How Environmental Conditions Impact PV Combiner Box Performance

A complete guide to environmental challenges in solar projects and how to protect PV combiner boxes for long-term reliability.

1. Introduction

Photovoltaic (PV) systems are often installed in diverse and extreme environmental conditions, from the deserts of the Middle East to coastal areas in Europe and high-altitude regions in South America.

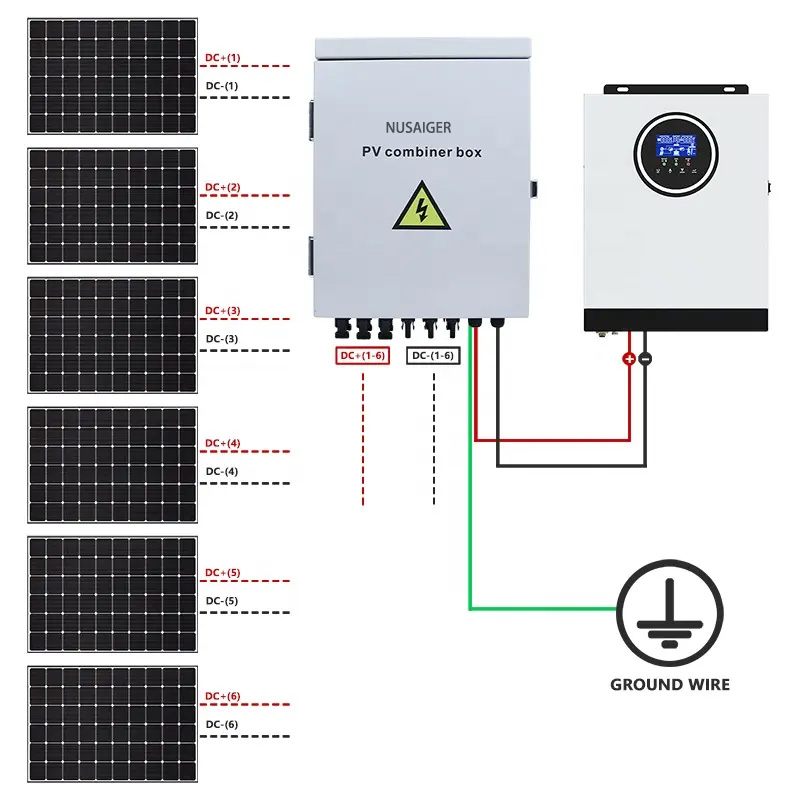

PV combiner boxes, which consolidate the output from multiple strings, must withstand these harsh conditions without compromising safety or performance.

In this article, we examine how environmental factors such as temperature, humidity, UV radiation, salt mist, and dust impact PV combiner box performance. We also outline strategies for selecting and maintaining combiner boxes for different climates.

2. Temperature and Thermal Stress

Temperature fluctuations are one of the biggest challenges for PV combiner boxes.

High ambient temperatures accelerate insulation aging, degrade plastic enclosures, and increase the risk of component failure.

- High-Temperature Regions (e.g., Middle East, Africa): Internal box temperature may exceed 70°C. This stresses fuses, circuit breakers, and surge protection devices (SPDs).

- Low-Temperature Regions (e.g., Canada, Scandinavia): Extreme cold makes plastics brittle and increases condensation risk when temperatures shift rapidly.

- Thermal Cycling: Daily temperature swings cause expansion and contraction, loosening electrical connections.

Solution: Use metal enclosures with high thermal tolerance, ensure ventilation, and select components rated for wide temperature ranges (-40°C to +85°C).

3. Humidity and Condensation

High humidity leads to condensation inside enclosures, promoting corrosion, short circuits, and insulation breakdown.

- Tropical Regions: Persistent humidity accelerates corrosion of terminals and busbars.

- Mountainous Areas: Rapid changes in temperature and altitude cause water condensation inside the combiner box.

Solution: Use anti-condensation heaters, breathable membranes, and conformal-coated PCBs to resist moisture damage.

4. Dust, Sand, and Airborne Particles

Dust and sand are especially problematic in desert regions, where they infiltrate enclosures and compromise connections.

- Dust: Causes overheating by covering components and obstructing ventilation.

- Sandstorms: Erode enclosure surfaces and damage seals, lowering IP protection rating.

Solution: Select enclosures with IP65+ rating, use dust-tight cable glands, and perform regular cleaning during O&M cycles.

5. Salt Mist and Corrosive Environments

Coastal and offshore solar installations face challenges from salt mist, which accelerates corrosion and degrades metal components.

- Corrosion of terminals and busbars.

- Accelerated aging of SPD and fuse holders.

- Risk of galvanic corrosion in mixed-metal connections.

Solution: Use stainless steel enclosures, marine-grade coatings, and salt-mist-certified combiner boxes (IEC 60068-2-52 tested).

6. UV Radiation

Prolonged exposure to ultraviolet (UV) light degrades plastic enclosures, making them brittle and prone to cracking.

Solution: Use UV-stabilized polycarbonate or powder-coated metal enclosures to ensure long-term durability.

7. Ingress Protection (IP) and Mechanical Protection (IK)

To handle diverse environmental factors, PV combiner boxes are tested for ingress protection (dust/water) and impact resistance.

- IP65/IP66: Minimum rating for outdoor solar installations.

- IK08/IK10: Ensures mechanical robustness against impact and vandalism.

8. Regional Case Studies

8.1 Desert Environments

In Saudi Arabia, utility-scale projects face sandstorms and 50°C temperatures. Stainless steel IP66 combiner boxes with SPD and anti-dust vents are the preferred solution.

8.2 Tropical Climates

In Southeast Asia, constant humidity leads to corrosion. Developers install dehumidifiers and select boxes with moisture-proof coatings.

8.3 Coastal Areas

In Spain’s coastal regions, salt mist requires marine-certified PV combiner boxes with reinforced gaskets and corrosion-resistant materials.

8.4 Cold Regions

In Canada, boxes are designed with heaters and insulation to prevent condensation and frost damage.

9. Best Practices for Combiner Box Selection by Climate

- Desert: High IP rating, UV-resistant enclosures, anti-dust design.

- Tropical: Anti-condensation systems, corrosion-resistant terminals.

- Coastal: Marine-grade stainless steel, salt-mist certification.

- Cold: Low-temperature-rated plastics, heaters, anti-frost vents.

10. Maintenance and Monitoring

Even with robust designs, environmental exposure requires periodic maintenance:

- Visual inspection for corrosion and cracks.

- Infrared thermography to detect hot spots.

- Periodic SPD and fuse replacement.

- Cleaning to remove dust, salt, or biological growth.

11. Conclusion

Environmental conditions have a significant impact on PV combiner box performance.

By understanding local challenges and selecting the right enclosure materials, certifications, and maintenance practices, project developers can ensure long-term reliability, reduce failures, and maximize solar plant ROI.