Troubleshooting Electrical Issues Caused by Copper Terminals: A Practical Maintenance Guide

Copper terminals are widely used in electrical systems because of their excellent conductivity, mechanical strength, and reliability. However, even the best copper terminals can fail if they are improperly installed, exposed to harsh environments, or not maintained correctly. When problems occur, they can lead to overheating, power loss, equipment failure, or even fire hazards. This in-depth guide provides a complete troubleshooting framework for identifying, diagnosing, and solving issues caused by copper terminals in residential, commercial, and industrial applications.

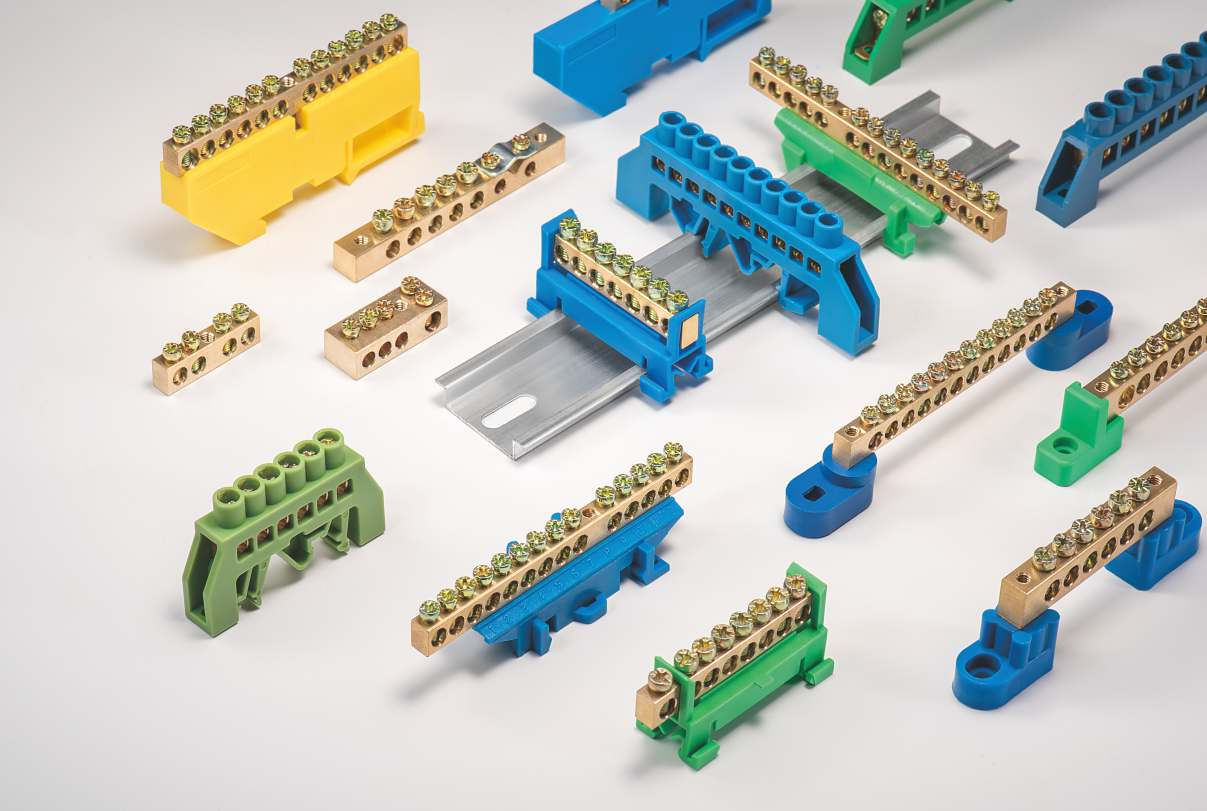

1. Introduction to Copper Terminals

Copper terminals, also known as copper lugs or copper connectors, are mechanical devices designed to securely connect wires or cables to electrical equipment. They are crucial in ensuring safe and reliable current flow in power distribution, control panels, renewable energy systems, and heavy machinery. While copper offers superior electrical properties, terminal failures are not uncommon. Understanding the root causes of these issues is the first step toward effective troubleshooting.

2. Why Copper Terminals Fail

Although copper itself is durable, various external and operational factors can cause terminal failure. The most common causes include:

- Loose Connections: Improper crimping, insufficient tightening torque, or vibration can loosen terminals over time.

