Comprehensive Busbar Installation Guide: Best Practices for Safe and Efficient Power Distribution

Busbars are integral components in power distribution systems, providing a safe and efficient means of distributing electricity in residential, commercial, and industrial environments. Proper installation is critical to ensuring optimal performance, minimizing downtime, and preventing safety hazards. This comprehensive guide covers everything you need to know about installing busbars—from planning and materials to safety practices and optimization techniques.

1. Understanding the Role of Busbars

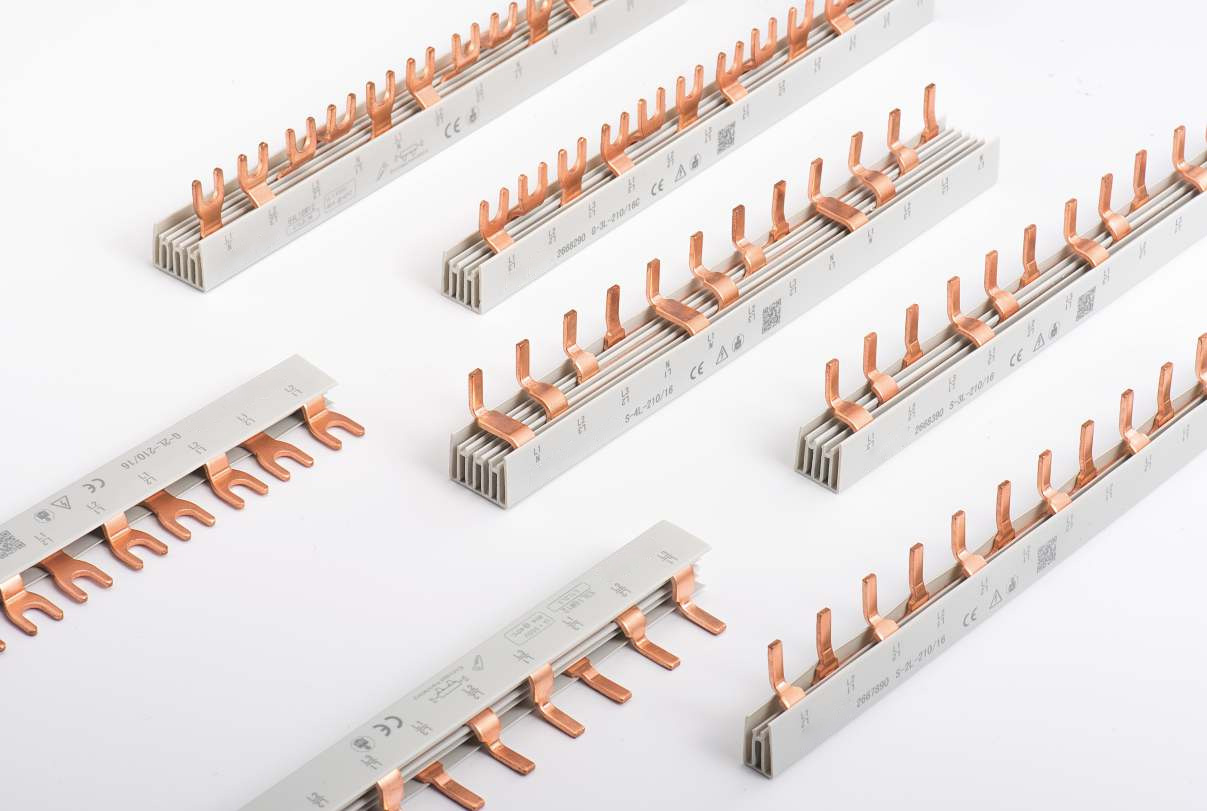

Busbars serve as conductors that collect and distribute electric power to various circuits. Unlike traditional wiring systems, they are rigid, compact, and capable of carrying high currents. Their use simplifies circuit layouts, enhances energy efficiency, and improves system reliability.

2. Planning the Busbar System

Effective busbar installation begins with strategic planning. Here’s what to consider:

- Load Calculation: Determine the total load the busbar will carry, including future expansion.

- Material Selection: Choose between copper and aluminum based on conductivity, budget, and environmental conditions.

- Size and Shape: Decide on flat, hollow, or edgewise configurations based on enclosure space and heat dissipation needs.

- Voltage Level: Ensure the busbar system supports the operational voltage without risk of flashover or dielectric breakdown.

3. Installation Site Requirements

Before installing busbars, confirm that the site meets these critical criteria:

- Proper ventilation to avoid overheating

- Structural support for busbar weight

- Protection from moisture, dust, and chemical exposure

- Accessibility for inspection and maintenance

4. Safety Standards and Compliance

Busbar installations must comply with international safety standards such as IEC 61439, UL 857, and NEC guidelines. This includes:

- Clearance and creepage distance

- Insulation rating and dielectric strength

- Proper earthing and bonding

- Overcurrent and short circuit protection

5. Step-by-Step Installation Process

- Preparation: Lay out drawings and specifications, gather tools and safety gear, and inspect all components.

- Mounting the Busbars: Secure the busbars to insulating supports inside the panel or cabinet. Ensure spacing aligns with current rating and voltage level.

- Connection: Use torque-controlled fasteners and properly rated terminals. Avoid sharp bends or excessive force.

- Insulation and Covering: Apply heat shrink sleeves or epoxy coatings. Enclose the system in protective panels or barriers.

- Testing: Conduct insulation resistance tests, continuity checks, and thermal imaging for hotspots.

6. Optimizing Busbar Performance

To ensure long-term efficiency and safety, consider the following best practices:

- Minimize Joint Resistance: Use silver- or tin-plated contacts and keep surfaces clean.

- Thermal Management: Install cooling fans or ventilation slots to dissipate heat.

- Modular Design: Allow for easy expansion and replacement of busbar segments.

- Regular Maintenance: Schedule periodic inspections to detect corrosion, fatigue, and electrical faults.

7. Common Installation Mistakes to Avoid

Even minor errors can lead to major safety risks or performance issues. Watch out for:

- Incorrect torque on bolts leading to overheating

- Inadequate insulation or spacing

- Improper alignment causing mechanical stress

- Using undersized busbars for high-current applications

8. Conclusion

Installing a busbar system requires meticulous attention to detail, adherence to safety standards, and a deep understanding of power distribution principles. When executed correctly, a well-installed busbar system delivers unmatched efficiency, scalability, and reliability across all electrical infrastructures.

9. Frequently Asked Questions (FAQs)

- Q: How long does it take to install a busbar system?

A: It depends on the complexity of the system, but typical installations range from several hours to several days. - Q: Are copper busbars better than aluminum?

A: Copper offers superior conductivity and durability but is more expensive. Aluminum is lighter and more cost-effective for certain applications. - Q: Can I install busbars outdoors?

A: Yes, but you must use weatherproof enclosures and corrosion-resistant materials.