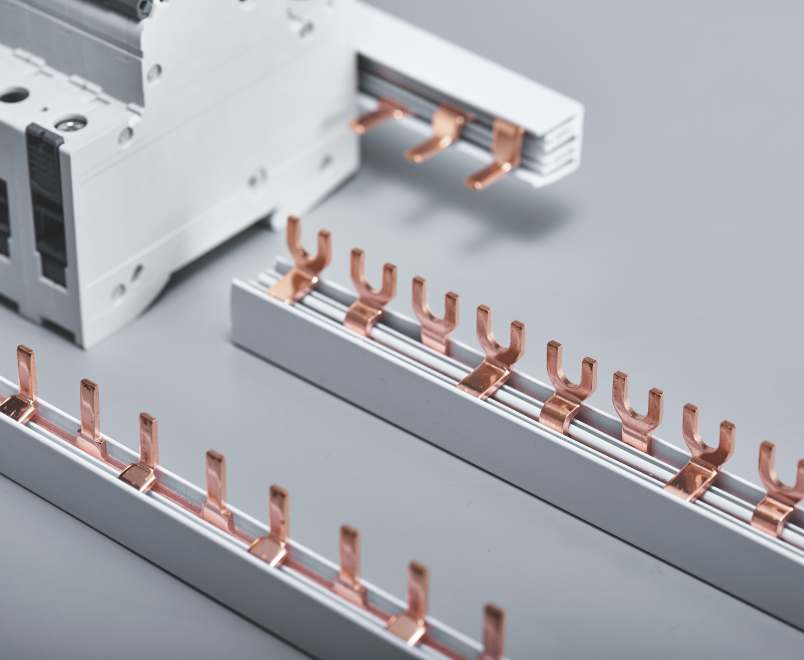

Busbar systems are at the core of reliable power distribution networks, but their effectiveness is only sustained through regular maintenance and strict adherence to safety protocols. This in-depth guide covers the inspection routines, testing methods, protective gear, and risk mitigation strategies essential to ensuring the long-term safety and performance of busbar installations.

1. Importance of Regular Maintenance

Neglected busbar systems can lead to serious consequences, including:

- Loose connections causing overheating

- Increased system losses due to corrosion or oxidation

- Arc flash incidents due to insulation failure

- Catastrophic faults during short circuits

Routine maintenance improves operational efficiency, extends system life, and minimizes unplanned outages.

2. Types of Busbar Maintenance

- Preventive Maintenance (PM): Scheduled inspections, cleaning, torque checks

- Predictive Maintenance (PdM): Thermal imaging, vibration analysis, sensor-based condition monitoring

- Corrective Maintenance: Repairs or replacements after identifying issues

3. Visual Inspection Checklist

Inspect the following regularly:

- Discoloration or burns on insulation

- Signs of arcing or pitting on joints

- Loosening of bolts and mechanical supports

- Signs of corrosion, especially in humid or marine environments

- Obstructions to airflow or heat dissipation

4. Thermal Imaging (IR Thermography)

Infrared scanning is one of the most effective methods for early fault detection:

- Identifies hotspots at joints and terminations

- Detects unbalanced load conditions

- Prevents arc flash incidents caused by loose connections

Best Practices:

- Capture thermal data under full load conditions

- Compare temperature readings with baseline images

- Re-inspect any area with a delta T > 20°C immediately

5. Torque and Joint Maintenance

Bolted joints must maintain proper torque for minimal resistance. Over time, vibration and thermal cycles can loosen connections. Steps:

- Use calibrated torque wrenches

- Apply anti-oxidation compound on joint faces

- Re-torque per manufacturer’s schedule (usually annually)

- Replace damaged or deformed washers and bolts

6. Cleaning and Dust Control

Dust and contaminants on busbars can cause surface tracking or corona discharge. Cleaning guidelines:

- De-energize before cleaning

- Use vacuum cleaner or dry, non-abrasive cloth

- Avoid solvents unless approved by the insulation manufacturer

- Install filtered ventilation to minimize airborne contaminants

7. Insulation Integrity Checks

Regular testing helps ensure insulation health:

- Megger (insulation resistance tester): Test at 500V–1000V for LV systems

- Dielectric withstand test: Confirms busbar can handle overvoltage

- Leakage current test: Detects insulation breakdown under load

8. Arc Flash Risk and Mitigation

Arc flash is a serious hazard caused by sudden energy discharge from a fault. Mitigation strategies include:

- Use insulated or enclosed busbar systems

- Maintain proper phase clearances

- Ensure joints are clean, tight, and oxidation-free

- Follow NFPA 70E and IEEE 1584 guidelines for incident energy calculation

9. Personal Protective Equipment (PPE)

Workers performing maintenance must wear appropriate PPE, including:

- Arc-rated clothing (Category 1–4)

- Voltage-rated gloves and sleeves

- Face shield or arc flash hood

- Insulated tools and safety shoes

10. Lockout/Tagout (LOTO) Procedures

Always follow proper isolation and tagging procedures:

- Shut down and isolate all energy sources

- Attach personal lock and tag with identification

- Verify zero energy state using test equipment

- Keep LOTO logs and ensure all team members are trained

11. Grounding and Bonding Inspection

Improper grounding can cause hazardous touch voltages or EMI issues. Ensure:

- Busbar systems are bonded to panel enclosure

- Protective Earth (PE) busbars are continuous and unbroken

- Ground resistance is within acceptable limits (typically <5 ohms)

12. Monitoring and Automation

- Install temperature sensors for thermal alerts

- Use current sensors (CTs) for load balancing

- IoT-based monitoring for remote diagnostics and predictive alerts

- SCADA integration for large-scale systems

13. Busbar Testing Frequency

Testing intervals depend on system criticality:

- Mission-critical facilities (e.g., data centers): Quarterly checks

- Industrial or commercial buildings: Semi-annual inspections

- Low-load or lightly used systems: Annual maintenance

14. Record Keeping and Compliance

Documentation helps track system health and compliance:

- Maintain logs of inspections, thermal images, test results

- Retain torque values and re-torque dates

- Ensure alignment with NFPA, OSHA, IEC, and local codes

15. Emergency Response Planning

- Train staff in electrical fire response and first aid

- Install arc fault detection systems

- Ensure accessibility of emergency shutoff switches

- Post hazard signage near live panels

16. Conclusion

Effective maintenance and safety practices are non-negotiable when it comes to busbar systems. Routine inspections, thermal imaging, torque checks, and the use of appropriate PPE all contribute to preventing downtime and protecting personnel. By embracing a culture of proactive maintenance and adhering to standards, facility managers and electrical engineers can ensure busbar systems operate at peak efficiency with minimal risk.

As busbar systems continue to evolve with IoT integration and modular designs, their maintenance will require not just physical tools, but digital monitoring and predictive analytics. Staying ahead of issues is the best way to keep power flowing safely and reliably.