Busbar Maintenance Guide: Best Practices for Long-Term Reliability

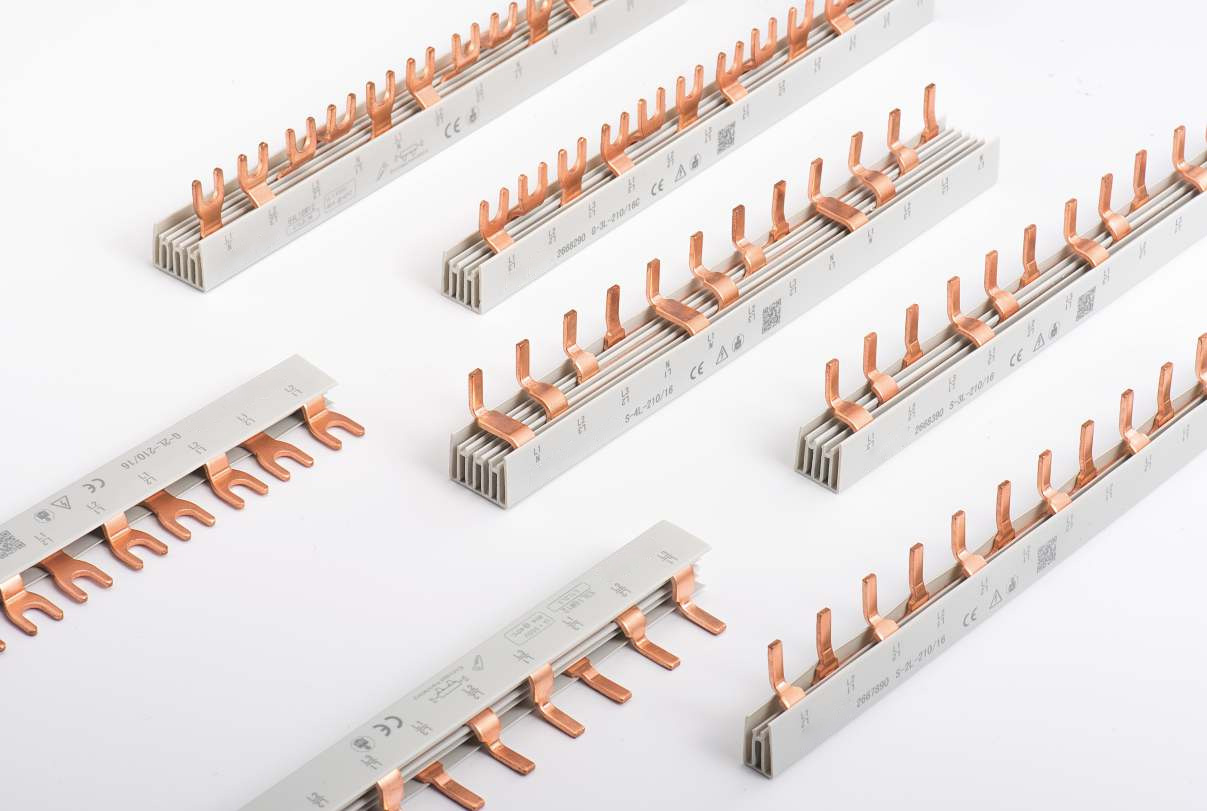

Busbars are critical electrical components used in distribution systems to carry large currents efficiently. Like all electrical components, they are subject to wear, corrosion, and potential failure without proper maintenance. This comprehensive guide explores the best practices for maintaining busbar systems to ensure long-term performance, safety, and cost-effectiveness.

1. Why Busbar Maintenance Matters

Electrical busbars form the backbone of many industrial and commercial power distribution systems. Over time, environmental exposure, load changes, and installation inconsistencies can impact their integrity. Regular maintenance helps:

- Prevent system failures and power outages

- Reduce operational costs through early fault detection

- Enhance safety for operators and technicians

- Prolong the service life of the electrical system

2. Common Busbar Maintenance Challenges

Before diving into preventive measures, it’s crucial to understand common issues that plague busbar systems:

- Oxidation: Exposure to air and moisture causes aluminum and copper busbars to oxidize, increasing resistance.

- Loose connections: Thermal cycling and vibration can loosen terminals and create hot spots.

- Insulation degradation: Age, UV exposure, and contamination can degrade insulation material.

- Overheating: Excessive current or poor ventilation may result in localized heating and thermal damage.

3. Busbar Inspection Schedule

Establishing a regular inspection routine is the first step in effective maintenance. Below is a recommended schedule:

- Monthly: Visual inspection for discoloration, corrosion, or physical damage

- Quarterly: Thermal imaging to detect hot spots or uneven current distribution

- Annually: Mechanical torque check of all fasteners and connectors

- Every 3–5 years: Complete shutdown and physical testing (e.g., insulation resistance)

4. Visual and Physical Inspection Techniques

Here’s how to conduct a thorough busbar inspection:

- Clean the surface: Use an approved contact cleaner to remove dirt, dust, or grease.

- Check alignment: Ensure busbars are properly spaced to avoid arcing.

- Inspect joints: Examine all bolted connections for tightness and signs of overheating.

- Check for wear: Look for signs of fatigue or cracking in insulation and support materials.

5. Infrared Thermographic Inspection

Infrared imaging is a non-invasive diagnostic tool used to identify thermal anomalies in electrical systems. Key benefits include:

- Detection of hot spots due to loose or corroded connections

- Identification of uneven load distribution

- Prevention of catastrophic failures with early diagnosis

It is recommended to hire certified thermographers to perform the analysis and interpret the results professionally.

6. Cleaning and Lubrication

Periodic cleaning helps maintain electrical contact and prevent tracking. Use non-abrasive cleaning cloths and follow manufacturer guidelines for conductive grease application (typically on sliding or bolted contacts).

7. Retightening and Torque Verification

All bolted connections should be re-torqued to the manufacturer’s specifications during each annual inspection. Improper torque can result in arcing or complete connection failure.

8. Testing Insulation Resistance

Insulation resistance testing should be conducted using a megohmmeter (commonly known as a “megger”). The resistance value should not fall below 1 MΩ per 1,000V of operation. A sudden drop in resistance signals insulation breakdown or moisture ingress.

9. Record Keeping and Data Logging

Maintenance logs are essential for trend analysis and decision-making. Include date of inspection, test results, anomalies observed, and corrective actions taken. Digital tools can help streamline this process and support predictive maintenance strategies.

10. When to Replace a Busbar System

Some signs that a busbar or component needs replacement include:

- Severe corrosion or pitting of the conductor

- Repeated insulation failure despite maintenance

- Unmanageable hot spots even after retightening

- Non-compliance with updated electrical standards

11. Best Practices for Long-Term Reliability

- Use high-quality busbar materials (e.g., tin-plated copper)

- Follow correct installation procedures

- Ensure adequate ventilation around busbars