The Ultimate Guide to Designing PV Combiner Boxes for Large-Scale Solar Projects

With the rapid growth of utility-scale solar farms, system designers are increasingly focusing on the reliability and scalability of components like PV combiner boxes. A well-designed combiner box not only consolidates string outputs but also ensures the safety, monitoring, and maintainability of a solar PV array. This guide offers an in-depth blueprint on how to design PV combiner boxes that meet the rigorous demands of large-scale installations.

1. Understanding the Role of a PV Combiner Box in Utility-Scale Solar

In large PV systems—typically rated above 1 MW—a PV combiner box becomes an integral part of the electrical distribution network. Each combiner box connects multiple PV strings (up to 24 or more) and outputs a single DC feed to the inverter or DC feeder panel.

Key functions include:

- Combining string outputs into one DC line

- Providing overcurrent protection (string fuses)

- Enabling surge protection

- Facilitating voltage/current monitoring

- Enabling safe isolation during maintenance

2. Sizing a PV Combiner Box: Critical Considerations

Proper sizing ensures safe operation and compliance with electrical codes. Here are the factors to calculate:

- Number of strings: Typical range is 8–24 per box

- Maximum voltage: Common levels are 600V, 1000V, and 1500V DC

- Current per string: Usually 8–15A; box busbars must support total output

- Output cable size: Must match system ampacity and voltage drop limits

Oversizing components may offer future-proofing, but it increases cost. Strike a balance between flexibility and economy.

3. Selecting the Right Enclosure

For utility projects, the environment is often harsh—dust, rain, UV exposure, and even wildlife interference are common. Choose enclosures with:

- IP65 or higher protection level

- UV-stabilized polycarbonate or powder-coated steel

- Double-layer design for thermal insulation (in hot regions)

- Ventilation with filters, if needed

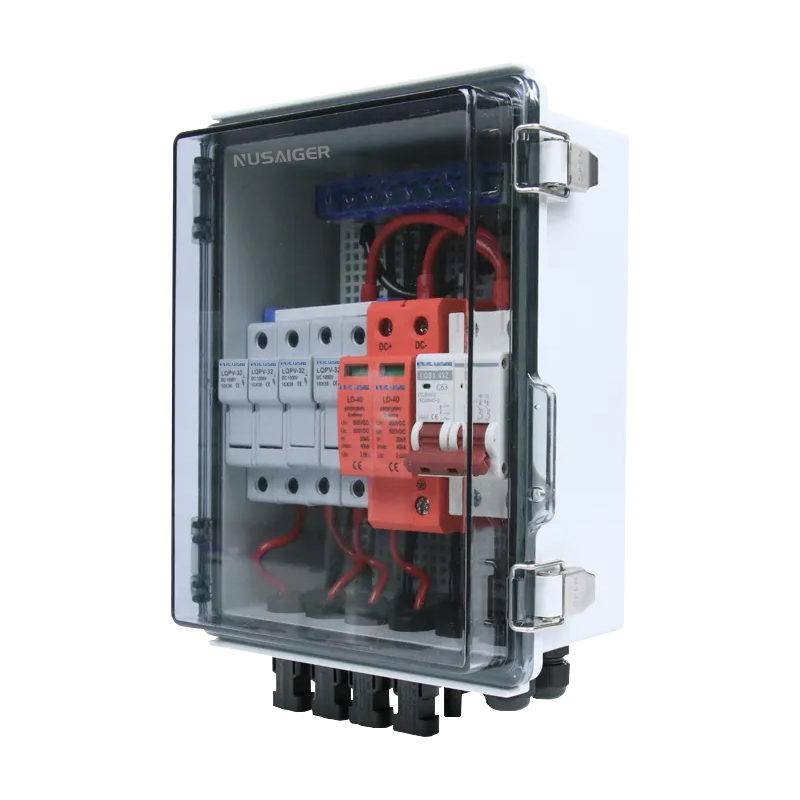

4. Component Specification Checklist

A utility-grade PV combiner box should include:

- Fuse holders: Rated at 1000V or 1500V DC

- String fuses: Sized based on 1.56 × string current (per NEC)

- Surge protection device (SPD): Type 2 DC-rated

- Monitoring unit: Modbus RS485 or Ethernet interface

- DC disconnect switch: Lockable rotary type

- DIN rails and wiring duct: For clean layout

- Cable glands: IP68-rated polyamide or metal

5. Electrical Standards and Certifications

Designing combiner boxes for utility projects must comply with regional standards:

- NEC Article 690 (USA)

- UL 1741 / UL 508A

- IEC 61439-2 (Europe and Asia)

- TUV, CE, or BIS certification

Failure to meet standards can result in rejected inspections and loss of commissioning approval.

6. Thermal Management and Heat Dissipation

High current through busbars and terminals creates heat buildup. Design strategies include:

- Using wide busbars with high copper purity

- Spacing components to allow airflow

- Providing shading or active cooling in extremely hot zones

- Choosing flame-retardant materials rated UL94-V0 or better

7. Wiring and Layout Optimization

Efficient layout prevents electrical interference, heat spots, and maintenance issues. Tips:

- Segregate input and output wiring

- Label all terminals clearly

- Ensure strain relief on heavy DC cables

- Maintain a layout diagram inside the box for reference

8. Safety Features for Utility Compliance

Solar farms must meet stringent safety rules. Include:

- String-level fusing for each input

- Visual fault indicators (blown fuse LEDs)

- Arc-fault detection and mitigation (optional)

- Ground fault detection circuit (optional)

- External handle for emergency shutdown

9. Smart Monitoring and Data Integration

Modern utility-scale PV systems rely on SCADA or EMS for remote supervision. Advanced combiner boxes offer:

- Voltage/current monitoring per string

- Temperature and SPD status sensors

- RS485 or Modbus communication

- Cloud dashboard or on-site HMI

10. Field Installation Best Practices

Incorrect field installation leads to faults or fire risks. Recommendations:

- Mount boxes on galvanized steel structures with concrete bases

- Use only crimped lugs, no loose wires

- Verify torque values on terminals

- Label and document each string connection

- Use lightning arrestors and grounding mesh

11. Maintenance and Lifecycle Considerations

Though passive, combiner boxes require annual checks. Key tasks:

- Thermal inspection with IR camera

- SPD function test (replace after strike)

- Check for rodents or moisture ingress

- Review data logs for anomalies

12. Case Study: 50 MW Solar Plant in India

A 50 MW solar farm in Gujarat used 320 PV combiner boxes across its layout. The project required 1500V-rated boxes with 20-string inputs. Customized monitoring units were installed, and the enclosures were rated IP66 with powder coating for salt fog resistance.

The boxes contributed to 99.6% uptime in the first year, with no DC faults recorded—a testament to good design.

13. Common Design Mistakes and How to Avoid Them

- Undersized SPD for local lightning conditions

- Overloaded busbars due to poor future-proofing

- Unmarked wiring inside box—creates confusion during maintenance

- Improper sealing leading to corrosion and insulation breakdown

- Using aluminum for busbars instead of copper (false economy)

14. Conclusion

Designing PV combiner boxes for utility-scale projects is a technical process that demands careful planning and compliance. Every element—from fuse selection to enclosure materials—affects system performance, cost, and safety.

Engineers and solar EPC contractors should treat the combiner box as a mission-critical asset, not just a junction enclosure. With the right design, your solar project can deliver decades of safe, efficient, and profitable energy output.