The Role of PV Surge Protective Devices in Utility-Scale Solar Power Plants

1. Introduction

Utility-scale solar plants face unique challenges compared to residential or commercial PV systems. With larger arrays, longer DC runs, and higher system voltages (1000–1500 VDC), the risk of damage from lightning strikes and switching surges increases significantly. A PV Surge Protective Device (SPD) is essential to safeguard sensitive equipment, minimize downtime, and maintain high energy yield.

In this article, we will explore the role of PV SPDs in utility-scale plants, highlight best practices, and provide real-world examples of effective surge protection strategies.

2. Challenges in Utility-Scale PV Systems

- High DC voltages up to 1500 VDC increase the potential impact of surges.

- Long cable runs can lead to voltage drop and surge amplification.

- Thousands of PV modules create multiple points susceptible to lightning strikes.

- Centralized inverters require robust protection to avoid costly downtime.

- Maintenance access can be challenging, making SPD reliability critical.

3. Importance of SPDs in Large PV Plants

PV SPDs protect utility-scale solar plants in several ways:

- Protect Inverters: SPDs prevent transient overvoltages from damaging expensive inverter electronics.

- Protect Combiner Boxes: Limit surge currents aggregating from multiple strings.

- Reduce Downtime: Minimize the risk of system failure during lightning events.

- Ensure Safety: Prevent fire hazards or insulation breakdown caused by high voltage surges.

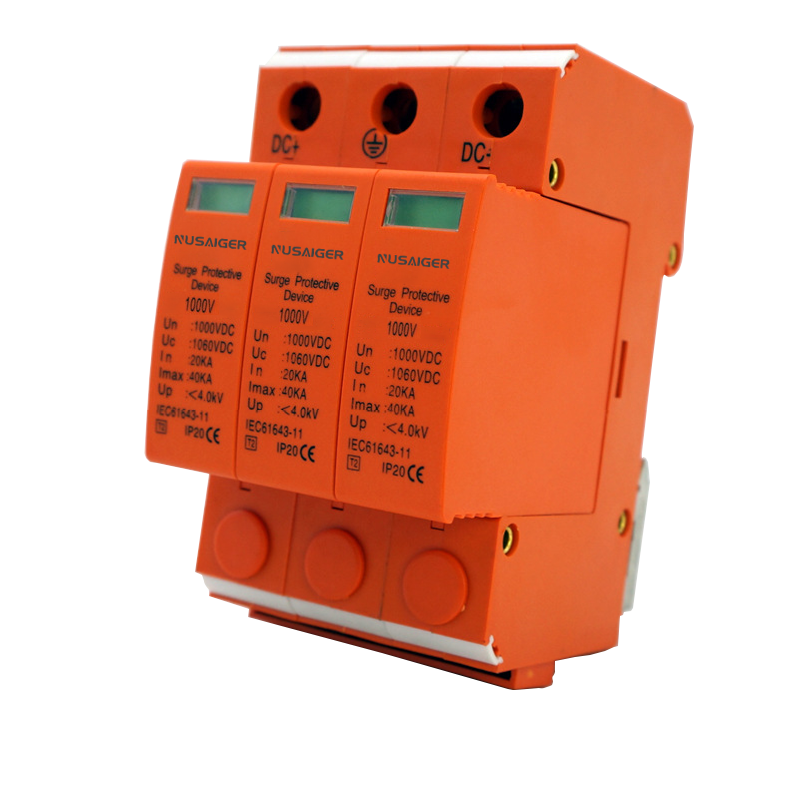

4. SPD Types for Utility-Scale Systems

Utility-scale PV plants often implement a layered SPD approach:

- Type 1 SPDs: Installed at the plant service entrance to protect against direct lightning strikes.

- Type 2 SPDs: Installed at combiner boxes and inverter DC inputs to protect against indirect surges.

- Type 3 SPDs: Optional localized protection for sensitive monitoring equipment.

Coordinating these SPDs ensures comprehensive surge protection across all system levels.

5. Key Considerations for SPD Selection

- Rated DC voltage (Uc) should match system voltage, typically 1500 VDC.

- Nominal discharge current (In) should support frequent surges, usually ≥ 20 kA for large systems.

- Maximum discharge current (Imax) must withstand lightning strikes, often 40–60 kA.

- Low clamping voltage (Up) ensures equipment is protected within safe voltage limits.

- Thermal disconnection or end-of-life indicator for maintenance purposes.

6. Installation Best Practices in Utility-Scale Plants

- Install SPDs as close as possible to the equipment being protected.

- Use low-impedance grounding conductors for surge diversion.

- Minimize lead lengths between SPD and equipment to reduce voltage spikes.

- Coordinate SPDs across array, combiner boxes, and inverters.

- Implement remote signaling to monitor SPD status for preventive maintenance.

7. Monitoring and Maintenance

Large PV plants require ongoing monitoring to ensure SPDs function as intended:

- Visual inspection for discoloration or damage

- End-of-life indicators and remote monitoring alarms

- Routine testing and verification after major storms

- Replacement of SPDs that have reached end-of-life or experienced high-energy surges

8. Real-World Case Study

A 200 MW solar farm installed 1500 VDC inverters with coordinated Type 1 and Type 2 SPDs. During a monsoon season, several direct and nearby lightning strikes occurred. The SPDs effectively diverted surge currents, protecting inverters and combiner boxes. The plant continued operation with zero downtime, demonstrating the importance of properly rated and strategically installed SPDs.

9. Conclusion

PV Surge Protective Devices are indispensable for utility-scale solar plants. By selecting the right SPD types, rating parameters, and installation practices, operators can significantly reduce the risk of equipment damage, ensure system reliability, and maintain consistent energy production. Proper SPD planning is a key component in maximizing ROI and long-term safety of large solar farms.