How Surge Protective Devices Minimize Equipment Downtime in Industrial Settings

Unexpected equipment downtime can lead to significant revenue losses in industrial operations. Surge Protective Devices (SPDs) play a critical role in safeguarding sensitive machinery and electrical infrastructure from harmful transient voltages caused by lightning strikes, power surges, or switching operations.

Why SPDs Are Essential in Industrial Applications

Industrial environments often house high-value assets like programmable logic controllers (PLCs), variable frequency drives (VFDs), and automation systems. A single power surge can disrupt operations or cause irreversible equipment failure. SPDs absorb and divert excess voltage away from these devices, acting as a first line of defense.

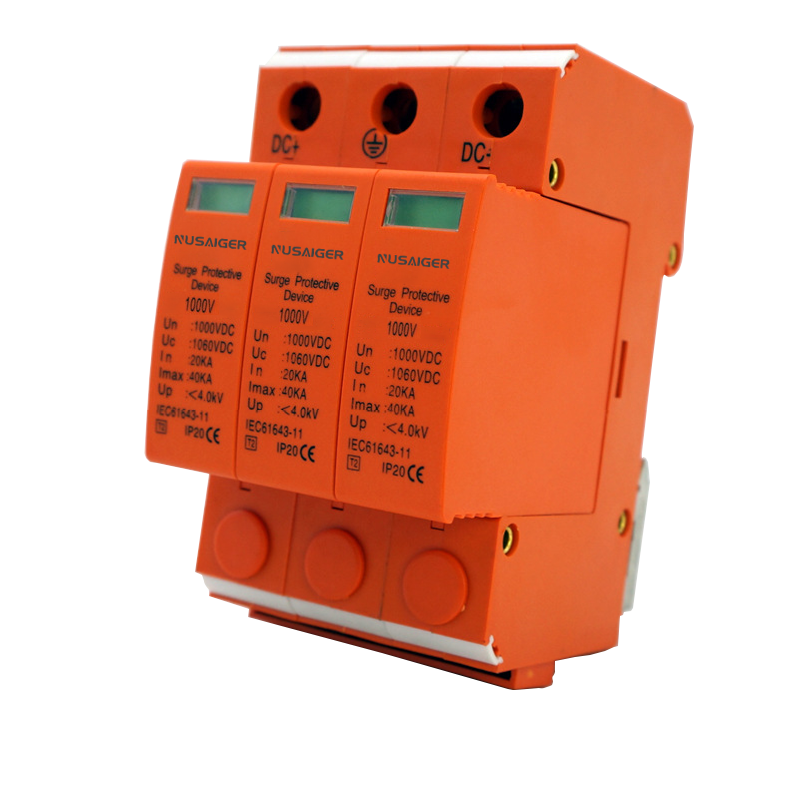

Choosing the Right SPD for Your Facility

Selection depends on system voltage, expected surge exposure, and protection level required. Class I SPDs are ideal for locations with direct lightning exposure, while Class II is typically sufficient for internal protection.

ROI: Preventive Cost vs. Damage Cost

Investing in quality SPDs reduces unexpected repair and replacement costs, protects data integrity, and ensures continuous productivity.

In conclusion, incorporating SPDs into your industrial setup is a cost-effective strategy to prevent downtime, extend equipment lifespan, and improve workplace safety.