Introduction

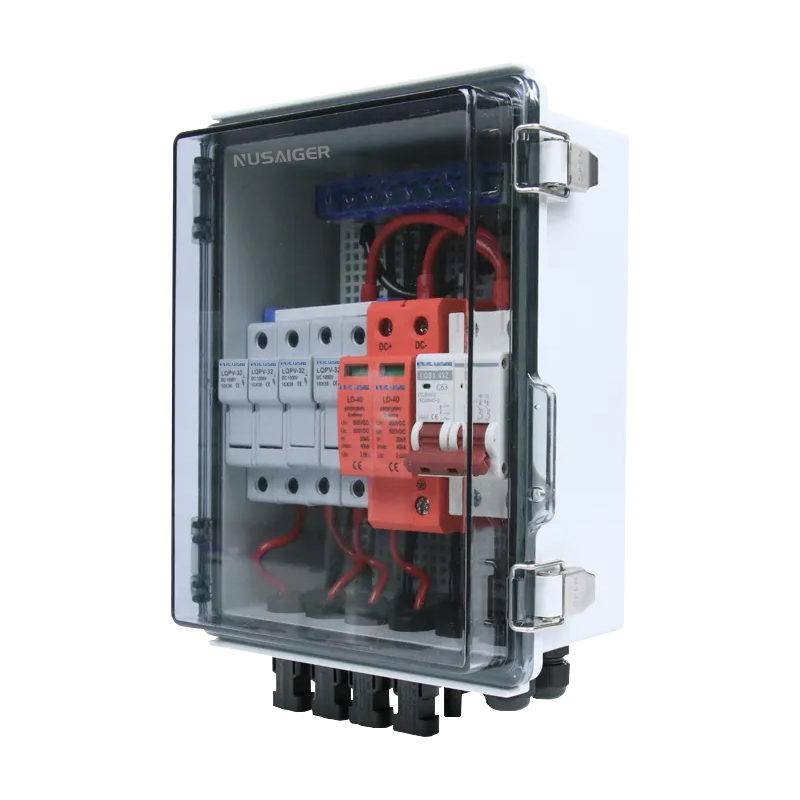

Utility-scale solar installations require much more than just panels and inverters. At the heart of the system’s wiring and energy aggregation is the PV combiner box. Its role becomes even more essential as system size and complexity grow.

Centralized Collection for Efficiency

In a solar farm, each row or group of solar panels (strings) feeds into a combiner box. This centralizes their output into a single feed, minimizing wiring costs and improving layout clarity.

Reduced CAPEX and OPEX

Fewer cables = lower installation costs

Simplified maintenance = reduced operational costs

Fault localization = faster resolution and minimal downtime

Enhanced Safety in Harsh Environments

Large-scale projects often operate in desert, coastal, or high-altitude regions. Industrial-grade combiner boxes offer:

High corrosion resistance

Dust and humidity protection

Internal temperature management

Advanced Data & Communication

Some advanced combiner boxes offer real-time data transmission to centralized SCADA systems. This allows for:

String-level performance analysis

Early detection of degradation or anomalies

Predictive maintenance planning

Case Study Highlight

A 50MW solar farm in Australia integrated 120 PV combiner boxes with built-in string monitoring. The site reported a 15% improvement in maintenance efficiency and reduced power losses by 8%.

Conclusion

In large-scale solar, a reliable PV combiner box isn’t just optional—it’s essential. Choose one built for scalability, durability, and smart management.