- Corrosion: Exposure to moisture, salt, or chemicals can lead to oxidation and corrosion of copper surfaces.

- Overheating: High current loads or poor conductivity increase resistance, which generates excessive heat.

- Mechanical Stress: Frequent bending, pulling, or cable movement can weaken connections.

- Poor Quality Terminals: Using non-standard or low-quality copper terminals can compromise reliability.

3. Symptoms of Failing Copper Terminals

Early detection of terminal problems is essential for preventing major failures. Common warning signs include:

- Discoloration or black marks around the terminal (indicating overheating).

- Unusual smell (burnt insulation caused by heat).

- Voltage drop across the terminal connection.

- Frequent tripping of breakers or protective devices.

- Visible corrosion, green deposits, or rust on the copper surface.

- Loose or wobbly terminal connections when touched.

4. Step-by-Step Troubleshooting Process

A systematic troubleshooting approach helps maintenance personnel locate and resolve terminal issues quickly and safely. Below is a practical step-by-step method:

4.1 Visual Inspection

Begin by disconnecting power supply and inspecting terminals for visible signs of damage, corrosion, or overheating.

4.2 Thermal Scanning

Use an infrared thermometer or thermal imaging camera to detect hotspots. Overheated terminals will show higher temperature readings compared to surrounding connections.

4.3 Electrical Testing

Measure voltage drops across terminals using a multimeter. Excessive voltage drop indicates high resistance, which may be due to poor contact or corrosion.

4.4 Mechanical Testing

Gently tug or twist the cable at the terminal. If it moves easily, the connection may be loose and needs re-crimping or re-tightening.

4.5 Documentation and Root Cause Analysis

Record findings and analyze the root cause to prevent recurrence. For example, repeated corrosion may indicate inadequate protective coatings or environmental sealing.

5. Common Troubleshooting Scenarios

5.1 Overheating Terminals

If a copper terminal shows signs of overheating, verify the current rating of the cable and the terminal. Replace undersized terminals and ensure proper tightening torque is applied.

5.2 Corroded Terminals

Clean light corrosion using a wire brush and apply anti-oxidant compound. Severely corroded terminals should be replaced with new ones and sealed with protective covers.

5.3 Loose Terminals

Re-crimp the terminal with the appropriate crimping tool or retighten screws to the manufacturer’s torque specification. Always use compatible tools to avoid damage.

5.4 Broken or Cracked Terminals

Replace any physically damaged copper terminal immediately. Cracks compromise conductivity and can cause arcing.

6. Preventive Maintenance Practices

Proactive maintenance significantly reduces copper terminal failures. Recommended practices include:

- Periodic inspection and cleaning of terminals in electrical panels.

- Using thermal imaging during preventive maintenance to detect hotspots.

- Applying protective coatings for terminals exposed to corrosive environments.

- Following correct crimping and torque procedures during installation.

- Using high-quality copper terminals that comply with IEC/UL standards.

7. Tools and Equipment for Copper Terminal Maintenance

Effective troubleshooting requires the right tools. Essential equipment includes:

- Multimeter for voltage drop testing.

- Infrared thermometer or thermal camera for heat detection.

- Crimping tools with calibrated dies for secure connections.

- Wire brushes and cleaning solutions for corrosion removal.

- Protective gloves and safety goggles for operator safety.

8. Case Study: Industrial Panel Failures Due to Terminal Overheating

In a manufacturing facility, frequent tripping of circuit breakers was traced to overheated copper terminals. Investigation revealed that improper crimping techniques created high resistance connections. After replacing terminals with properly crimped, UL-approved copper lugs and applying correct torque, the problem was eliminated, restoring stable operations.

9. Safety Considerations

While troubleshooting copper terminals, always prioritize safety:

- De-energize circuits before inspection or repair.

- Wear insulated gloves and protective gear.

- Follow lockout-tagout (LOTO) procedures in industrial settings.

- Use only certified tools and replacement parts.

10. Conclusion

Copper terminals are essential for safe and efficient power distribution, but failures can cause serious electrical problems. By understanding failure modes, recognizing early warning signs, and applying systematic troubleshooting and preventive maintenance, technicians can ensure long-lasting and reliable electrical connections. High-quality copper terminals, proper installation, and regular inspection are the keys to preventing costly downtime and ensuring electrical safety.

Final Note: When in doubt, consult the terminal manufacturer’s installation guidelines and follow industry standards such as IEC, UL, and NEC to ensure compliance and reliability.