Design and Customization of PV Combiner Boxes: Tailoring Solutions for Different Solar Projects

Word Count Target: ~10,000 words

1. Introduction

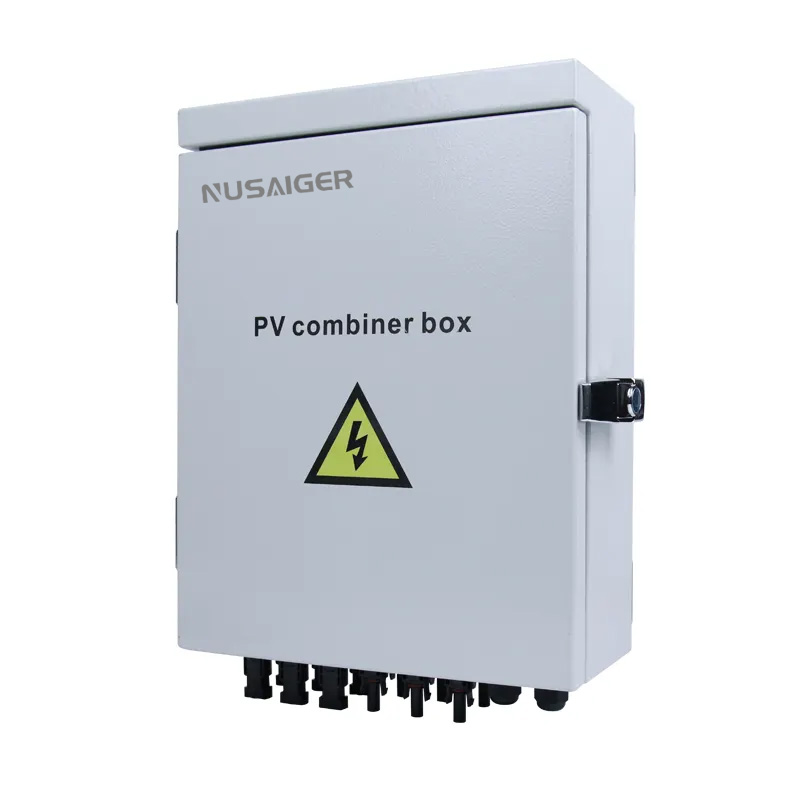

As the global solar industry evolves, one-size-fits-all solutions are no longer sufficient for many projects. PV combiner boxes—devices that aggregate power from multiple strings of solar panels—must be designed and customized according to the unique requirements of each installation.

From small residential rooftops to massive utility-scale solar farms, the design of a combiner box influences not only the efficiency of the system but also its safety, durability, and maintenance costs. This guide explores the principles of PV combiner box design and provides insights into customization strategies for different types of solar projects.

2. Core Design Principles of PV Combiner Boxes

Every PV combiner box, regardless of size or complexity, is designed around several key principles:

- Electrical Safety: Must include overcurrent protection, surge suppression, and safe disconnect options.

- Reliability: Components and enclosure materials must withstand environmental and electrical stress over 20+ years.

- Scalability: Designs should allow for system expansion without requiring full replacements.

- Accessibility: Engineers and technicians should be able to inspect and service components efficiently.

3. Key Design Components

3.1. Enclosure Materials

Enclosures protect sensitive components from dust, water, and UV radiation. Options include:

- Polycarbonate: Lightweight, cost-effective, and UV-resistant; suitable for residential and commercial systems.

- Stainless Steel: Corrosion-resistant and durable, ideal for coastal or industrial environments.

- Aluminum: Offers a balance between weight and durability, often used in utility-scale systems.

3.2. Busbars and Internal Wiring

Busbars must be sized for expected current loads with proper insulation. Copper is widely used for its conductivity, though aluminum is sometimes preferred for cost and weight considerations.

3.3. Protection Devices

- Fuses or circuit breakers sized according to string current ratings.

- Surge protection devices (SPDs) rated for local lightning risk.

- DC disconnect switches for safe isolation during maintenance.

3.4. Monitoring Modules

Smart combiner boxes integrate sensors and communication interfaces (RS485, Modbus, Ethernet) for real-time monitoring of voltage, current, and temperature at the string level.

4. Customization for Different Solar Projects

4.1. Residential Applications

In residential systems, simplicity and cost-effectiveness are priorities. Customized designs often focus on compact enclosures, IP65 weatherproofing, and a limited number of string inputs (2–6). Many residential boxes exclude monitoring to keep costs low.

4.2. Commercial Applications

Commercial rooftop and ground-mounted systems demand a balance of safety and performance. Customization may include:

- 6–12 string inputs.

- Basic monitoring for fault detection.

- Stainless steel enclosures for urban pollution resistance.

- Modular designs to fit limited rooftop space.

4.3. Utility-Scale Projects

Large solar farms require advanced customizations, including:

- 12–24 string inputs with high-voltage ratings (1000–1500 VDC).

- Integrated monitoring compatible with SCADA systems.

- High-grade SPDs with replaceable modules.

- Thermal management systems to prevent overheating in desert environments.

5. Smart Combiner Box Innovations

Customization is increasingly driven by digitalization. Modern smart combiner boxes include:

- IoT-enabled sensors for predictive maintenance.

- Real-time fault alerts sent to operators via cloud systems.

- Remote firmware updates for long-term adaptability.

6. Environmental Customization

Environmental conditions greatly influence combiner box design. Customization examples include:

- Desert regions: Dust-proofing, UV-resistant enclosures, and ventilation systems.

- Coastal regions: Marine-grade stainless steel to resist saltwater corrosion.

- Cold climates: Heating elements or insulation to prevent condensation and freezing.

7. Standards and Compliance

Customized combiner boxes must still comply with international standards such as:

- IEC 61439 (low-voltage switchgear assemblies).

- UL 1741 (North American PV equipment standard).

- NEC Article 690 (National Electrical Code for solar installations).

Compliance ensures both safety and project approval by local authorities.

8. Case Studies

Case Study 1: Residential Rooftop in Germany

A 10 kW rooftop system required a customized polycarbonate combiner box with 4 string inputs, SPD, and compact design. The customization reduced installation time and ensured compliance with local regulations.

Case Study 2: Commercial Rooftop in Singapore

Due to high humidity, stainless steel enclosures were used with IP66 sealing. Integrated monitoring allowed facility managers to quickly detect string-level faults.

Case Study 3: Utility Solar Farm in the Middle East

Combiner boxes were customized with desert-rated ventilation systems, IoT-enabled monitoring, and high-grade fuses. This design minimized overheating and ensured continuous operation under extreme temperatures.

9. Future Trends in Custom PV Combiner Boxes

The solar industry is rapidly advancing, and combiner box design will evolve accordingly:

- Integration with energy storage systems for hybrid solar-plus-battery setups.

- AI-driven predictive diagnostics for preventive maintenance.

- Modular plug-and-play combiner boxes to reduce onsite installation time.

- Eco-friendly enclosures made of recyclable materials.

10. Conclusion

PV combiner box design is not a one-size-fits-all process. Customization ensures that each solar project achieves maximum efficiency, safety, and longevity. Whether it is a compact box for residential rooftops, a rugged enclosure for commercial use, or a smart monitoring system for utility-scale projects, tailored designs align the combiner box with project-specific requirements.

By investing in the right design and customization, solar developers and operators can safeguard their assets, improve system reliability, and adapt to evolving industry trends.