How to Troubleshoot and Maintain PV Combiner Boxes for Long-Term Efficiency

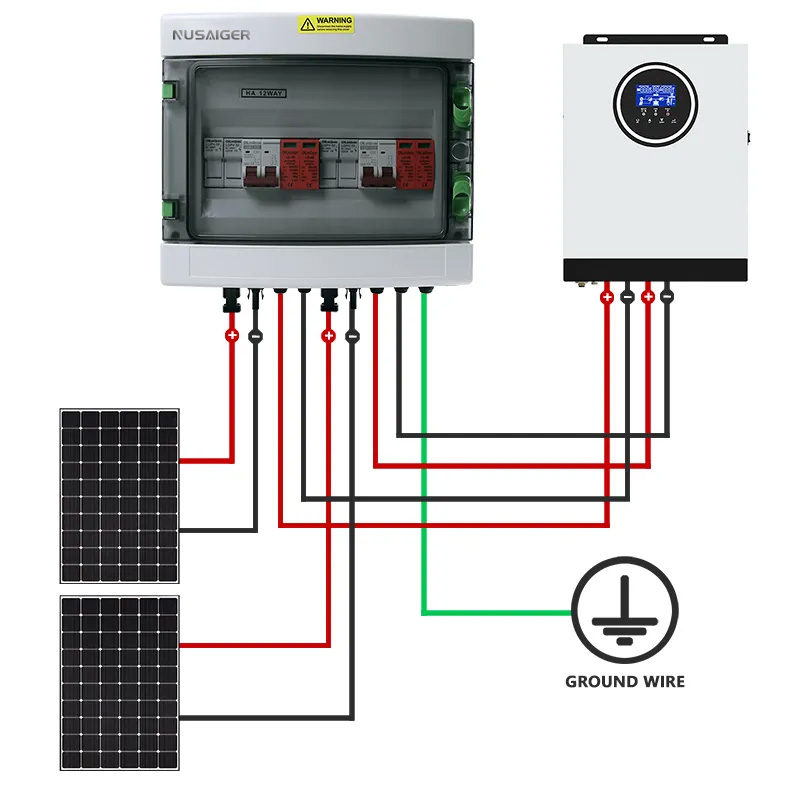

Maintaining the health of a photovoltaic (PV) system is crucial for ensuring long-term energy efficiency and financial returns. One often-overlooked yet vital component of this system is the PV combiner box. This unit consolidates input from multiple solar strings, making it a central point for system monitoring, circuit protection, and maintenance. In this guide, we’ll dive into detailed troubleshooting techniques and preventive maintenance strategies to keep your combiner box operating flawlessly.

1. Understanding Common Issues in PV Combiner Boxes

Combiner boxes are subject to wear, environmental stress, and electrical faults. The most common issues include:

- Loose connections leading to arcing or inconsistent power output.

- Tripped fuses or breakers indicating overcurrent or fault conditions.

- Water ingress due to poor sealing or degraded enclosure integrity.

- Corrosion from moisture or poor-quality materials.

2. Routine Visual Inspections

Regular visual inspections are your first line of defense. Check for:

- Discoloration around terminals, which may indicate overheating.

- Frayed or burned wires suggesting a short circuit.

- Signs of pest infestation, especially in outdoor setups.

- Label clarity and legibility for future servicing.

Conduct these inspections monthly for commercial systems and quarterly for residential arrays.

3. Thermal Imaging

Using a thermal camera during sunny hours can help identify abnormal heat spots, which often signal high resistance or failing components. Compare readings to baseline data to track component degradation over time.

4. Electrical Testing

Use a multimeter or insulation tester to verify:

- Voltage consistency across inputs and output.

- Proper grounding and insulation resistance.

- Continuity across fuses and breakers.

Ensure the system is de-energized before testing to avoid injury.

5. Cleaning and Debris Removal

Dust, dirt, and insects can obstruct airflow or short terminals. Use compressed air and anti-static brushes to clean the interior, and avoid using water unless the box is powered off and waterproof-rated.

6. Component Replacement Strategy

Proactive replacement of aging components (e.g., fuses, terminals, and surge arresters) minimizes unscheduled downtime. Create a component lifecycle plan and keep spares of common parts.

7. Firmware and Monitoring Integration

For advanced combiner boxes with smart monitoring, ensure the firmware is updated and all data logs are reviewed regularly. Abnormal trends in voltage or temperature may indicate early-stage failures.

8. Safety Considerations

Always follow lock-out/tag-out (LOTO) procedures, wear Class 0+ gloves for DC systems, and verify voltage absence with appropriate meters. Safety is paramount during any inspection or repair.

Conclusion

A well-maintained PV combiner box ensures the reliability and performance of your entire solar power system. By implementing regular inspection, testing, and replacement routines, you reduce risks, lower maintenance costs, and extend the lifespan of your photovoltaic array. Whether you’re managing a residential rooftop system or a large-scale commercial solar farm, diligent care of your combiner boxes pays off in uninterrupted clean energy production.