Copper Terminals vs. Aluminum Terminals: Which Is Better for Your Electrical System?

In every electrical project, one of the most critical decisions is selecting the right type of terminal. While copper terminals have traditionally dominated the market, aluminum terminals are increasingly being used due to cost considerations and advancements in material technology. But which one should you choose? This comprehensive guide explores the differences between copper and aluminum terminals in terms of conductivity, safety, durability, installation, and cost, so you can make an informed decision for your electrical system.

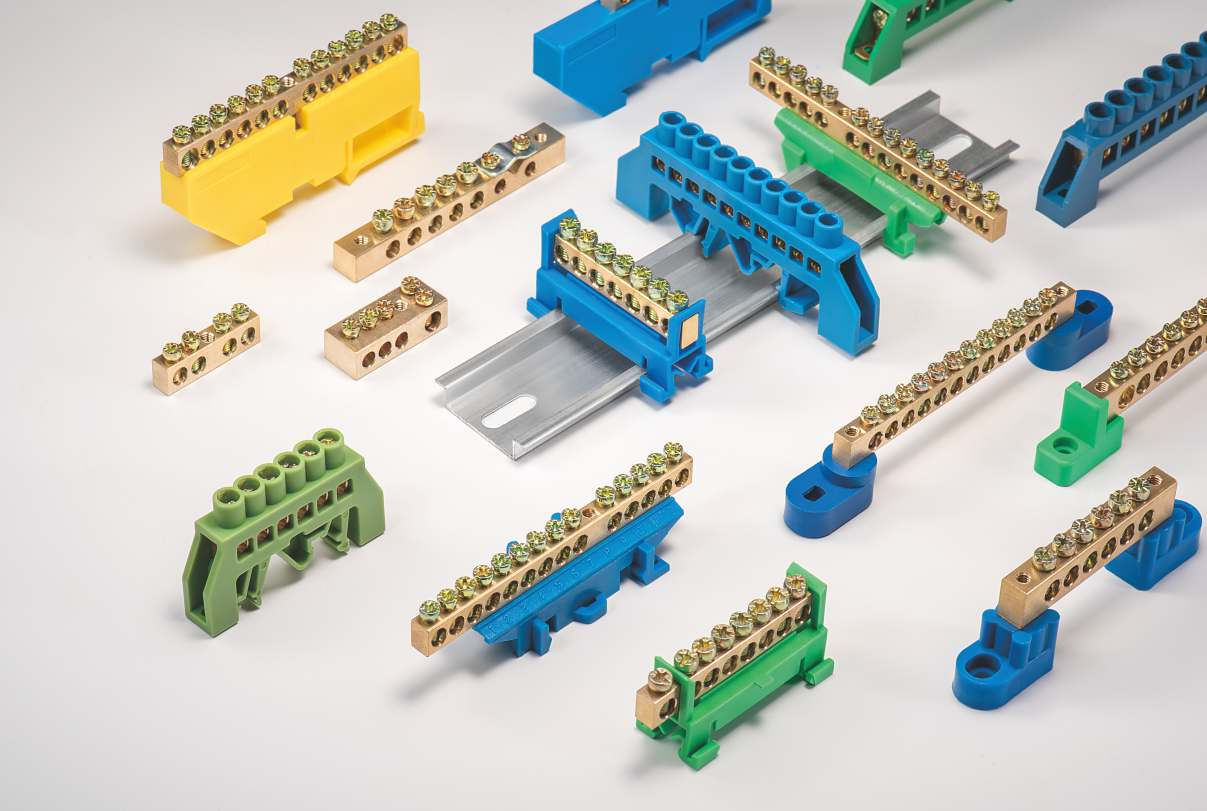

1. The Role of Electrical Terminals

Electrical terminals are the bridge between conductors and equipment. They ensure a secure, low-resistance connection for current flow. A poor terminal choice can lead to overheating, voltage drops, or system failure. Therefore, selecting the correct terminal material—copper or aluminum—directly impacts system reliability and safety.

2. Copper Terminals: An Overview

Copper has long been the preferred choice for terminals due to its excellent electrical and mechanical properties. Copper terminals are widely used in residential, commercial, industrial, and automotive applications. Advantages include:

- High conductivity: Copper offers about 40% higher conductivity than aluminum.

- Durability: Resistant to fatigue and mechanical stress.

