Choosing Between Smart and Conventional PV Combiner Boxes: A Practical Comparison

The growing adoption of photovoltaic (PV) systems has sparked the development of increasingly advanced electrical components. One of the most critical components in a solar power system—the PV combiner box—has evolved from a passive junction box to a data-rich smart monitoring device. This transformation has created two major categories: smart PV combiner boxes and conventional (or standard) combiner boxes.

This article offers a comprehensive, side-by-side comparison of smart and traditional PV combiner boxes. Whether you are designing a residential rooftop, a commercial installation, or a utility-scale solar farm, understanding the differences can help optimize your system’s performance and return on investment.

1. What Is a PV Combiner Box?

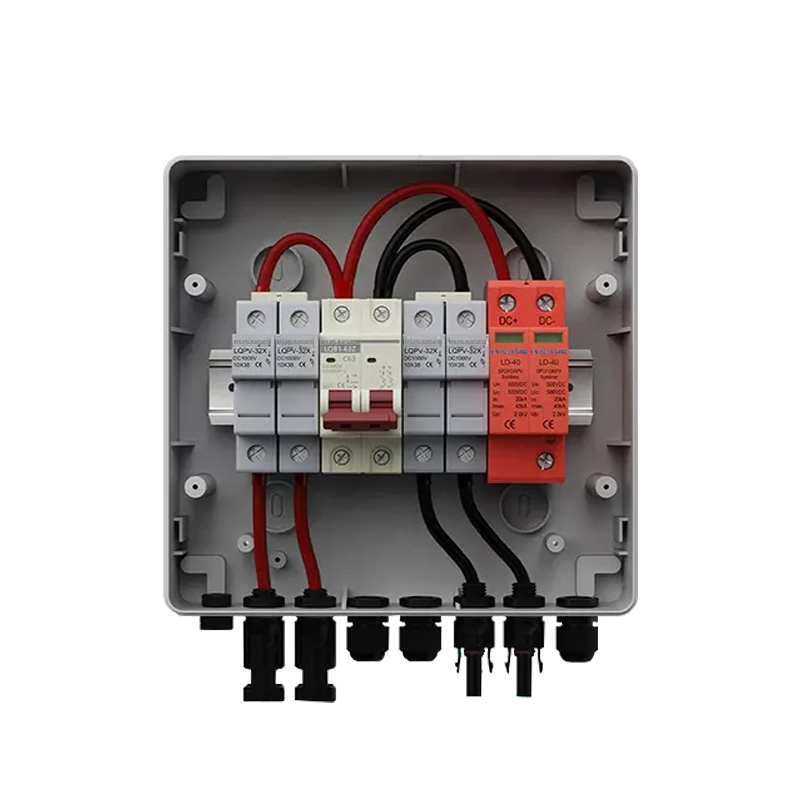

A PV combiner box connects multiple strings of solar panels and combines their DC outputs into a single feed for the inverter. It also houses critical protective devices such as fuses, surge protection devices (SPDs), disconnect switches, and grounding terminals.

2. What Is a Smart PV Combiner Box?

Unlike traditional units, a smart PV combiner box includes electronic components that allow real-time data collection, performance tracking, and even automated alerts. It essentially integrates a miniature data acquisition system into the combiner box.

3. Key Differences Between Smart and Traditional Combiner Boxes

| Feature | Smart Combiner Box | Traditional Combiner Box |

|---|---|---|

| Monitoring | String-level current/voltage, real-time diagnostics | Manual inspection only |

| Data Interface | Modbus, RS485, Ethernet | None |

| Surge Protection | Advanced SPD with status indicators | Basic SPD |

| Maintenance | Proactive, condition-based | Reactive, time-based |

| Cost | Higher initial cost, lower O&M | Lower initial cost, higher long-term O&M |

4. Use Case Comparison

4.1 Residential Rooftop Systems

For small-scale installations with 1–4 strings, traditional combiner boxes are often sufficient. The simplicity and low cost make them ideal for residential use where monitoring is not mission-critical.

4.2 Commercial Systems

Medium-scale systems benefit from smart combiner boxes for their ability to provide real-time fault detection and performance monitoring, helping to reduce unexpected downtime.

4.3 Utility-Scale Projects

Large projects with 100kW+ capacities require advanced diagnostics, making smart combiner boxes indispensable. Integration with SCADA systems and predictive maintenance strategies is crucial at this scale.

5. Advantages of Smart Combiner Boxes

- Early fault detection through string-level monitoring

- Improved energy yield via real-time performance optimization

- Remote access for O&M teams

- Reduced troubleshooting time and field visits

- Data collection for warranty and performance analysis

6. When to Use Traditional Combiner Boxes

- When budget constraints are strict and system size is small

- In systems with minimal string diversity or shading risks

- Where remote monitoring is not required

- When local maintenance staff are readily available

7. Cost-Benefit Analysis

Although smart PV combiner boxes cost 30–50% more initially, the operational benefits can lead to total cost savings over the system’s lifetime. Reduced maintenance labor, higher uptime, and automated alerts all contribute to a quicker return on investment (ROI), especially for large commercial systems.

8. Common Features in Smart Combiner Boxes

- Integrated string monitoring (0–20A sensors)

- Voltage imbalance alerts

- SPD health diagnostics

- Internal temperature tracking

- Firmware-upgradeable controllers

- RS485 or Ethernet communication protocols

9. Compliance and Certifications

Smart and conventional combiner boxes must meet the same safety and compliance standards, such as:

- UL 1741 (U.S.)

- IEC 61439 (International)

- NEC Article 690

- IP65/NEMA 4X enclosure standards for outdoor use

10. Frequently Asked Questions

Q1: Can I upgrade a traditional combiner box to a smart one?

Retrofitting is possible but usually not cost-effective due to wiring complexity and controller integration. It’s best to select smart boxes at the design stage.

Q2: Do smart combiner boxes require internet access?

No, they typically use Modbus/RS485 or Ethernet for local SCADA integration. However, remote monitoring requires network connectivity.

Q3: Are smart combiner boxes harder to maintain?

Not necessarily. In fact, they make maintenance easier through automated alerts and fault codes, reducing guesswork.

11. Final Recommendations

For small-scale or budget-restricted projects, conventional PV combiner boxes are still a solid choice. But for commercial and utility-scale systems, smart PV combiner boxes provide significant value in long-term energy production, O&M efficiency, and system visibility.

Always evaluate your project size, monitoring needs, and ROI expectations before choosing the right combiner box type.