Executive Summary: Copper terminals succeed or fail by context. This industry playbook maps environment-driven choices—from plating and insulation to torque and QC—so your projects pass audit, survive vibration and corrosion, and stay thermally stable under load.

Copper Terminals in Industry: Application Playbook for Automotive, Solar PV, Industrial Panels, Data Centers, Marine & Rail

1) Universal Principles for Any Industry

Match Conductor Class

Ensure the barrel fits the strand class (e.g., IEC Class 2/5/6). Fine-strand needs long barrels and multi-point crimps to pass pull and heat-rise tests.

Use Specified Dies

Crimp with the die index from the lug manufacturer; verify the emboss mark. “Looks good” is not a spec.

Control Interfaces

Clean pads, correct washer stack, and calibrated torque prevent micro-arcing and thermal runaway.

Seal the Joint

Adhesive-lined heat shrink prevents capillary moisture ingress—crucial outdoors, offshore, and in washdown plants.

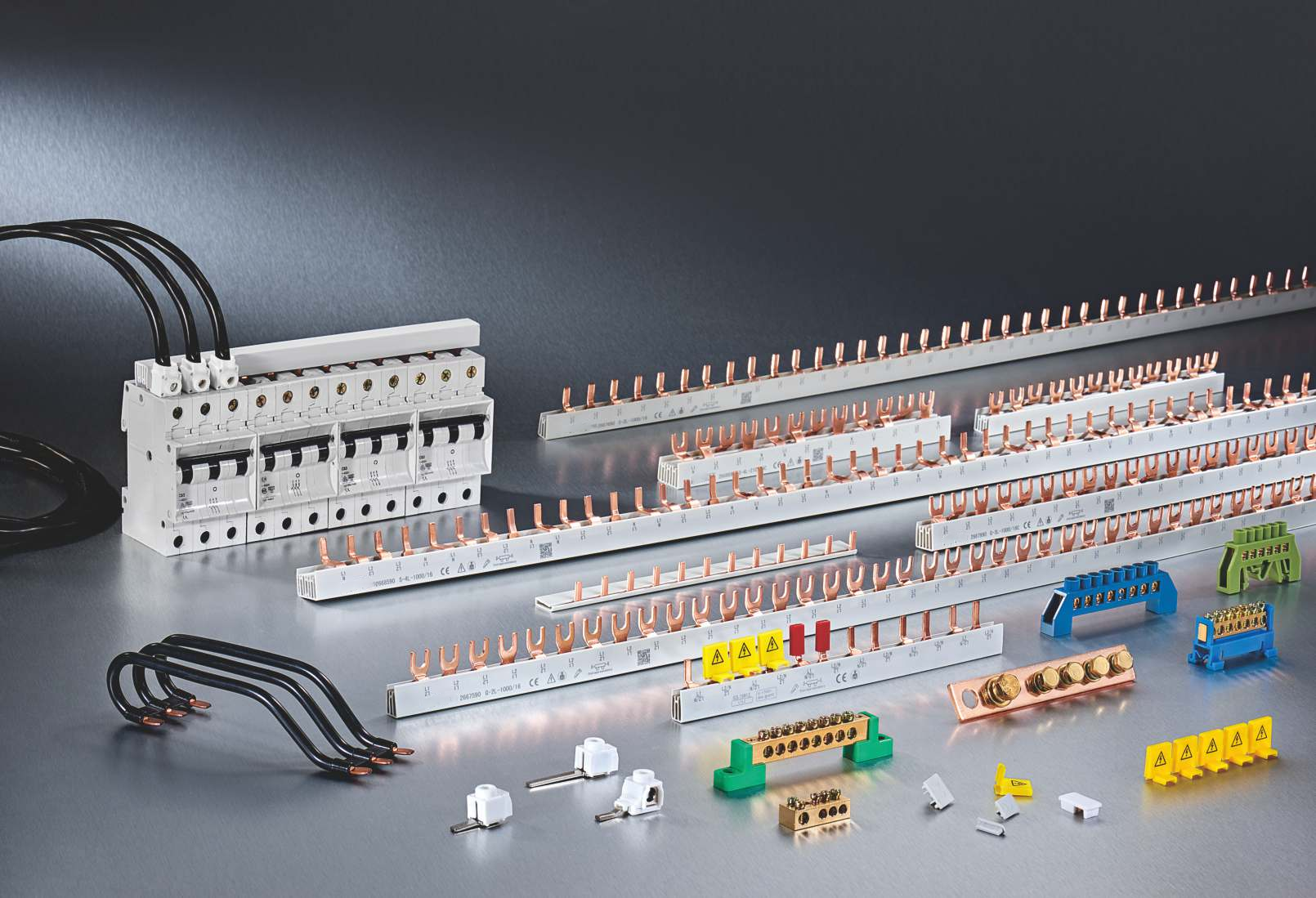

2) Application Matrix: Environment → Terminal Choice

| Environment / Sector | Recommended Terminal | Plating / Protection | Notes |

|---|---|---|---|

| Automotive (12–48V, vibration) | Compression lugs, ring/fork; long barrel for fine-strand | Tin-plated + adhesive-lined heat shrink | Record torque; use locking hardware; validate after shakedown. |

| Solar PV (DC strings & combiner) | Tin-plated copper lugs, PV-rated terminals | UV-resistant sleeves, adhesive-lined heat shrink | Thermal cycling: schedule IR scans at commissioning and seasonally. |

| Industrial panels & MCC | Compression lugs with inspection window | Bare or tin-plated (humidity dependent) | Derate in enclosed cabinets; follow busbar clearances. |

| Data centers (UPS/PDU/busway) | High-amp long-barrel lugs, multi-crimp | Tin-plated; label torque/ID | Thermal rise ≤ spec; use IR camera during load test. |

| Marine & offshore | Tin-plated or specialty plated copper | Sealed terminations; anti-wicking sleeves | Salt mist resistance & periodic re-torque essential. |

| Rail & transit | High-vibration rated, long barrel | Tin/silver plating per OEM | Documented pull test; locking hardware mandatory. |

Matrix is guidance; always follow equipment OEM and connector manufacturer documentation.