- Corrosion resistance: Especially when tin-plated for harsh environments.

- Wide availability: A broad range of copper lugs, rings, and tubular terminals exist in global markets.

3. Aluminum Terminals: An Overview

Aluminum has gained popularity in power distribution and utility sectors. Its main attraction lies in its lower cost and lighter weight. Advantages include:

- Cost-effective: Aluminum terminals are typically 30–50% cheaper than copper.

- Lightweight: About one-third the weight of copper, beneficial in large-scale installations.

- Thermal expansion: New alloys and treatments reduce the risk of loosening connections under temperature variations.

- Sustainability: Aluminum is easier to recycle and often considered more eco-friendly.

4. Conductivity Comparison

One of the most significant differences between copper and aluminum is conductivity:

- Copper: Has a conductivity of 58 MS/m, making it the standard reference for electrical conductivity.

- Aluminum: About 35 MS/m, meaning larger cross-sectional areas are needed to carry the same current as copper.

This means aluminum terminals must often be bulkier to achieve the same performance as copper.

5. Durability and Mechanical Strength

Copper terminals are highly durable and less prone to fatigue, cracking, or loosening under vibration. Aluminum, while improved over the years, is still softer and more prone to mechanical stress. For applications with high vibration—such as automotive or marine—copper is typically preferred.

6. Corrosion Resistance

Both metals react differently in various environments:

- Copper: Naturally forms a protective oxide layer, but tin plating is often added for marine or outdoor use.

- Aluminum: Also forms an oxide layer, but galvanic corrosion can occur when aluminum is connected to copper conductors without proper treatment.

7. Safety Considerations

Safety is where copper often has the upper hand:

- Overheating risk: Improperly installed aluminum terminals are more prone to overheating.

- Connection stability: Copper provides more reliable long-term performance under load cycles.

- Fire hazard: Historical issues with aluminum wiring in the 1960s–70s highlight the risks if not properly managed.

8. Cost Comparison

Cost is the primary reason aluminum is considered. While copper prices are higher due to global demand and limited reserves, aluminum is abundant and affordable. For large projects, aluminum terminals can significantly reduce overall costs. However, cost savings must be balanced with safety and performance requirements.

9. Installation Practices

Installing copper and aluminum terminals requires different techniques:

- Copper Terminals: Easier to crimp and install; less sensitive to improper techniques.

- Aluminum Terminals: Require special anti-oxidation compounds and torque settings to prevent loosening and corrosion.

Installers must follow manufacturer instructions carefully when working with aluminum terminals.

10. Applications of Copper vs. Aluminum Terminals

- Residential wiring: Copper terminals are the standard due to safety and reliability.

- Industrial power distribution: Aluminum is often used for cost efficiency in large conductors.

- Automotive: Copper dominates due to vibration resistance and compact design.

- Renewable energy: Both are used, but copper is common in PV combiner boxes and inverters, while aluminum is favored for long-distance cable runs.

11. Standards and Certifications

International standards ensure both copper and aluminum terminals meet safety and performance requirements:

- IEC 61238: Governs compression and mechanical connectors for power cables.

- UL 486A-486B: Specifies wire connectors for copper and aluminum conductors.

- NEC (National Electrical Code): Provides installation guidelines in the U.S.

12. Future Trends

With rising copper prices, aluminum will continue to play a role, especially in large-scale utilities. Hybrid solutions, such as bimetallic terminals (copper-aluminum), are becoming popular to combine the benefits of both materials while minimizing drawbacks.

13. Choosing the Right Terminal for Your Project

The decision should be based on the following factors:

- Safety: If safety is paramount, copper is usually the better choice.

- Cost: For budget-sensitive projects, aluminum may be more viable.

- Application environment: Copper is preferred in corrosive, high-vibration, or critical applications.

- Standards compliance: Ensure whichever terminal you choose meets local and international standards.

Conclusion

Both copper terminals and aluminum terminals have their place in electrical systems. Copper excels in conductivity, reliability, and safety, while aluminum offers cost and weight advantages. In many cases, the best choice depends on the specific application, environment, and budget. For mission-critical systems where safety cannot be compromised, copper terminals remain the top recommendation. However, for large-scale installations where cost is a significant factor, aluminum—with proper installation techniques—can be a practical and safe alternative.