Comprehensive Guide to Busbar Systems in Modern Electrical Infrastructure

As the demand for efficient and reliable electrical systems grows in both commercial and industrial settings, busbar systems have become an indispensable component of modern electrical infrastructure. This guide explores the purpose, design, types, benefits, and applications of busbars, offering an all-encompassing perspective for engineers, architects, facility managers, and industry professionals.

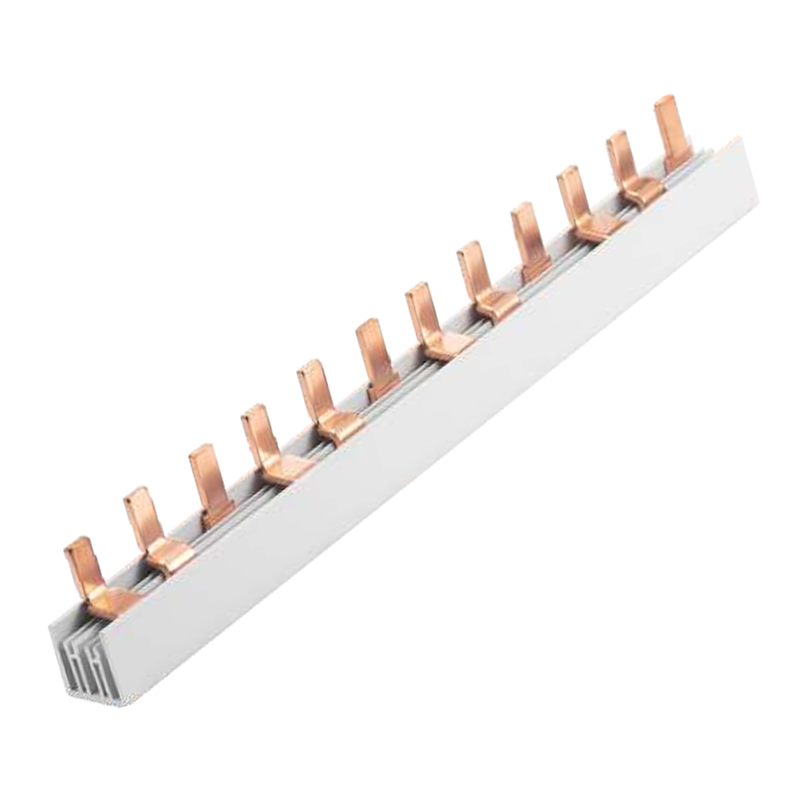

1. What Is a Busbar?

A busbar is a metallic strip or bar used to conduct electricity within a distribution board, switchboard, substation, or other electrical apparatus. It serves as a centralized point to collect and distribute power to multiple circuits or electrical loads. Busbars are typically made from copper or aluminum due to their excellent conductivity.

The name “busbar” is derived from “bus” in electrical terminology, meaning a conductor that serves as a common connection for two or more circuits. The bar-like structure ensures a compact and space-efficient design, making busbars ideal for large-scale power systems where reliability, heat management, and current handling are paramount.

2. Evolution of Busbar Technology

The concept of busbars dates back to early power distribution systems in the 19th century. Traditional busbars were rudimentary metal strips mounted in open-air configurations. Over the years, technology has significantly improved, leading to the development of insulated busbars, compact busbar trunking systems, and prefabricated modular busbars that enhance safety, reduce space usage, and streamline installation.

Modern busbar systems now incorporate advanced materials, fire-resistant coatings, and are designed to withstand high fault currents. With increasing demand for modularity and renewable integration, busbars are now engineered with future-proofing in mind.

3. Types of Busbars

3.1. Copper Busbars

Copper busbars are widely used in high-performance applications due to their excellent conductivity and mechanical strength. Their high current-carrying capacity and resistance to corrosion make them ideal for mission-critical environments like data centers and industrial plants.

3.2. Aluminum Busbars

Aluminum busbars are a cost-effective alternative to copper, with a lower weight and price point. Although they have slightly lower conductivity, aluminum busbars are still widely used in commercial buildings and medium-voltage applications where weight and budget constraints are a concern.

3.3. Insulated Busbars

These are busbars covered with insulation materials to prevent accidental contact and arc flash risks. Insulated busbars are crucial in compact electrical panels where spacing is limited and operator safety is a top priority.

3.4. Flexible Busbars

Flexible busbars are made of layered thin conductors or woven structures, offering high flexibility for installations in constrained or dynamic environments. These are especially useful in battery storage systems, electric vehicles, and solar inverter connections.

3.5. Sandwich Busbars

Sandwich busbars, also known as laminated busbars, consist of multiple layers of conductors separated by insulating films and compressed together. They offer low inductance and are suitable for high-frequency or power electronics applications.

4. Materials Used in Busbars

The most common materials used in busbar manufacturing are:

- Copper: Offers high conductivity, strength, and durability. Often used in premium installations.

- Aluminum: Lightweight and cost-effective. Needs proper surface treatment to avoid oxidation.

- Brass: Sometimes used in low-current applications requiring good corrosion resistance.

- Silver/Gold Coating: In high-reliability systems, a silver or gold coating may be applied to copper busbars to enhance conductivity and corrosion resistance.

The choice of material depends on cost, electrical requirements, weight constraints, and environmental conditions.