Busbar Systems Explained: Design, Types, and Applications

In modern electrical engineering, the busbar plays an indispensable role in distributing power safely and efficiently. From residential switchboards to industrial power distribution systems and renewable energy projects, busbars serve as the backbone of reliable electricity transmission. This article provides an in-depth exploration of busbar systems, including their design, types, applications, installation practices, and how to select the right busbar for your project.

1. What is a Busbar?

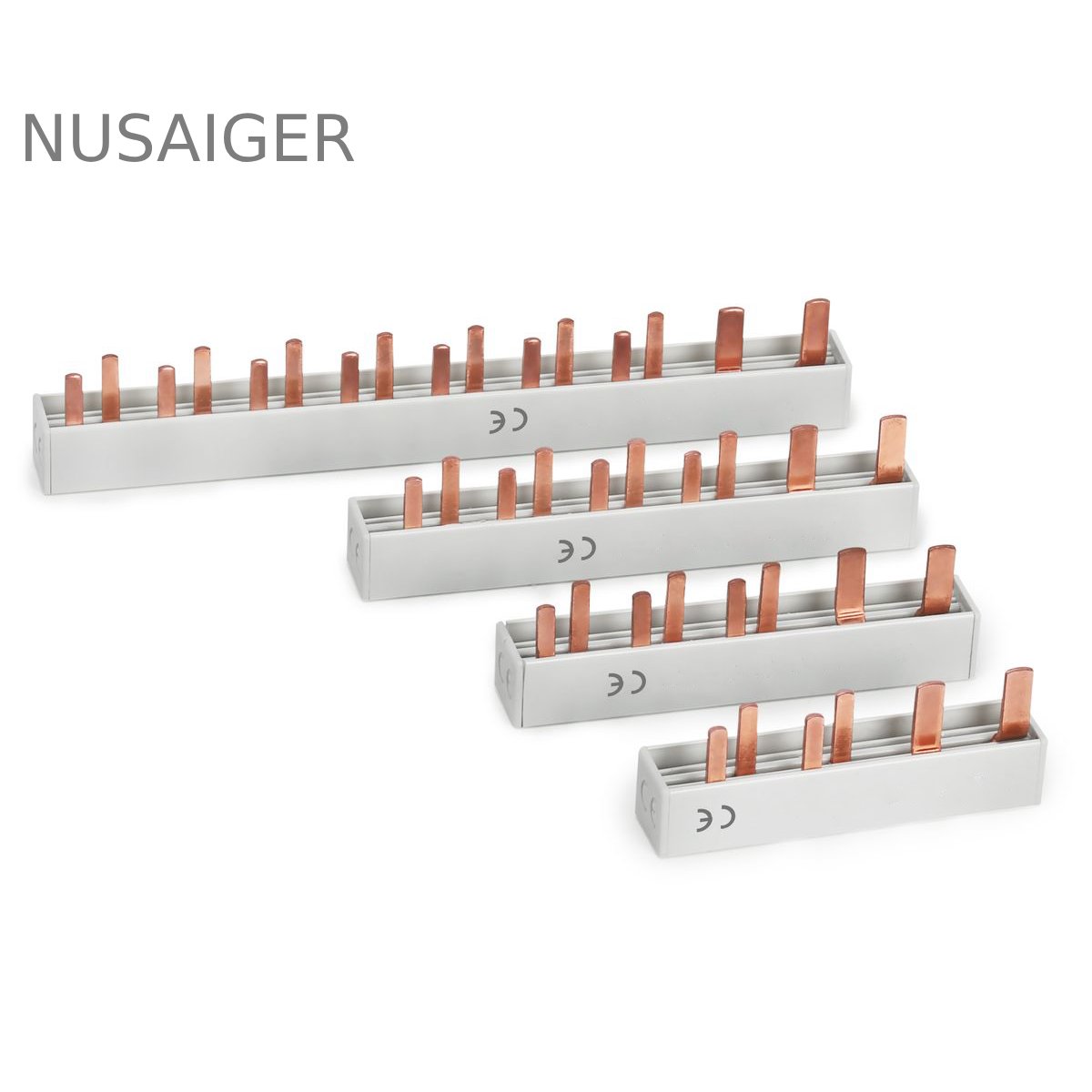

A busbar is a metallic strip or bar made of conductive material such as copper or aluminum, designed to carry large amounts of current. It serves as a common connection point for multiple electrical circuits. Instead of using bundles of wires, busbars simplify system design by allowing a central, rigid conductor that distributes current to various devices or panels.

