Busbar Basics: Types, Functions & Applications

Busbars form the backbone of modern electrical distribution systems. This guide provides a comprehensive 10,000-word reference covering everything from types, materials, design, installation, testing, maintenance, and troubleshooting of busbars across industrial, commercial, and renewable energy applications.

What is a Busbar?

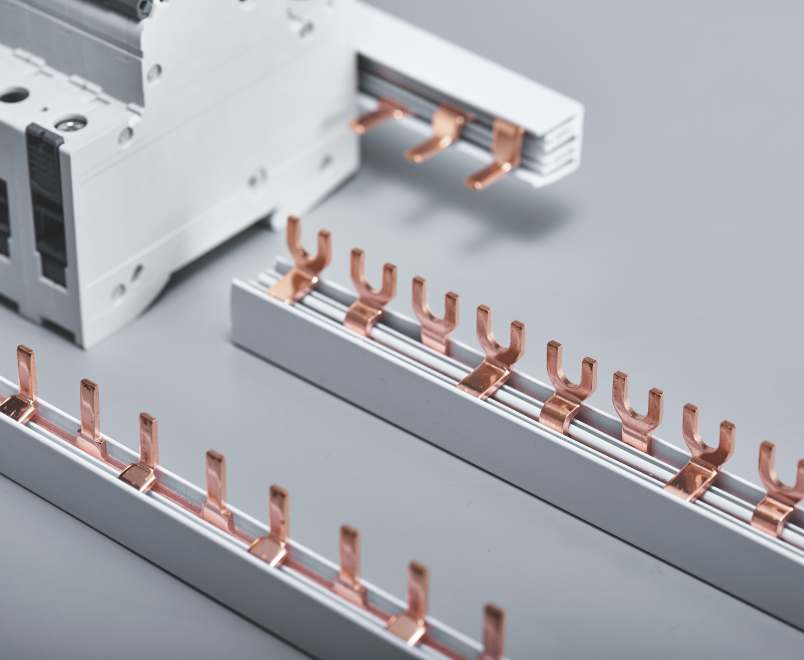

A busbar is a metallic strip or bar used for conducting electricity within electrical switchgear, distribution boards, substations, and busway systems. Typically made of copper or aluminum, busbars carry large currents efficiently between incoming feeders, transformers, circuit breakers, and outgoing circuits. They replace multiple cable runs with a single conductor, reducing resistive losses, simplifying connections, and providing a compact distribution solution.

Busbars are designed to handle high current loads while minimizing energy loss, voltage drop, and heat generation. They are essential components in medium- and low-voltage switchgear, UPS systems, data centers, industrial power distribution, and renewable energy plants.

History & Evolution of Busbars

The concept of busbars dates back to early power distribution in the 19th century when electrical engineers realized that multiple cable connections led to high losses and cumbersome installations. Early busbars were simple copper strips mounted on insulators. With the rise of industrialization, busbar systems evolved into compact, insulated assemblies, including aluminum options for lighter designs. Modern busbars are modular, segmented, and often enclosed to meet safety, reliability, and maintenance requirements.

Types of Busbars

Understanding busbar types is crucial for system designers and engineers. The main categories include:

- Solid Busbar: A flat, thick metallic strip, usually copper, providing high ampacity and stiffness. Ideal for compact switchgear where high currents are needed.

- Hollow/Tube Busbar: Tubular sections reduce weight without sacrificing mechanical strength. Commonly used in medium-voltage systems.

- Insulated Busbar: Busbars covered with PVC or polymer insulation for safety, preventing accidental contact, and allowing closer spacing.

- Segmented/Enclosed Busway: Prefabricated modular busbar assemblies in an enclosure, often with tap-off points for flexible system expansion.

- Flexible Busbar: Laminated or braided conductors used in applications with vibration, movement, or thermal expansion.

Materials & Conductivity

Copper and aluminum are the most common busbar materials:

- Copper: High conductivity, low resistance, excellent thermal performance, but heavier and costlier.

- Aluminum: Lightweight, cost-effective, lower conductivity — requires a larger cross-section.

