Future Trends in PV Combiner Box Technology: AI, IoT, and Beyond

As the global energy landscape rapidly shifts toward renewable sources, photovoltaic (PV) systems have become essential for sustainable power generation. Among PV system components, the combiner box—once a simple electrical junction—now transforms into an intelligent device leveraging cutting-edge technologies. Innovations such as Artificial Intelligence (AI), the Internet of Things (IoT), advanced sensor arrays, and smart communication protocols are reshaping PV combiner boxes into critical nodes that enhance solar system performance, reliability, and maintainability.

1. The Evolution of PV Combiner Boxes: From Passive to Intelligent Devices

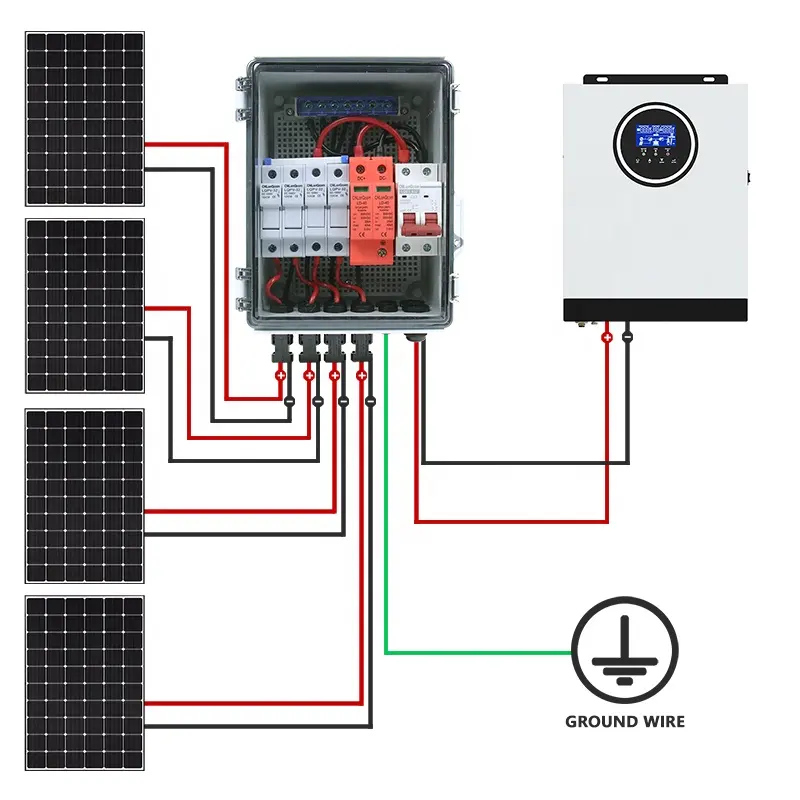

Traditionally, PV combiner boxes aggregated currents from multiple solar panel strings into fewer conductors routed to inverters or charge controllers. Equipped with fuses, breakers, and sometimes surge protection, their main role was safety and wiring simplification. However, modern solar installations demand higher efficiency, remote monitoring, and fault detection, pushing combiner boxes to evolve with embedded microcontrollers, digital sensors, and communication modules.

This evolution enables real-time monitoring of parameters like voltage, current, temperature, and fault detection down to string or even module levels. Integration with Supervisory Control and Data Acquisition (SCADA) systems allows centralized control, data analysis, and rapid fault response.

2. IoT Integration: Empowering Real-Time Monitoring and Control

IoT integration turns PV combiner boxes into smart nodes connected via wireless or wired networks to cloud platforms. This connectivity facilitates real-time transmission of system data, enabling stakeholders to remotely monitor performance, detect issues, and optimize operation.

- Predictive Maintenance: Continuous sensor data feeds machine learning algorithms that forecast failures before they occur, scheduling proactive maintenance.

- Performance Optimization: Detailed analytics identify underperforming strings or shading effects, allowing timely interventions.

- Energy Management: Dynamic monitoring supports load balancing, battery storage integration, and demand response strategies.

- Cost Savings: Remote diagnostics minimize costly onsite inspections and downtime.