Key Characteristics of Busbars

- Made from copper or aluminum due to their high conductivity

- Available in flat, rectangular, round, or hollow shapes

- Encased in protective insulation or installed in busbar trunking systems

- Customizable for low-voltage, medium-voltage, and high-voltage systems

2. Why Use Busbars Instead of Cables?

One of the most common customer questions is: “Why should I use busbars instead of multiple cables?”. The answer lies in efficiency, safety, and cost-effectiveness. Here are the main advantages:

- Higher efficiency: Busbars have lower resistance and better heat dissipation.

- Space-saving: Compact design compared to bundles of wires.

- Flexibility: Easy to modify, expand, or relocate in electrical systems.

- Safety: Reduced risk of overheating and short-circuits.

- Durability: Long lifespan with minimal maintenance.

3. Types of Busbars

Busbars come in various materials, shapes, and configurations, each suited to different applications:

3.1 Copper Busbars

Copper busbars are the most widely used due to their excellent electrical conductivity and mechanical strength. They are suitable for high-performance industrial systems, renewable energy projects, and critical power infrastructure.

3.2 Aluminum Busbars

Aluminum busbars are lighter and more affordable than copper. While their conductivity is lower, they are often chosen for large-scale installations where cost reduction is critical, such as power substations.

3.3 Insulated Busbars

These busbars are coated with epoxy or PVC insulation, offering enhanced safety in compact electrical panels or environments with high risk of accidental contact.

3.4 Flexible Busbars

Made from laminated copper strips, flexible busbars allow easier installation in tight spaces and provide vibration resistance, making them ideal for renewable energy inverters and electric vehicles.

3.5 Busbar Trunking Systems

These are prefabricated modular systems designed for distributing power across large facilities such as factories, shopping malls, and data centers. They allow easy installation, scalability, and improved load management.

4. Applications of Busbars

Busbars are used in a wide range of electrical systems. Some of the most common applications include:

- Residential & Commercial Buildings: Electrical panels, switchboards, and distribution boards.

- Industrial Facilities: Machinery, power distribution, and automation systems.

- Renewable Energy: Solar PV combiner boxes, wind power converters, and battery storage.

- Transport: Electric vehicles, railways, and aerospace power systems.

- Data Centers: High-efficiency power distribution with minimal downtime.

5. Busbar Design Considerations

Choosing the right busbar requires careful consideration of several factors:

- Current rating: The maximum current the busbar must handle.

- Material: Copper vs. aluminum depending on budget and performance.

- Shape and size: Flat, rectangular, or round depending on installation.

- Thermal performance: Ability to dissipate heat and avoid overheating.

- Insulation and protection: Safety measures for indoor or outdoor environments.

- Standards compliance: IEC, UL, or local standards for quality assurance.

6. Installation Best Practices

Improper installation is a major cause of busbar failures. Customers often face issues such as loose connections, overheating, or electrical faults. Follow these practices for reliable installation:

- Ensure proper torque tightening of connections.

- Use corrosion-resistant coatings or plating (e.g., tin-plated copper).

- Maintain correct spacing to prevent arcing and short circuits.

- Follow manufacturer guidelines for bending and mounting.

- Conduct routine inspections to detect wear or damage early.

7. Common Problems and Solutions

Even with careful planning, busbar systems may face challenges. Here are common problems and troubleshooting tips:

- Overheating: Caused by loose connections or undersized busbars. Solution: Use correct sizing and periodic maintenance.

- Corrosion: Particularly in outdoor or marine environments. Solution: Apply protective coatings and use insulated busbars.

- Short circuits: Due to inadequate spacing. Solution: Follow IEC standards for clearance distances.

- Mechanical stress: From vibration or improper mounting. Solution: Use flexible busbars or vibration-resistant supports.

8. Future of Busbar Technology

The role of busbars is expanding with the growth of renewable energy, electric mobility, and high-density data centers. Innovations such as laminated busbars, 3D-printed conductors, and eco-friendly insulating materials are shaping the future of power distribution systems.

9. How to Choose the Right Busbar Supplier

When selecting a busbar supplier, consider the following:

- Experience in your industry (renewable, industrial, commercial, etc.)

- Compliance with international standards

- Customization capabilities

- After-sales support and technical assistance

- Competitive pricing without compromising quality

Conclusion

A well-designed and properly installed busbar system is critical for efficient, safe, and long-lasting electrical distribution. Whether for residential, commercial, industrial, or renewable energy applications, understanding the fundamentals of busbar systems empowers engineers, contractors, and project managers to make informed decisions that enhance system reliability and reduce costs.