3) Automotive & Off-Highway

- Challenges: Vibration, temperature swings, fluids, and tight packaging.

- Spec Tips: Long-barrel compression lugs; tin-plating; adhesive-lined heat shrink; paint-mark torque.

- Process: Die index per chart, emboss verification, pull test sampling, shakedown re-check.

Pro move: label torque values on the lug flag or nearby harness tag for serviceability.

4) Solar PV & Energy Storage

- Challenges: UV, humidity, thermal cycling, DC arcing risks.

- Spec Tips: Tin-plated copper lugs; UV-rated sleeves; IR scans at 100% load if possible.

- Commissioning: Verify polarity, torque to OEM spec, record ΔT at lugs vs. ambient.

Avoid: Mixing AWG and mm² with “near fit” lugs—leads to hollow crimps and hotspots.

5) Industrial Panels & Switchgear

- Challenges: Enclosure heat, harmonics, dust, maintenance access.

- Spec Tips: Inspection-window lugs; correct washer stack; torque tool calibration log.

- Quality: Adopt pass/fail visuals (no flashing, centered emboss) and tensile sampling.

Add a lug map on the panel door listing wire size, lug type, torque, and inspection status.

6) Data Centers & Mission-Critical

- Challenges: High currents, redundancy paths, strict ΔT limits.

- Spec Tips: Long-barrel, multi-crimp; tin-plating; label and photo-document every termination.

- Validation: IR imaging during integrated systems test; trend temperatures over time.

Document “as-built” torque with operator ID/time stamp for audit readiness.

7) Marine, Offshore & Port Equipment

- Challenges: Salt fog, continuous vibration, ingress risk.

- Spec Tips: Tin-plated copper; sealed terminations; strain relief against cable whip.

- Maintenance: Scheduled re-torque; corrosion inspection; replace discolored/greenish joints immediately.

8) Rail & Transit Electrification

- Challenges: Shock/vibration cycles, temperature extremes, long service life.

- Spec Tips: High-vibration rated lugs; specified plating (tin/silver); locking hardware (e.g., Nyloc, Nord-Lock per OEM).

- QA: Pull test per batch; emboss/lot traceability mandatory.

9) Quality Control: From Crimp to Torque & IR Audits

Crimp Quality

Strip to barrel depth; die index per chart; emboss visible; no flashing; full conductor fill; multi-crimp for long barrels.

Torque & Hardware

Use OEM torque table; flat washer + spring washer if specified; avoid reaming tongue holes; paint-mark after torque.

Thermal Audit

IR scan at representative load; ΔT within spec; trend over seasons (PV) or after duty-cycle shifts (EV/ESS).

QC Pack: die chart • torque table • tensile sampling log • IR photos • as-built checklist

10) Printable Checklists

Pre-Install

- Wire size + strand class verified

- Barrel & stud size match; no reaming

- Plating per environment (tin default outdoors)

- Tool calibration within date

- Heat shrink (adhesive-lined) available

During Install

- Strip = barrel depth; no nicked strands

- Emboss mark checked; multi-crimp sequence

- Torque applied per OEM; paint-mark

- Label circuit ID & operator

Commissioning & Audit

- IR scan ΔT within limits

- Photos archived to job folder

- Re-torque schedule defined

- Nonconformities closed with evidence

11) Field-Proven Mini Case Studies

PV Rooftop Array

Seasonal ΔT spikes at two strings. Root cause: mixed AWG/mm² and single-crimp on long barrel. Fix: correct mm² lugs + dual-crimp + adhesive-lined sleeves. ΔT normalized <5°C.

Marine Crane

Greenish corrosion and intermittent alarms. Fix: tinned lugs, sealed terminations, re-torque plan post-swell operations. MTBF improved markedly.

Data Hall Busway

Hotspot on M10 joint during load test. Cause: underspecified torque. Fix: OEM torque table enforcement + paint marks + supervisor sign-off.

12) Frequently Asked Questions

Q1. Do I need silver plating?

Only for high-temperature or specific OEM requirements. Tin-plated copper covers most outdoor/industrial cases.

Q2. Can I reuse a compression lug?

No—compression lugs are single-use. Replace after removal to maintain gas-tight integrity.

Q3. What’s a quick health check?

Visual (no discoloration or melting), torque paint intact, and ΔT within limit under typical load.

13) Next Steps

Need a spec-ready datasheet or torque table? Grab these resources:

Copper Compression Lugs (2.5–240 mm²)

Termination QC Pack (Die chart + Torque + Forms)

This article is general guidance. Always follow the equipment and connector manufacturer documentation for ratings, torque, and test criteria.