Copper vs. Aluminum Busbars: Which One Should You Choose?

When designing an electrical system, selecting the right material for your busbar is crucial. Copper and aluminum are the two primary materials used, each with unique benefits and drawbacks.

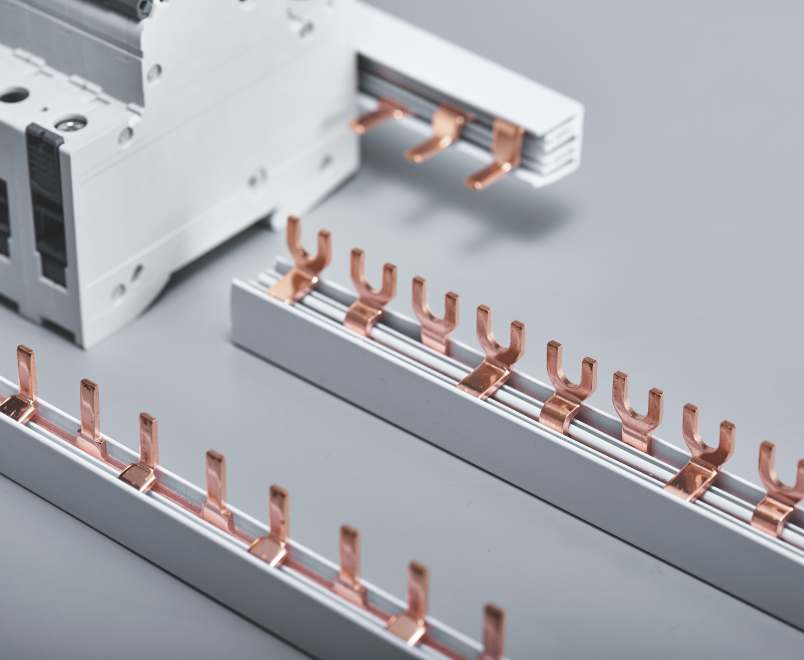

Copper Busbars

Copper busbars are known for their superior conductivity and corrosion resistance. They are ideal for heavy-duty electrical systems and environments with high humidity or temperature fluctuations.

Aluminum Busbars

Aluminum is a more affordable and lighter alternative to copper. While it has lower conductivity, proper design and surface treatment can make it suitable for many commercial applications.

Comparison Table

| Property | Copper | Aluminum |

|---|---|---|

| Conductivity | High | Moderate |

| Cost | Higher | Lower |

| Weight | Heavier | Lighter |

| Corrosion Resistance | Excellent | Requires Coating |

Conclusion

The choice between copper and aluminum busbars depends on your application’s budget, performance needs, and environment. For reliability and efficiency, copper is ideal. For cost-sensitive or lightweight designs, aluminum is a smart alternative.