Top 10 Benefits of Using Busbars in Industrial Electrical Systems

Introduction

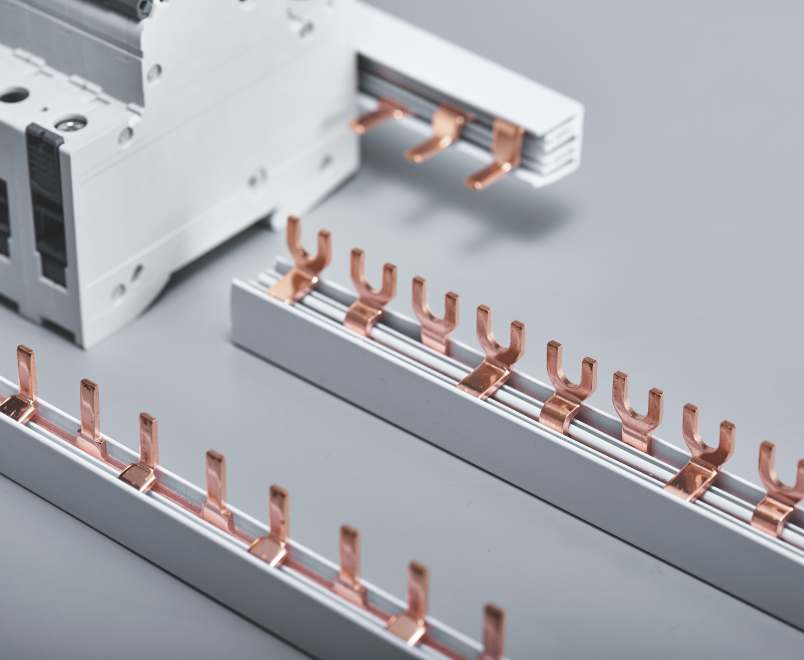

In the ever-evolving landscape of industrial electrical engineering, the busbar stands as a cornerstone component that ensures safe and efficient distribution of power. As energy needs grow and infrastructures become more complex, industries must rely on advanced and adaptable power distribution solutions. Busbars not only meet these needs but exceed traditional cable systems in multiple ways. In this article, we will explore the top 10 benefits of using busbars in industrial settings and why they are becoming the standard in electrical design.

1. Enhanced Space Efficiency

Busbars are compact and highly efficient in terms of space utilization. Compared to traditional cabling systems, busbars allow for a more streamlined and organized electrical setup. Their rigid design and ability to carry large currents through a narrow physical space make them ideal for space-constrained environments like industrial switchgear and control panels.

2. Superior Electrical Performance

One of the most significant advantages of using busbars is their superior electrical conductivity and low impedance. Typically made from copper or aluminum, busbars can transmit electricity with minimal energy loss. This leads to enhanced performance, reduced energy costs, and better overall system efficiency.

3. Reduced Installation Time

Installing a busbar system is considerably quicker than setting up a traditional cable-based system. Pre-engineered components, modular designs, and fewer connection points all contribute to faster and more straightforward installation. This results in reduced labor costs and shorter project timelines.

4. Improved Safety and Reduced Risk

Busbars are designed to be safe. They offer high levels of protection against short circuits, overloads, and electrical fires. Many systems come with protective coatings or insulation that prevent accidental contact, arc flashes, and other electrical hazards. Additionally, their rigid structure reduces the risk of cable entanglement or degradation over time.

5. Easier Maintenance and Inspection

Due to their open and structured layout, busbars are far easier to inspect and maintain than cable systems. Technicians can quickly identify faults, perform thermal imaging, or replace defective sections without disturbing the rest of the system. This minimizes downtime and improves overall reliability.

6. Scalability for Future Expansion

Busbar systems are modular, allowing easy integration of additional circuits or extensions. As industries grow and electrical demands increase, busbars provide a flexible and scalable solution that can evolve with the facility’s requirements without the need for a complete redesign.

7. Better Heat Dissipation

Heat management is critical in industrial electrical environments. Busbars have a flat, exposed surface area that promotes better heat dissipation compared to bundled cables. This helps prevent overheating, extends the lifespan of components, and ensures stable performance under heavy loads.

8. Cleaner Aesthetic and Design

While aesthetics may not be the primary concern in industrial applications, the neat and organized appearance of busbar systems can make maintenance safer and environments more compliant with industry standards. A clean system is easier to audit, inspect, and trust.

9. Environmental Benefits

Busbars can be more environmentally friendly than cables. They require less insulation, fewer accessories, and are often manufactured with recyclable materials. This reduces material waste during both manufacturing and end-of-life disposal.

10. Cost Savings Over Time

Although the initial cost of a busbar system may be higher than that of traditional cables, the long-term savings are substantial. Reduced maintenance, energy efficiency, faster installation, and minimal downtime all contribute to significant cost reductions over the system’s lifetime.

Conclusion

Industrial facilities today require smart, durable, and scalable solutions for electrical distribution. Busbars deliver on all fronts, offering unmatched performance, safety, and long-term reliability. By integrating busbar systems, industries can position themselves for future growth while optimizing energy use and reducing operational costs.