Busbar Applications in Power Distribution Systems

Busbars are integral to electrical infrastructure, enabling safe, efficient, and reliable distribution of power across various sectors. Their adaptability, high current-carrying capacity, and structural simplicity make them the backbone of many energy systems. This article provides a deep dive into real-world busbar applications, spanning traditional utility networks to cutting-edge renewable energy platforms.

1. Overview: Why Busbars Are Crucial

Busbars simplify complex wiring systems, reduce system losses, and facilitate ease of maintenance and future expansion. Whether you’re building a high-voltage transmission grid or a compact data center, busbars play a vital role in modern electrical engineering.

2. Applications in Power Generation Facilities

In power generation stations — thermal, hydro, nuclear, or renewable — busbars are used to collect power from multiple generators and distribute it to step-up transformers.

- Main generator bus: Collects output from turbines

- Exciter bus: Provides excitation current to the generator field

- Auxiliary bus: Powers plant operations like pumps, compressors, lighting

3. Busbars in Electrical Substations

Substations are the nerve centers of power transmission systems. Busbars are used to route power through different feeders and transformers:

- Single bus configuration: Simplest, used in low-voltage systems

- Main and transfer bus: Enables switching without interrupting power

- Ring bus and breaker-and-a-half: Applied in critical or high-reliability systems

Busbars in substations allow for flexible load switching, redundancy, and protection coordination.

