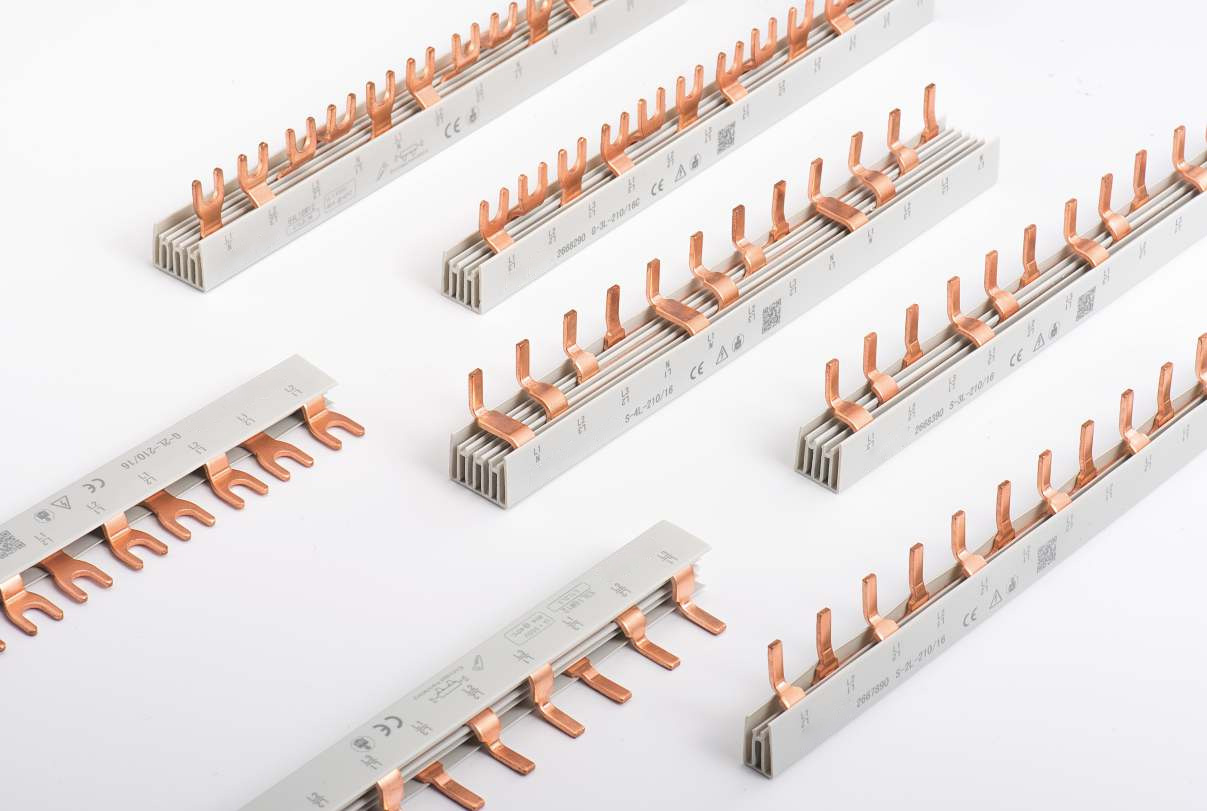

Busbar Maintenance Guide: Inspection, Troubleshooting, and Lifetime Extension

A busbar system is designed for long-term reliability, but like all electrical components, it requires proper maintenance. Ignoring busbar inspection and upkeep can lead to overheating, downtime, and costly repairs. This article explains how to maintain busbars effectively, troubleshoot common problems, and extend their operational life.

1. Why Busbar Maintenance Is Essential

Busbars operate under high current and mechanical stress. Over time, thermal cycling, vibration, dust accumulation, and corrosion degrade performance. Regular maintenance ensures:

- Safe and reliable power distribution

- Early detection of weak points

- Reduced downtime and repair costs

- Extended system lifespan

2. Recommended Maintenance Schedule

- Monthly: Visual inspection for dust, dirt, or loose fasteners

- Quarterly: Check connection torque, inspect insulation

- Annually: Perform thermal imaging, insulation resistance testing

- Every 3–5 years: Deep inspection with partial disassembly and surface cleaning

3. Key Inspection Points

During routine checks, pay attention to the following:

- Connections: Ensure bolts are tightened to the correct torque

- Surface condition: Look for oxidation, discoloration, or corrosion

- Insulation: Check for cracks, burns, or peeling coatings

- Mechanical support: Verify that busbar supports are intact and free from vibrations

- Ventilation: Ensure proper airflow around the busbar system

4. Common Problems and Troubleshooting

4.1 Overheating

Cause: Loose connections, undersized busbars, poor ventilation

Solution: Tighten joints, upgrade busbar size, improve cooling

4.2 Corrosion

Cause: Moisture, chemical exposure, or lack of protective coating

Solution: Apply plating (tin or silver), use anti-corrosion compounds, control humidity

4.3 Electrical Arcing

Cause: Insufficient clearance between phases, damaged insulation

Solution: Re-insulate busbars, increase spacing, install barriers

4.4 Mechanical Deformation

Cause: Thermal expansion, vibration, or improper mounting

Solution: Add flexible joints, reinforce supports, allow for expansion gaps

5. Tools for Busbar Maintenance

- Thermal imaging camera: Detects hot spots and weak joints

- Torque wrench: Ensures correct connection tightness

- Insulation tester: Measures resistance between busbars and ground

- Surface cleaning tools: Removes oxidation or dust buildup

- Protective coatings: Extend lifespan and prevent corrosion

6. Lifetime Extension Strategies

- Use laminated busbars to reduce inductance and improve reliability

- Apply epoxy or heat shrink insulation for extra safety

- Upgrade connections with silver-plated terminals for better conductivity

- Design for future expansion by oversizing busbars slightly

- Adopt predictive maintenance with IoT-based monitoring sensors

7. Real-Life Example

In an industrial manufacturing plant, busbars showed repeated overheating near a junction. Thermal imaging revealed hot spots due to insufficient torque on bolts. By re-torquing connections, applying anti-oxidation paste, and upgrading to silver-plated busbars, the problem was resolved, extending the busbar lifespan by over 10 years.

8. Preventive vs. Reactive Maintenance

Reactive maintenance after failure is costly and risky. Preventive and predictive maintenance minimize downtime and extend lifespan. Proactive inspection is always more cost-effective than replacing damaged busbars after a fault.

Conclusion

Busbar maintenance is not complicated, but it requires discipline and consistency. By following a structured inspection schedule, addressing common problems early, and investing in protective measures, you can significantly extend the service life of your busbar system. A well-maintained busbar system means safer, more efficient, and more reliable power distribution for decades.