Troubleshooting Common PV Combiner Box Issues

A practical guide for solar operators and technicians to identify and solve common combiner box failures.

1. Introduction

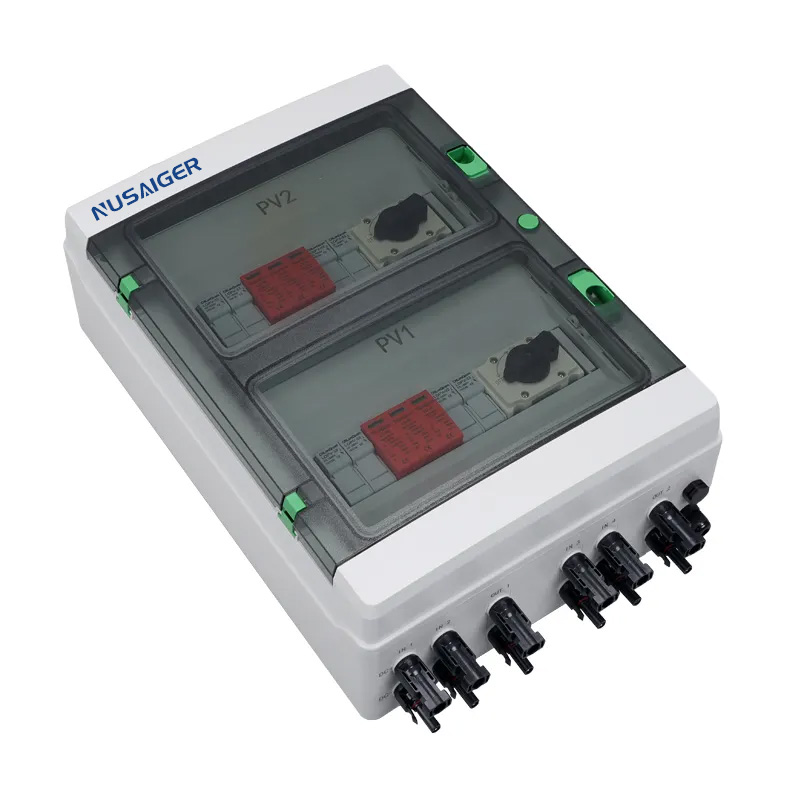

PV combiner boxes are critical junction points in solar installations. While they are designed for durability and safety,

environmental exposure, electrical stress, and installation errors can lead to failures.

Quick troubleshooting is essential to minimize downtime and energy loss.

In this article, we break down common issues faced in PV combiner boxes, diagnostic methods,

and effective solutions, along with preventive measures to avoid repeat failures.

2. Common PV Combiner Box Issues

- Blown fuses.

- Surge protection device (SPD) failure.

- Loose or corroded connections.

- Overheating and hot spots.

- Moisture ingress and condensation.

- Wiring errors or polarity reversal.

- Communication faults in smart combiner boxes.

3. Troubleshooting Blown Fuses

Fuses protect the system by breaking the circuit in case of overcurrent. Frequent fuse blowing may indicate deeper issues.

Possible Causes

- Short circuit in a PV string.

- Overcurrent due to mismatched string design.

- Loose terminal connections causing overheating.

Diagnostic Steps

- Visually inspect fuses for physical damage.

- Measure current of each string using a clamp meter.

- Check for ground faults or insulation breakdown.

Solutions

- Replace blown fuse with correct rating.

- Tighten loose connections.

- Address short circuits before energizing.

4. SPD (Surge Protection Device) Failures

SPDs protect against voltage surges caused by lightning or grid fluctuations.

A failed SPD leaves the system vulnerable.

Symptoms

- SPD indicator window turns red (end-of-life).

- Frequent tripping or alarms in monitoring system.

Solutions

- Replace failed SPD modules immediately.

- Ensure correct grounding and bonding.

- Consider higher-capacity SPDs for lightning-prone regions.

5. Loose or Corroded Connections

Loose or corroded connections lead to increased resistance, overheating, and power loss.

Symptoms

- Burn marks or discoloration around terminals.

- Inconsistent string performance.

Solutions

- Tighten connections to manufacturer torque specifications.

- Replace corroded connectors with tinned copper or stainless steel types.

- Apply anti-oxidation paste where necessary.

6. Overheating and Hot Spots

Overheating inside the combiner box can damage fuses, SPDs, and even melt insulation.

Possible Causes

- Excessive current load beyond design.

- Poor ventilation or high ambient temperatures.

- Loose connections causing localized heating.

Solutions

- Perform infrared thermography during inspections.

- Ensure adequate derating of components.

- Improve cooling and ventilation design.

7. Moisture Ingress and Condensation

Water ingress is a common failure mode in humid or coastal environments.

Symptoms

- Visible condensation inside the enclosure.

- Corrosion on busbars and terminals.

Solutions

- Use enclosures with IP65+ protection.

- Install anti-condensation heaters or breather valves.

- Inspect seals and gaskets regularly.

8. Wiring Errors and Polarity Reversal

Incorrect wiring during installation can cause immediate failures or long-term degradation.

Solutions

- Verify wiring with a multimeter before energizing.

- Label strings clearly for future maintenance.

- Use color-coded cables to avoid polarity mistakes.

9. Communication Errors in Smart Combiner Boxes

In IoT-enabled combiner boxes, communication faults can prevent accurate monitoring.

Causes

- Loose RS485 or Ethernet connections.

- Faulty communication modules.

- Software/firmware mismatch with SCADA systems.

Solutions

- Check and secure data cables.

- Restart communication modules or update firmware.

- Test connectivity with diagnostic tools.

10. Preventive Maintenance

Preventive maintenance helps avoid repeat issues and prolong system lifespan.

- Perform thermal imaging twice a year.

- Inspect seals, gaskets, and cable glands for leaks.

- Replace SPDs and fuses proactively based on service life.

- Log all faults in O&M software for trend analysis.

11. Case Studies

Utility Solar in Australia

Frequent fuse failures were traced to loose torque settings. A torque-wrench policy reduced failures by 70%.

Coastal Solar Plant in Brazil

SPD degradation due to salt mist was solved with marine-grade enclosures and sealed connectors.

Commercial Rooftop in USA

Communication loss in smart boxes was resolved by upgrading firmware and improving grounding design.

12. Conclusion

PV combiner box issues are common but manageable with proper troubleshooting and preventive maintenance.

By following structured diagnostic steps and implementing corrective actions, solar operators can minimize downtime,

protect equipment, and maximize energy yield.

A proactive approach ensures long-term system reliability and reduces operational costs.