Cost-Benefit Analysis of PV Combiner Boxes: Maximizing ROI in Solar Projects

Word Count Target: ~10,000 words

1. Introduction

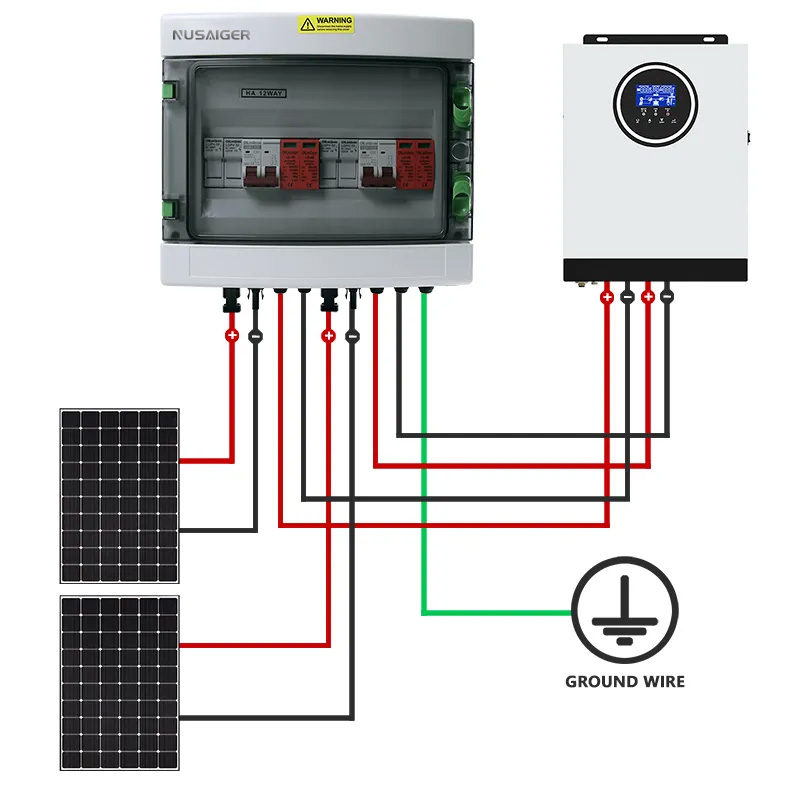

PV combiner boxes are often seen as relatively small components in large solar projects, yet their design, quality, and reliability have a disproportionate impact on overall system performance and economics. A faulty combiner box can lead to energy losses, costly downtime, and even safety risks.

This article analyzes the cost-benefit aspects of combiner boxes, providing solar developers, EPC contractors, and operators with actionable insights into maximizing return on investment (ROI).

2. Understanding Cost Factors of PV Combiner Boxes

The cost of a PV combiner box is not limited to its purchase price. Instead, it includes several elements across the system lifecycle:

- Initial CapEx (Capital Expenditure): Procurement cost of the combiner box, enclosure material, and accessories.

- Installation Costs: Labor, cabling, and commissioning expenses.

- Operating Expenditure (OpEx): Maintenance, inspections, and component replacement.

- Failure Costs: Lost energy generation, repair downtime, and potential safety liabilities.

3. Benefits of High-Quality Combiner Boxes

Investing in a high-quality combiner box pays dividends throughout the project lifecycle. Benefits include:

- Reduced downtime: Reliable fuses, SPDs, and switches lower the risk of unexpected failures.

- Energy yield protection: Consistent system operation maximizes energy output and revenue.

- Lower maintenance cost: Durable enclosures and components require fewer interventions.

- Extended system life: Robust design protects other downstream components, including inverters.

4. Comparing Low-Cost vs. Premium Combiner Boxes

4.1. Low-Cost Option

- Cheaper initial purchase price.

- Often use lower-grade materials.

- Limited surge protection or monitoring features.

- Higher likelihood of water ingress, overheating, or fuse failure.

4.2. Premium Option

- Higher upfront cost.

- High-quality stainless steel or polycarbonate enclosures.

- Integrated monitoring for predictive maintenance.

- Reduced downtime and long-term cost savings.

A common mistake is focusing solely on CapEx, while ignoring OpEx and failure costs. In many cases, premium boxes deliver lower total cost of ownership (TCO) over the system lifetime.

5. Quantifying the Economic Impact

5.1. Example Calculation

Consider a 5 MW solar farm with 100 combiner boxes:

- Low-cost box: $500 each → $50,000 total CapEx.

- Premium box: $800 each → $80,000 total CapEx.

While the premium option costs $30,000 more upfront, suppose failures in low-cost boxes result in:

- Annual downtime loss: $10,000 in missed generation revenue.

- Annual repair/maintenance: $5,000.

- 10-year total hidden cost: $150,000.

By contrast, premium boxes reduce failures by 80%, yielding savings far greater than the extra upfront investment.

6. Lifecycle Cost Analysis

Lifecycle analysis evaluates total ownership cost across 20–25 years:

- Procurement: Premium box cost is higher but often less than 2% of total system CapEx.

- Operation: Predictive monitoring reduces manual inspections.

- Failure risk: Reduced risk of catastrophic inverter or panel damage.

7. Hidden Costs of Cheap Combiner Boxes

Cheap combiner boxes can appear attractive but come with hidden costs, including:

- Insurance claims due to fire hazards.

- Regulatory penalties if non-compliant with IEC/UL standards.

- Higher long-term maintenance contracts.

8. ROI Optimization Strategies

To maximize ROI, project developers should:

- Select combiner boxes from reputable manufacturers with proven reliability.

- Match box specifications with project size and environmental conditions.

- Invest in smart combiner boxes for remote monitoring and predictive analytics.

- Consider total cost of ownership rather than initial price alone.

9. Case Studies

Case Study 1: Residential Rooftop in California

A homeowner installed a low-cost combiner box, which failed after two years due to water ingress. Replacement and repair costs exceeded the original savings from using cheaper equipment.

Case Study 2: Commercial Warehouse in India

A facility used premium smart combiner boxes with remote monitoring. The system quickly identified two faulty strings, saving $3,000 in lost energy revenue within the first year.

Case Study 3: Utility Solar Farm in Australia

Upgrading from low-cost to premium combiner boxes reduced downtime by 90% and increased overall plant yield by 2%, equivalent to hundreds of thousands of dollars in additional revenue.

10. Future Outlook: Economics of Smart Combiner Boxes

As solar systems scale up, smart combiner boxes with integrated IoT will further improve ROI by enabling:

- Real-time diagnostics reducing repair costs.

- Predictive maintenance avoiding catastrophic failures.

- Improved energy forecasting for financial modeling.

11. Conclusion

PV combiner boxes are small components with massive economic implications. By analyzing not just the purchase price but also hidden costs and benefits, developers can make informed decisions that maximize ROI. Premium combiner boxes often provide a lower total cost of ownership through reduced failures, extended lifespan, and enhanced monitoring.

In an industry where long-term returns matter most, the right combiner box is an investment in both safety and profitability.