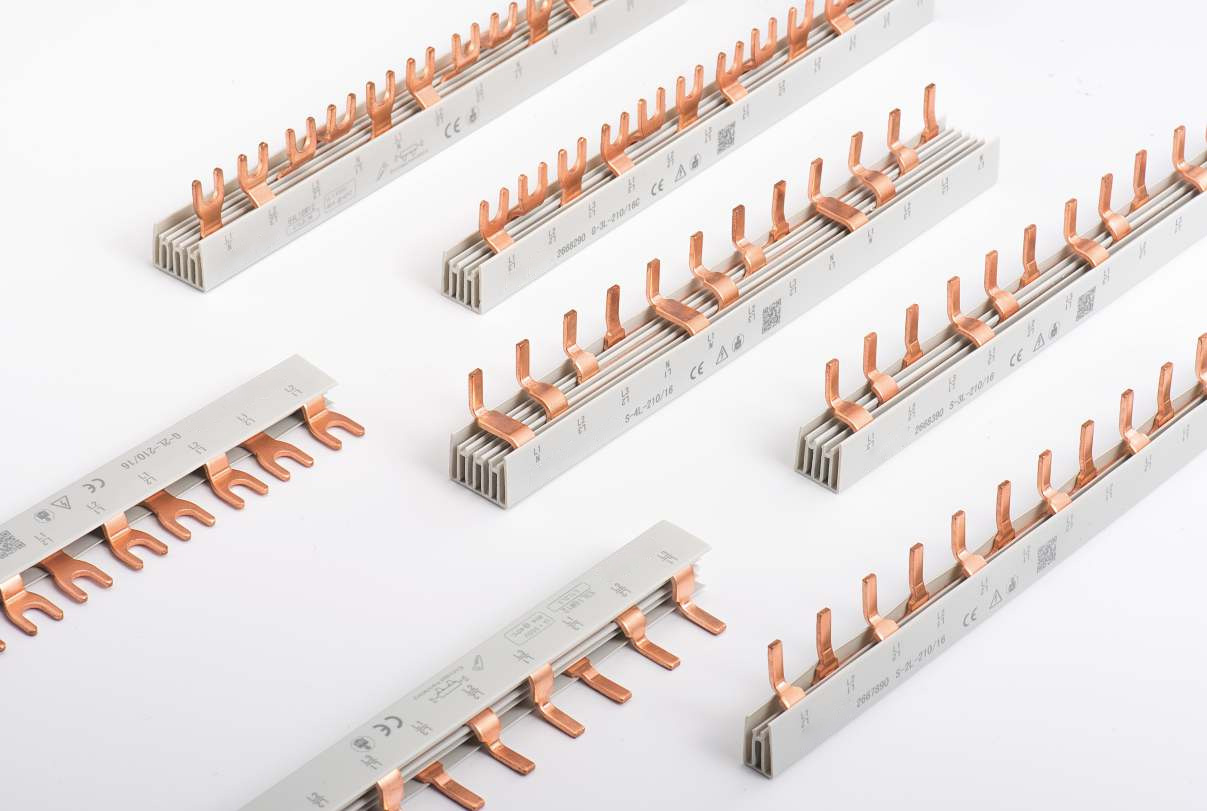

4. Industrial and Commercial Electrical Panels

Busbars offer numerous benefits in commercial buildings and industrial facilities:

- Enable modular design and future expansion

- Handle large currents with minimal voltage drop

- Reduce wiring errors and system complexity

They are widely used in:

- Motor control centers (MCCs)

- Automation and PLC cabinets

- HVAC distribution panels

- Lighting control panels

5. Data Centers and Server Infrastructure

Modern data centers rely on reliable and scalable power systems. Busways (a type of insulated busbar system) are commonly used due to their modularity and current handling capacity. Key benefits:

- Quick reconfiguration of server racks

- Reduced downtime

- Cleaner, neater installations compared to cables

6. Renewable Energy Systems

Busbars are critical in solar and wind energy systems:

- Photovoltaic Combiner Boxes: Aggregate outputs from multiple PV strings to a single DC busbar

- Inverter input/output: Busbars distribute DC or AC current

- Battery storage systems: Copper or aluminum busbars connect battery modules and inverters

In these environments, lightweight and corrosion-resistant busbars (often insulated or tin-plated) are preferred.

7. Electric Vehicles and Charging Infrastructure

EV batteries and fast-charging stations rely heavily on laminated busbars for:

- High current handling

- Space-efficient routing

- Thermal control and EMI reduction

8. Railway and Transport Systems

Busbars power electric locomotives, train lighting, and onboard control systems. Flexible braided busbars are ideal for handling vibration and movement in these applications.

9. Marine and Offshore Applications

Ships, oil rigs, and offshore wind platforms use busbars to distribute power to propulsion systems, navigation, and life-support equipment. These environments demand corrosion-resistant and highly insulated busbar systems.

10. Building Electrical Distribution

In high-rise buildings, malls, and hospitals, vertical riser busbars carry power across floors. Their compact size and reduced fire risk compared to large cable bundles make them ideal.

11. Mining and Tunneling Equipment

Portable power systems in harsh underground environments use busbars in mobile substations and control gear. Often these are shielded or armored for durability.

12. Lighting Busbar Trunking Systems

Commercial lighting systems use specialized busbars with plug-in points for light fixtures. This modularity allows for easy reconfiguration and maintenance.

13. Temporary Power Systems

Events, exhibitions, and construction sites often use busbars for rapid deployment of temporary power. These mobile systems are compact, weatherproof, and easy to connect.

14. Advantages of Busbar-Based Systems Over Cable-Based Systems

- Lower installation time and cost

- Higher efficiency and lower losses

- Better cooling and current density

- Simpler layouts with cleaner routing

- Easy upgrades and future scalability

15. Common Configurations in Busbar Layout

Common electrical layouts include:

- Single busbar layout: Cost-effective but no redundancy

- Double busbar layout: Allows maintenance without interruption

- Ring bus layout: Adds resilience and fault isolation

- Mesh layout: Used in critical substations

16. Future Trends in Busbar Applications

- Integration of monitoring sensors (IoT-enabled busbars)

- High-temperature superconducting busbars (HTS)

- Environmentally friendly insulation materials

- AI-based load balancing and diagnostics via embedded sensors

17. Conclusion

From power plants to modern EV charging stations, busbars are essential for managing electrical distribution with reliability and efficiency. Understanding where and how to use them helps electrical professionals design systems that are safe, scalable, and cost-effective.