How to Choose the Right Electrical Busbar for Your Application

Electrical busbars are critical components in modern power distribution systems. However, choosing the

right busbar is not always straightforward. Factors such as material, current capacity, operating

environment, and installation requirements all play a role in determining the most suitable option.

This guide will help you understand the key considerations when selecting an electrical busbar for

your specific application.

1. Determine the Electrical Requirements

The first step in choosing a busbar is to evaluate your electrical system’s requirements. Consider:

- Current Capacity: Busbars must handle the maximum load without overheating.

- Voltage Rating: Ensure the busbar can operate safely at the system’s voltage level.

- Short-Circuit Tolerance: Busbars must withstand potential fault currents.

Selecting the wrong size or type could lead to inefficiency, excessive heat, or even dangerous

electrical failures.

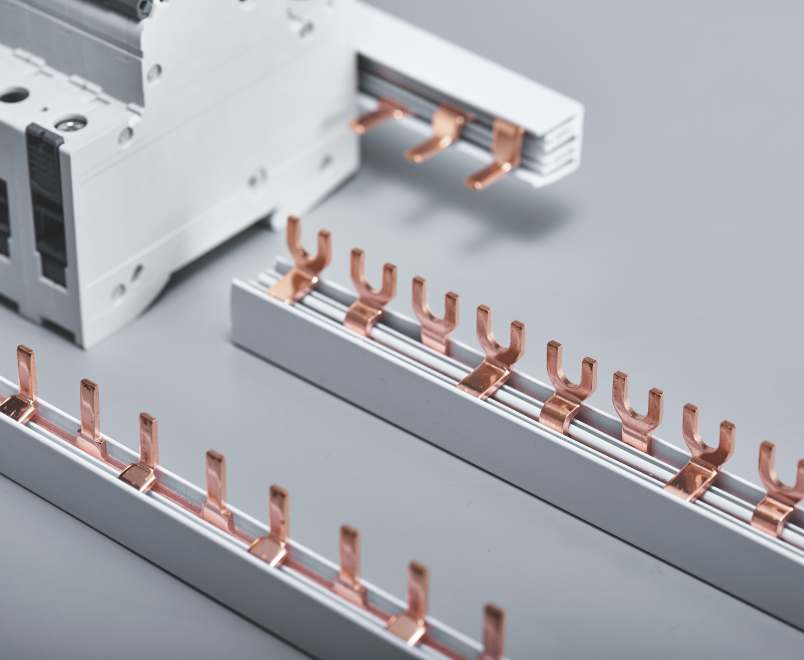

2. Material Selection: Copper vs. Aluminum

Busbars are typically made of copper or aluminum, and each has its pros and cons:

- Copper Busbars: Offer excellent conductivity, mechanical strength, and reliability.

Ideal for critical applications but more expensive. - Aluminum Busbars: Lightweight, cost-effective, and widely used in large-scale

installations. However, they require larger cross-sections to achieve the same conductivity as copper.

3. Consider Insulation and Coating

The operating environment often determines whether you need an insulated or coated busbar:

- Insulated Busbars: Safer for compact systems and reduce the risk of accidental

contact. - Tinned Copper Busbars: Provide excellent corrosion resistance, suitable for

humid or outdoor conditions. - Epoxy-Coated Busbars: Commonly used in high-voltage or high-humidity applications.

4. Mechanical and Environmental Factors

In addition to electrical characteristics, mechanical and environmental conditions should be

evaluated:

- Space Constraints: Compact designs may require flat or laminated busbars.

- Vibration: Flexible busbars are recommended in systems subject to vibration or

movement, such as transportation and renewable energy installations. - Temperature: Ensure the busbar material and insulation can withstand the ambient

and operating temperatures. - Corrosive Environment: Choose coated or tinned busbars to resist corrosion.

5. Compliance with Standards

Always check whether the busbar complies with relevant international standards such as IEC, UL, or

local electrical codes. Compliance ensures safety, reliability, and compatibility with other system

components.

6. Cost vs. Long-Term Value

While aluminum busbars may be cheaper upfront, copper busbars often provide better long-term value

due to their durability, lower maintenance, and efficiency. Consider both the initial investment and

the total cost of ownership when making a decision.

7. Practical Examples of Busbar Selection

- Data Centers: Copper busbars for high conductivity and reliability.

- Solar Power Plants: Tinned copper or aluminum busbars for outdoor performance.

- Industrial Panels: Insulated busbars for compact and safe power distribution.

- Automotive Applications: Flexible laminated busbars for vibration resistance.

8. Conclusion

Selecting the right electrical busbar requires a careful balance between technical requirements,

environmental conditions, and cost. By considering current capacity, material choice, insulation,

and compliance with standards, you can ensure that your system performs efficiently and safely for

years to come. Whether for industrial, commercial, or renewable energy applications, the right busbar

is a cornerstone of reliable power distribution.