3. Artificial Intelligence: Revolutionizing Diagnostics and Optimization

AI leverages large datasets from combiner box sensors to identify subtle fault signatures and operational inefficiencies beyond human capability. Deep learning models detect partial shading, module degradation, arc faults, and connection issues early. Automated diagnostics accelerate troubleshooting and facilitate automatic system adjustments for maximum yield.

By continuously learning from operating data, AI models improve over time, adapting to new failure modes and environmental conditions, thereby enhancing solar plant resilience and lifetime performance.

4. Advanced Sensor Technologies for Comprehensive Monitoring

Modern PV combiner boxes integrate a variety of sensors beyond electrical measurements:

- Infrared (IR) Sensors: Detect hot spots, preventing fire risks.

- Environmental Sensors: Track ambient temperature, humidity, and irradiance to contextualize performance data.

- Arc Fault Detectors: Identify hazardous electrical arcs that threaten system safety.

- Vibration and Shock Sensors: Monitor mechanical stresses impacting enclosure integrity.

These multi-dimensional sensor inputs create a holistic view of system health, enabling sophisticated control and early warnings.

5. Robust Communication Protocols and Cybersecurity

PV combiner boxes are increasingly connected via advanced protocols like MQTT, OPC UA, and emerging 5G cellular networks, facilitating fast and reliable data exchange. However, connectivity introduces cybersecurity challenges. Future combiner boxes employ:

- End-to-end data encryption

- Secure boot and firmware updates

- Device authentication and access control

- Intrusion detection systems

These measures safeguard against hacking, data theft, and malicious attacks, ensuring solar infrastructure integrity as part of critical energy grids.

6. Modular and Adaptive Hardware Designs

Next-generation combiner boxes are designed modularly for easy scalability and customization. Plug-and-play modules allow configuring input channels, protection devices, and monitoring features per project requirements. Adaptive architectures enable seamless integration with hybrid renewable systems combining solar, storage, and wind power.

Modularity simplifies installation, reduces maintenance time, and future-proofs solar plants for technology upgrades.

7. Energy Management and Smart Grid Integration

Smart PV combiner boxes support two-way communication with utility grids and energy management systems. They enable:

- Dynamic power flow control

- Demand response participation

- Grid stability support via voltage and frequency regulation

- Renewable energy forecasting and load balancing

This grid interaction facilitates higher renewable penetration and resilience in modern energy systems.

8. Sustainability and Eco-Friendly Materials

Sustainability extends beyond energy generation to the components themselves. Future combiner boxes prioritize:

- Use of recyclable and low-impact materials

- Manufacturing processes minimizing waste and emissions

- Energy-efficient electronics reducing operational carbon footprint

- Designs enabling easy end-of-life disassembly and recycling

These approaches align PV component production with global environmental goals.

9. Compliance with Evolving Standards and Regulations

Rapid technological advances necessitate compliance with updated standards addressing safety, interoperability, and environmental impact. Standards bodies such as IEC, UL, and IEEE continuously refine requirements for:

- Electrical safety and surge protection

- Communication protocols and cybersecurity

- Environmental durability and weatherproofing

- Energy efficiency and performance

Adhering to these standards ensures market acceptance and long-term system reliability.

10. Challenges and Future Opportunities

While intelligent PV combiner boxes offer transformative benefits, challenges remain:

- Cost: Advanced features increase upfront costs, requiring careful cost-benefit analysis.

- Complexity: Integrating diverse sensors and communication modules demands robust design and quality control.

- Interoperability: Ensuring compatibility across multi-vendor systems and protocols is critical.

- Cybersecurity: Constantly evolving threats require ongoing vigilance and updates.

Despite these hurdles, ongoing innovation promises smarter, more resilient solar infrastructure. Research into AI-driven autonomous control, edge computing, and blockchain-enabled energy trading could further revolutionize PV combiner box functionality.

Conclusion

The future of PV combiner box technology is bright and dynamic, shaped by AI, IoT, modular hardware, and sustainability trends. These intelligent devices will play a pivotal role in maximizing solar power generation, enhancing grid integration, and ensuring safe, reliable operation. Stakeholders embracing these innovations stand to benefit from improved energy yields, reduced operational costs, and stronger alignment with global clean energy objectives.

As the solar industry continues to evolve, keeping pace with these technology trends will be essential for manufacturers, installers, and system operators aiming to build the next generation of smart, sustainable energy solutions.