Surface plating, such as tin, nickel, or silver, improves corrosion resistance and solderability in specific environments. Engineers must consider conductivity, cost, weight, mechanical strength, and environmental conditions when selecting materials.

Design Considerations

Proper busbar design ensures safety, efficiency, and reliability:

- Ampacity: Calculate maximum continuous current the busbar will carry.

- Short-circuit Rating: Must withstand prospective short-circuit currents without deformation.

- Voltage Drop: Keep within acceptable limits to maintain equipment performance.

- Thermal Expansion: Allow for expansion and contraction due to temperature changes.

- Mechanical Support: Design supports, brackets, and insulation to prevent sagging or vibration damage.

Engineering standards such as IEC 61439, IEEE 605, and UL 857 provide detailed guidance for busbar sizing, spacing, and testing.

Installation Guidelines

Installing busbars correctly is critical for electrical safety and performance:

- Ensure the power source is de-energized and proper lockout/tagout procedures are followed.

- Verify busbar dimensions, material, and type match the design.

- Use torque-calibrated tools for bolted connections to prevent overheating or loosening.

- Maintain proper spacing between phases and from grounded surfaces according to voltage rating.

- Check alignment and support to prevent sagging and vibration issues.

- Label each busbar and tap-off point clearly for maintenance and troubleshooting.

Maintenance & Testing

Regular maintenance ensures longevity and reliability:

- Visual inspection for corrosion, discoloration, or mechanical damage.

- Torque audits to ensure bolted connections remain secure.

- Infrared thermal imaging to detect hotspots under load.

- Micro-ohm resistance measurements to detect early signs of contact deterioration.

- Cleaning dust, debris, or oxidation from surfaces.

Preventive maintenance schedules should be established based on environment, load profile, and industry regulations.

Applications Across Industries

Busbars are widely used in:

- Industrial Facilities: Power distribution in plants, control centers, and heavy machinery.

- Commercial Buildings: Distribution panels, UPS systems, and energy management systems.

- Renewable Energy: PV inverters, wind turbine substations, and battery storage systems.

- Data Centers: Redundant, high-capacity power distribution for servers and networking equipment.

- Transportation: Railway electrification, electric buses, and ships requiring compact high-current distribution.

Safety & Standards

Follow international and local safety standards:

- IEC 61439 – Low-voltage switchgear and controlgear assemblies.

- IEEE 605 – Busbar trunking systems.

- UL 857 – Busways for commercial installations.

- ANSI/NEMA standards for clearances, insulation, and current ratings.

- Always wear PPE and use insulated tools during installation and maintenance.

Troubleshooting & Common Failures

Common busbar issues include:

- Overheating: Caused by loose connections, undersized busbars, or high-resistance contacts.

- Corrosion: Due to moisture ingress, chemical exposure, or improper plating.

- Vibration Damage: May loosen bolted connections or stress busbar supports.

- Mechanical Sag: Insufficient support leads to deformation, especially in long spans.

Preventative measures include proper installation, regular inspection, and using vibration-resistant fasteners or supports.

Frequently Asked Questions

Can aluminum busbars replace copper?

Yes, for many applications, but the cross-section must be larger to carry the same current due to lower conductivity. Mechanical connections require special torque considerations.

How often should busbars be inspected?

Visual and thermal inspections should be done annually, with torque audits every 12–24 months depending on load and vibration conditions.

What is the typical lifespan of a busbar?

With proper installation and maintenance, busbars can last 20–30 years in industrial or commercial applications.

Glossary of Terms

- Ampacity

- Maximum continuous current a busbar can carry without exceeding its temperature rating.

- Short-Circuit Withstand

- Ability to resist mechanical and thermal stresses during a fault condition.

- Voltage Drop

- Reduction in voltage along the busbar due to resistance.

- Insulation Class

- Classification of insulating material based on maximum operating temperature.

Conclusion

Busbars are critical components in modern electrical systems. Understanding types, materials, design, installation, maintenance, and troubleshooting ensures system reliability, efficiency, and safety. Engineers and electricians must follow standards, maintain inspection schedules, and apply best practices to maximize performance across industrial, commercial, and renewable energy applications.