Everything You Need to Know About Busbars: A Comprehensive Guide for Electrical Professionals

Introduction

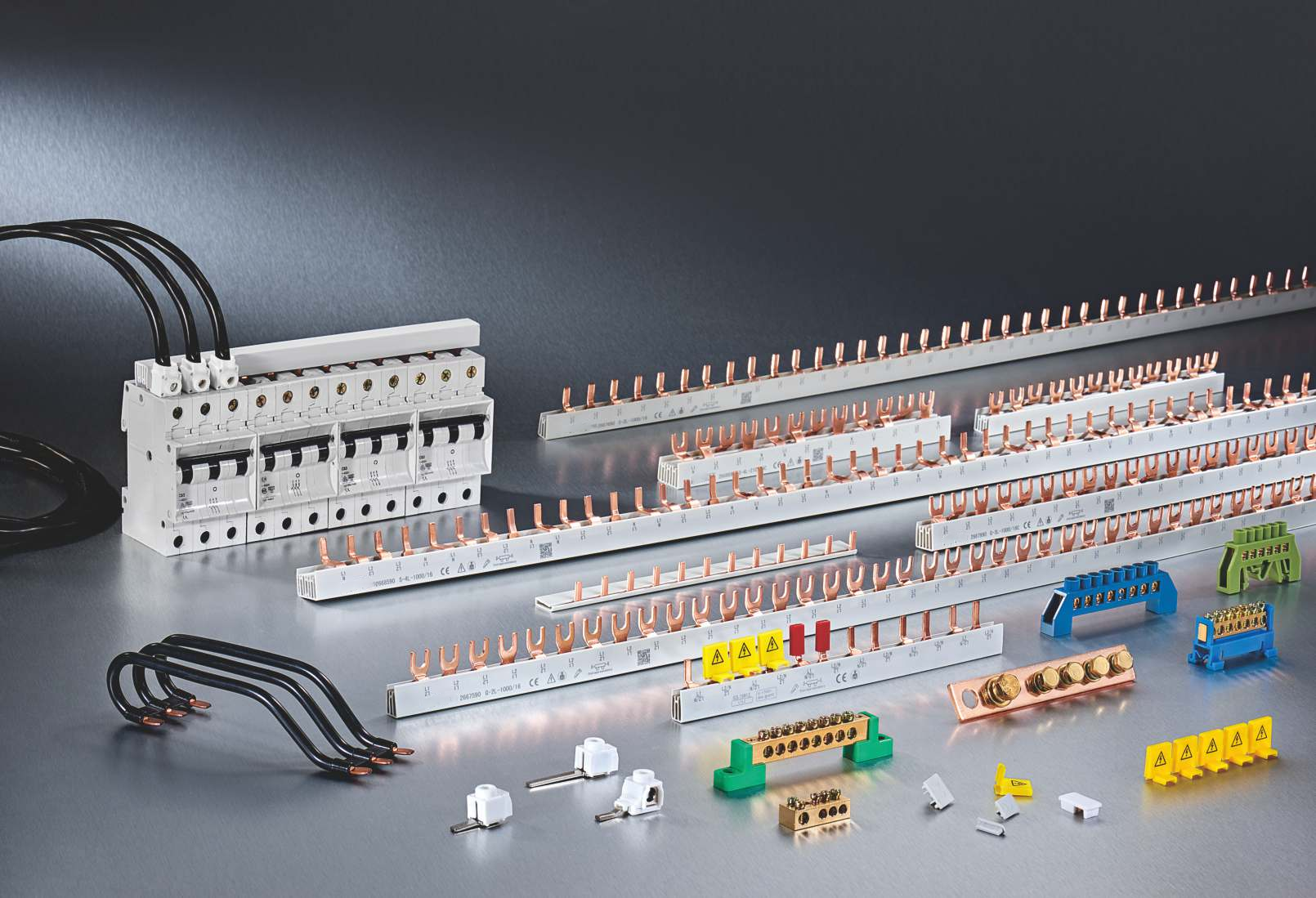

Busbars are the silent backbone of modern electrical systems, essential for distributing large amounts of power in both industrial and commercial applications. From switchgear assemblies to data centers, busbars offer a reliable, compact, and scalable solution for power distribution. In this comprehensive guide, we will explore everything you need to know about busbars—including types, materials, design considerations, applications, and safety guidelines.

What is a Busbar?

A busbar (also spelled bus bar) is a metallic strip or bar made from copper, aluminum, or other conductive materials used for high-current power distribution. It acts as a central point where power is collected and distributed to multiple circuits. Busbars are widely used in panel boards, switchgear, transformers, UPS systems, and more.

Types of Busbars

- Copper Busbars: High conductivity, excellent corrosion resistance, often used in critical infrastructure.

- Aluminum Busbars: Lightweight and cost-effective, commonly used in large-scale distribution systems.

- Laminated Busbars: Made of layered sheets for compact installations with lower inductance.

- Flexible Busbars: Designed for vibration-prone or movable components like transformers or motors.

Busbar Materials: A Detailed Comparison

| Material | Conductivity | Weight | Cost | Application |

|---|---|---|---|---|

| Copper | High | Heavy | Expensive | Data centers, power plants |

| Aluminum | Moderate | Light | Affordable | Utility grids, substations |

| Laminated | High | Medium | Medium | EVs, aerospace, compact units |

Busbar Design Considerations

- Current rating and ampacity

- Voltage drop across terminals

- Insulation type (heat shrink, epoxy coating, air insulation)

- Clearance and creepage distance

- Thermal expansion and mechanical support

Common Applications of Busbars

Busbars are crucial in various sectors:

- Power generation: Turbine and generator bus systems

- Industrial plants: Motor control centers and process lines

- Data centers: Busbar trunking for high-efficiency distribution

- Renewable energy: Busbars in solar combiner boxes and wind inverters

Installation Best Practices

- Always disconnect power before installation.

- Use appropriate torque for terminal connections.

- Ensure proper insulation and earthing.

- Use busbar supports and spacers to avoid short circuits.

- Perform routine maintenance checks for corrosion or overheating.

Busbar Safety and Compliance Standards

Busbar systems should comply with IEC 61439, UL 857, or equivalent regional standards. Key safety guidelines include:

- Proper insulation and fire resistance

- Short circuit withstand capacity

- Electromagnetic compatibility

- Thermal and dielectric testing

Benefits of Using Busbars

- Compact and space-saving design

- Higher mechanical strength and thermal performance

- Lower maintenance compared to cable systems

- Faster installation and scalability

Challenges and Limitations

- High initial cost, especially for copper-based systems

- Requires skilled technicians for installation

- Thermal management in enclosed spaces

Conclusion

Busbars are an essential part of the electrical infrastructure, offering numerous advantages in efficiency, safety, and reliability. Whether you’re designing a switchgear room or planning a renewable energy system, understanding busbar technology is vital to ensure performance and compliance. Investing in the right busbar system will reduce long-term costs and enhance operational safety.