Designing a Reliable PV Combiner Box: What Engineers Should Consider

A well-designed PV combiner box can significantly impact the overall efficiency and safety of a solar installation. It’s not just about combining strings; it’s about ensuring long-term reliability, code compliance, and ease of maintenance.

Key Components of a Reliable Design

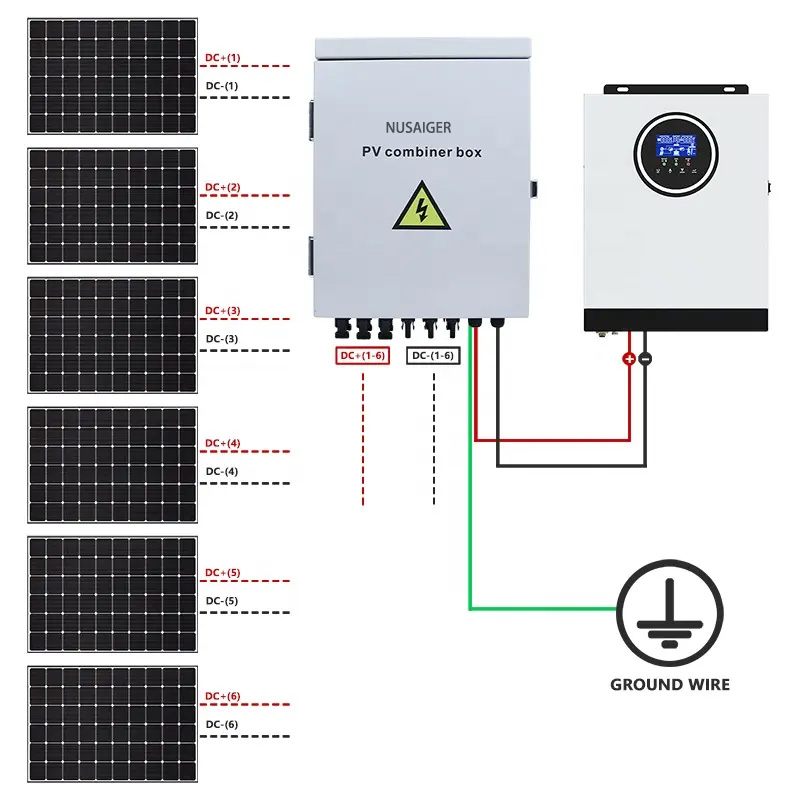

1. Input String Configuration

Match the number of string inputs to system layout. Avoid over- or under-designing.

2. Fuse and Breaker Selection

Choose fuses based on maximum current. Underrated fuses can overheat; oversized fuses may not protect the system.

3. Surge Protective Devices (SPDs)

Select SPDs depending on regional lightning risks and compliance standards.

4. Enclosure Material

Use weatherproof, UV-stabilized, IP65+ rated enclosures like stainless steel or aluminum.

5. Internal Layout

Ensure efficient busbar spacing, heat dissipation, and clear terminal access.

Relevant Standards

- IEC 61439-1/2

- UL 1741

- NEC Article 690

Conclusion

Designing a PV combiner box requires careful electrical, thermal, and mechanical planning. A robust design ensures decades of safe and efficient solar operation.