Installation and Maintenance Guide for Electrical Busbars

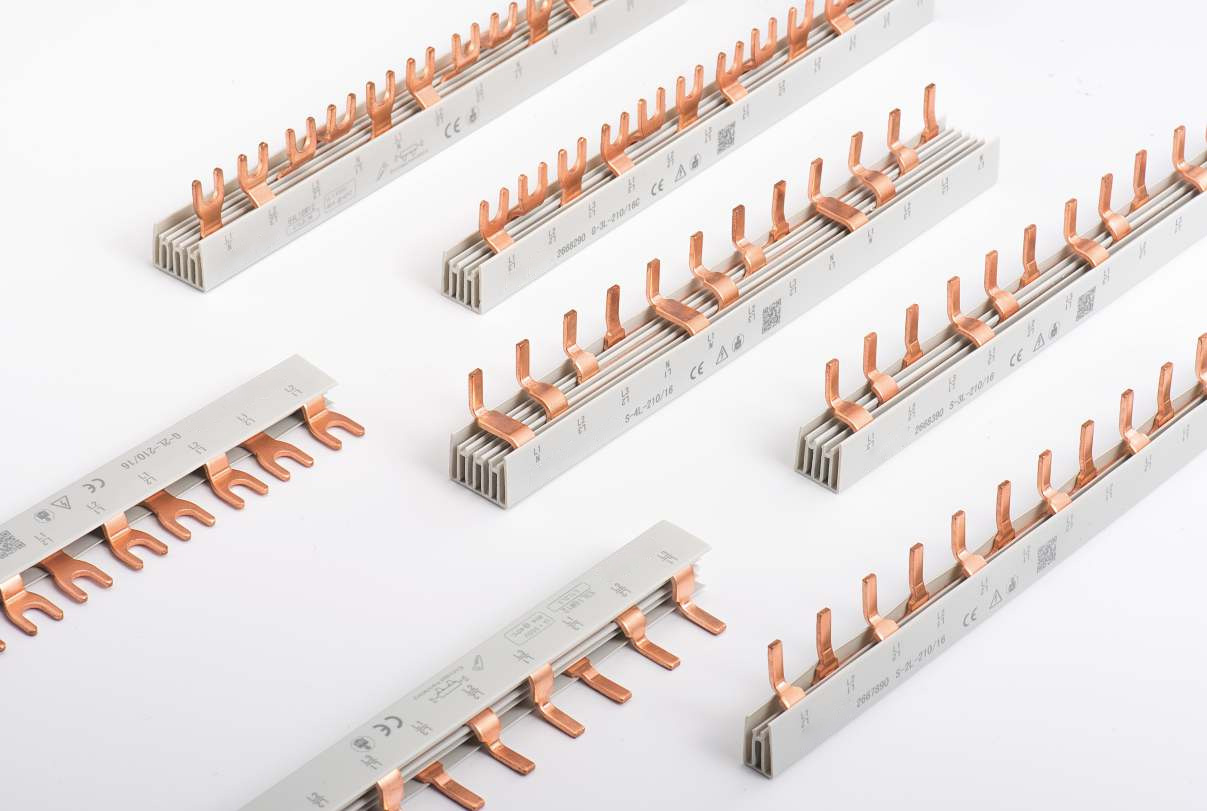

Electrical busbars are essential components for efficient power distribution in industrial, commercial,

and renewable energy systems. To ensure long-lasting performance and safety, proper installation and

regular maintenance are critical. This guide provides step-by-step instructions, safety recommendations,

and practical tips for handling electrical busbars effectively.

1. Pre-Installation Preparation

Before beginning the installation, thorough planning is necessary:

- Design Verification: Confirm busbar size, current rating, and insulation type

meet the project requirements. - Tools & Equipment: Prepare torque wrenches, insulating gloves, mounting brackets,

and protective gear. - Environment Check: Ensure the installation site is dry, clean, and free from dust

or corrosive substances.

2. Installation Best Practices

Following best practices during installation ensures reliability and reduces the risk of faults:

- Proper Alignment: Install busbars in straight, parallel runs to prevent stress

and uneven load distribution. - Tight Connections: Use calibrated torque tools to achieve secure but not

over-tightened connections. - Insulation: Apply insulation covers or sleeves to exposed parts for safety.

- Support Structures: Mount busbars firmly using brackets or clamps to minimize

vibration and mechanical stress. - Ventilation: Ensure adequate air circulation to avoid overheating.

3. Safety Considerations During Installation

Safety should always be the top priority:

- Turn off the power supply before installation or maintenance.

- Wear protective clothing, insulated gloves, and eye protection.

- Follow local electrical codes and international standards (IEC, UL, etc.).

- Use insulated tools to prevent accidental short circuits.

4. Common Installation Mistakes to Avoid

- Using undersized busbars that cannot handle the load.

- Failing to tighten connections to the recommended torque values.

- Improper insulation that increases the risk of arcing or electrical shock.

- Ignoring ventilation requirements, leading to overheating.

- Mixing copper and aluminum busbars without proper connectors, which causes galvanic corrosion.

5. Maintenance of Electrical Busbars

Regular inspection and maintenance extend the service life of busbars:

- Visual Inspection: Check for discoloration, cracks, or loose joints.

- Thermal Imaging: Use infrared cameras to detect hot spots caused by poor

connections. - Cleaning: Remove dust and debris regularly to maintain conductivity and prevent

overheating. - Torque Recheck: Periodically recheck bolt tightness according to manufacturer

specifications. - Corrosion Control: For outdoor or humid environments, ensure tin-coated or

epoxy-coated busbars remain intact.

6. Troubleshooting Common Issues

- Overheating: Caused by loose connections or undersized busbars. Solution:

re-tighten or upgrade busbars. - Corrosion: Common in humid areas. Solution: apply protective coatings or replace

with tinned copper busbars. - Vibration Damage: Use flexible busbars to prevent cracks in high-vibration

environments. - Electrical Arcing: Ensure proper insulation and spacing between conductors.

7. Conclusion

Proper installation and regular maintenance of electrical busbars are vital for ensuring efficient,

safe, and long-term performance in power distribution systems. By following industry best practices,

avoiding common mistakes, and implementing proactive maintenance, you can maximize the reliability

and lifespan of your busbar systems.