Innovative Busbar Solutions for Industrial Power Distribution: Trends and Best Practices

Industrial power distribution systems demand robust, efficient, and flexible solutions to manage ever-increasing electrical loads safely. Busbars serve as the backbone for such systems, enabling streamlined power flow, enhanced reliability, and scalability. This article delves into innovative busbar technologies, design trends, and maintenance techniques critical for optimizing industrial electrical infrastructure.

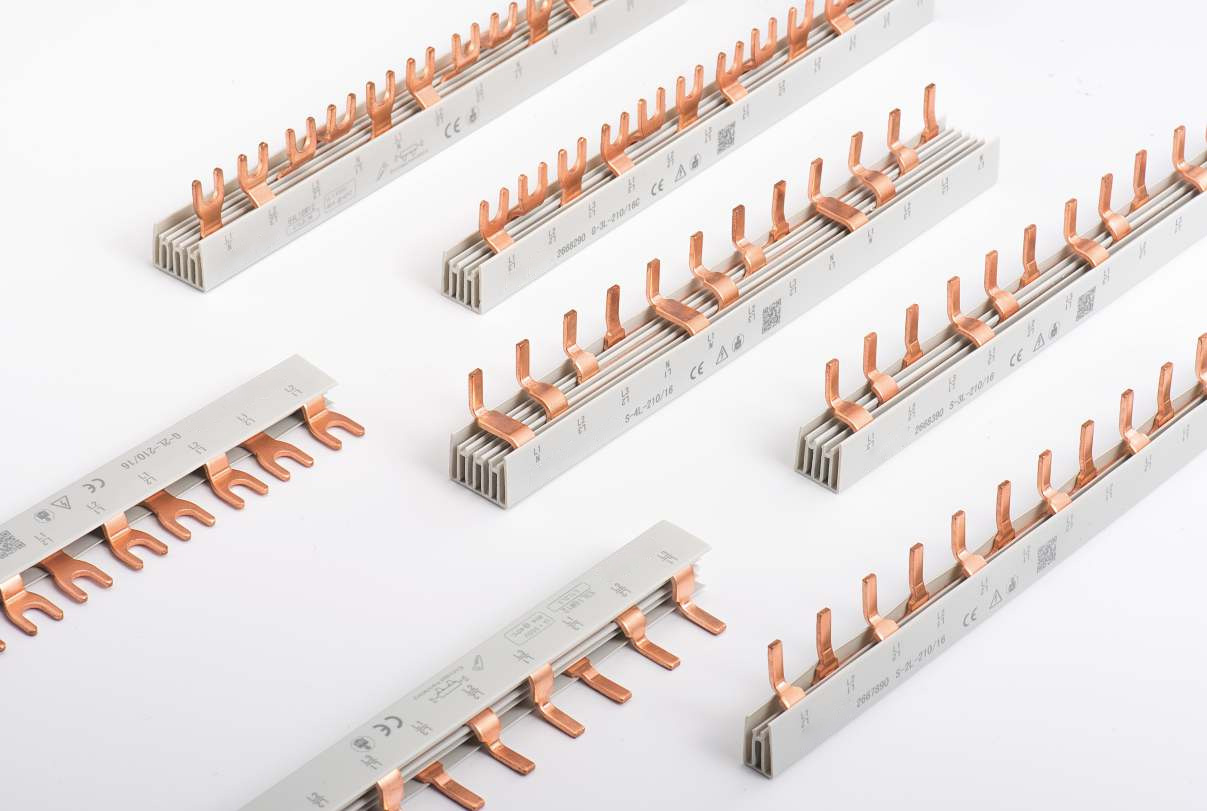

1. The Role of Busbars in Industrial Power Distribution

Busbars distribute electrical power efficiently from transformers to switchgear and from switchgear to equipment. Their design allows the safe transfer of large currents with minimal losses, essential in industrial environments where downtime can be costly.

2. Modern Materials and Their Impact

While copper remains a popular choice for its conductivity and durability, aluminum busbars offer significant weight and cost savings. Additionally, emerging composite materials and advanced coatings improve corrosion resistance and thermal performance.

3. Modular Busbar Systems for Industrial Flexibility

Modularity in busbar design allows for easier upgrades, expansions, and repairs. Prefabricated modules reduce installation time and provide standardized, reliable connections.

4. Innovations in Busbar Insulation

New insulation materials, such as advanced epoxy resins and cross-linked polyethylene (XLPE), offer superior dielectric strength and thermal stability, critical in harsh industrial settings.

5. Installation Best Practices

- Ensure proper torque on connections to avoid hotspots.

- Use insulated supports and maintain adequate clearances.

- Incorporate thermal monitoring systems for early fault detection.

- Plan for ease of maintenance and access in design phases.

6. Maintenance and Monitoring Strategies

Regular inspections, infrared thermography, and predictive maintenance using IoT-enabled sensors help detect potential failures before they cause downtime.

7. Compliance with Standards and Regulations

Adhering to IEC 61439, IEEE, and local safety standards ensures reliability and protects personnel.

8. Case Study: Busbar Upgrades in Automotive Manufacturing Plant

An automotive plant implemented a modular copper busbar system, reducing power losses by 15% and maintenance downtime by 25%, highlighting the effectiveness of modern busbar technology.

9. Future Trends in Industrial Busbars

Integration with smart grids, digital twins, and AI-driven analytics will revolutionize power distribution, making busbars smarter and more adaptive.

Conclusion

Innovative busbar solutions are vital for the evolving demands of industrial power distribution. Investing in modern materials, modular designs, and proactive maintenance strategies ensures operational excellence and long-term cost savings.