How to Test and Maintain Surge Protective Devices: A Complete Guide

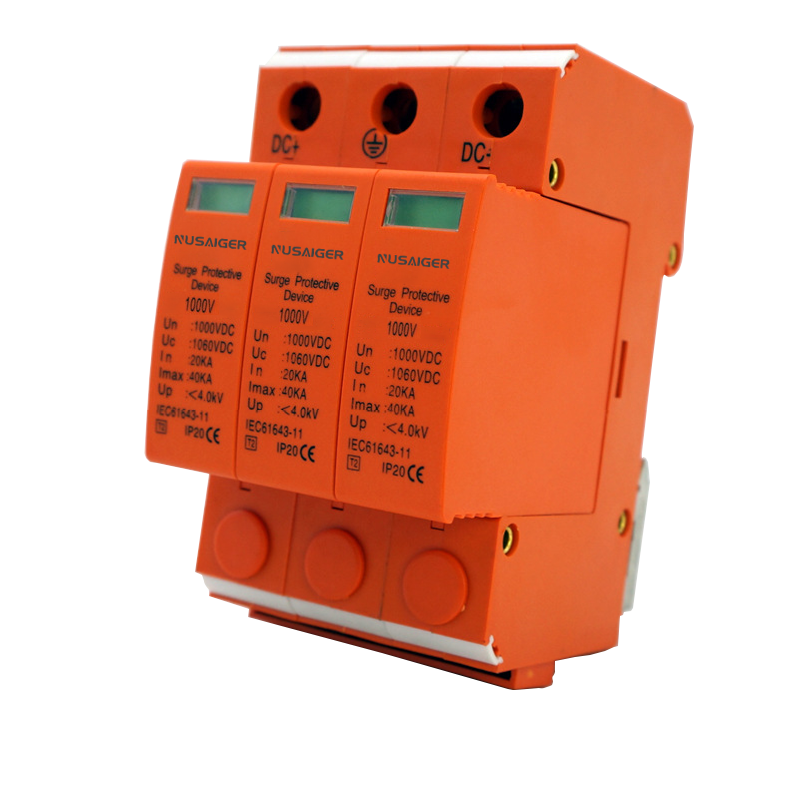

Surge protective devices (SPDs) are the frontline defense against transient voltage spikes caused by lightning strikes, power grid switching, and other electrical disturbances. While choosing the right SPD is essential, proper maintenance and regular testing are critical to ensure your system remains fully protected over time.

1. Why Surge Protective Device Maintenance Is Crucial

SPDs are subject to degradation over time, especially in areas with frequent surges or poor power quality. Without proper maintenance, an SPD might silently fail, leaving your equipment vulnerable. Regular inspection and testing can help you detect early signs of failure and prevent catastrophic equipment loss.

1.1 The Hidden Risks of Neglect

- Undetected failures due to internal damage

- False sense of security while devices are non-functional

- Gradual performance degradation over years

- Warranty invalidation due to lack of maintenance records

2. Understanding the SPD Lifecycle

SPDs are not “fit-and-forget” devices. Every SPD has a limited lifespan, usually rated in terms of the number and intensity of surges it can absorb. Factors that affect lifespan include:

- Installation environment

- Surge intensity and frequency

- SPD technology (MOV-based, gas discharge tube, hybrid, etc.)

- Quality and manufacturer reliability

3. When Should SPDs Be Tested?

Regular testing ensures functionality and early detection of deterioration. Ideal testing intervals include:

- Every 6 to 12 months for critical facilities

- After major lightning events

- Following any system fault or abnormal operation

- During routine electrical system maintenance

4. Tools and Equipment for SPD Testing

Professional SPD testing may require specialized equipment:

- Insulation resistance testers: For checking insulation breakdown

- Clamp meters: For checking leakage currents

- Continuity testers: For basic circuit checks

- SPD monitoring systems: Built-in diagnostics for smart SPDs

5. Step-by-Step Guide to SPD Testing

- Step 1: Disconnect power and follow lockout/tagout procedures

- Step 2: Visually inspect the SPD for any damage, discoloration, or loose connections

- Step 3: Measure voltage between terminals to confirm safe de-energization

- Step 4: Use a continuity tester to check for open circuits

- Step 5: For plug-in SPDs, test replaceable modules if applicable

- Step 6: Reconnect the SPD, verify proper operation, and restore power

6. SPD Maintenance Best Practices

- Log all maintenance activities for future reference

- Replace damaged SPDs immediately — even minor failures can render them useless

- Install surge counters for high-risk environments to monitor cumulative surges

- Clean SPD housing and terminals regularly to avoid corrosion or thermal buildup

7. Common Signs That an SPD Needs Replacement

- Visible burn marks or melted casing

- Tripped breakers or fuses linked to SPD lines

- Alarm from SPD monitoring system

- Significant deviation in clamping voltage during tests

- Loose or damaged wiring

8. Preventive Maintenance Checklist

| Activity | Frequency | Responsible Party |

|---|---|---|

| Visual inspection | Quarterly | Facility maintenance team |

| Functional test | Every 6-12 months | Electrical engineer |

| Surge counter reading | Monthly | Supervisor or technician |

| Cleaning and retightening connections | Every 6 months | Maintenance staff |

9. Integrating Maintenance into Your Electrical Safety Program

Incorporating SPD testing into your facility’s routine electrical maintenance ensures that surge protection becomes part of a holistic safety approach. It reduces unplanned downtimes, protects assets, and ensures compliance with industry standards such as:

- IEC 61643-1 (Low-voltage SPD standard)

- UL 1449 (SPD safety certification)

- NFPA 70 (National Electrical Code)

10. Final Thoughts: Don’t Wait Until It’s Too Late

SPDs silently protect your equipment every day. However, neglecting their maintenance turns them into ticking time bombs — they may look intact while being non-functional. Regular inspection, scheduled testing, and swift replacement of degraded units are your best bet for keeping your electrical system secure.

Conclusion

Surge protective devices are a small but essential investment for the long-term safety of your electrical infrastructure. Whether you manage a commercial building, a solar power system, or an industrial facility, proper SPD testing and maintenance can save you from unexpected outages and costly repairs. Always follow manufacturer recommendations and industry standards for inspection and replacement intervals.

Need Expert Help?

If you’re unsure about how to test or maintain your SPD systems, contact our technical support team. We offer professional SPD assessments, monitoring solutions, and certified replacement parts tailored to your application needs.